E3D’s Revo and ObXidian Nozzles E3D’s Hermes, or now Hemera, introduced a new, compact heatbreak mount. A couple of years later, the reason for that became clear: There’s a whole new ecosystem of hotends, extruders, and integrated nozzlebreaks that all revolve around this new form factor that makes nozzle swaps faster and printing more reliable. E3D was calling it Revo. But… there was a small problem. Only E3D are allowed to make nozzles for it, and the only nozzles they were making were plain brass. Which meant you could onlyContinue reading

How to use a 3DBenchy

Hello from the new, old, old, new studio! I’m not quite fully set up in here yet, but it’s usable, and today we’ll be talking about Benchies! I don’t think I need to explain what this is – if you’re watching this video and you’ve got a 3D printer, you will most likely have already printed a 3DBenchy at some point. And I think that’s great! I’m going to argue that this is pretty much the ultimate calibration or benchmark print. I’ve never printed a calibration cube, well, maybe once,Continue reading

Get the benefits of a 0.6mm nozzle with a 0.4?

My “0.4mm nozzles are obsolete” video apparently left quite a few questions in need of answering, at least going by the comments on the video. So today, we’re going to look at whether you can maybe just stick with a 0.4mm nozzle and tell your slicer to pretend it’s a 0.6, how strength compares between nozzle sizes, and whether comparing 0.4 with an old slicer to 0.6 with a new one was even fair in the first place. I hope I didn’t hurt the nozzles’ feelings. So let’s start outContinue reading

Should you use a Reverse Bowden?

The job of a Bowden tube is to guide the filament from the extruder into the hotend so that the extruder can drive the filament over here, but the actual pushing force happens at the hotend. If this printer didn’t have one, the filament would get pushed just the same, but the driving force wouldn’t be able to push it into the hotend. Makes sense, right? But not every 3D printer is a Bowden system, in fact, this guy isn’t, but I’m going to argue it’s still going to profitContinue reading

Are you printing at the right temperature?

When you start a print, how do you decide what settings to use? Of course, parameters like the solid shell thickness or the infill percentage are something that needs to be decided on a print-by-print basis, but what I mean are the settings that, ideally you figure out once and then leave as a preset for future you. But what if those presets are wrong? What if you didn’t even tune those in yourself and use whatever the filament manufacturer suggests or stick with the presets that come with yourContinue reading

Arachne in PrusaSlicer: 0.4mm Nozzles just became obsolete

I´ve used dozens of different 3D printers over the years. They look like they’re machines that are made for vastly different jobs, based on how they’re built and what they’re capable of. But they all share one thing in common: A 0.4mm nozzle. And the nozzle is one of the core things that make a 3D printer work. But why is it always a 0.4mm bore? Surely with all the different applications these printers are made for, it can’t just be a one-size-fits-all choice. And you’re right, it’s not. Honestly,Continue reading

Hands-off 3D Printing

The eternal quest for that one bed surface that perfectly sticks while printing and completely releases when cold. Many have tried to find it, many have failed, but 3DQue have finally done it. Or at least that’s what they claim for the Quinly system, which promises to turn your humble 3D printer into a global-scale production unit by adding a network gateway that controls your printer and that you can use to queue up prints, a lift kit that angles your machine so that parts can slide off once they’reContinue reading

You made me do this…

This is resonances, part 2. Last time we tried a bunch of approaches, from suspending the printer from the ceiling, bolting it to a concrete paver or sticking it onto some anti-vibration feet. And some of those worked, some didn’t, and my conclusion at the time was that you have to have some sort of dampening element in your setup for it to do anything – otherwise you’re just shifting around the excess energy that causes these vibrations instead of removing it from the system. So to test that theory,Continue reading

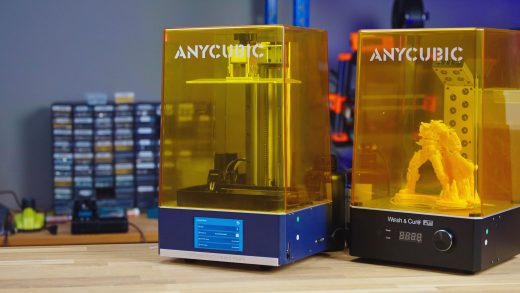

Review: Anycubic Photon M3 Plus

Resin printers, they’re pretty great, right? Well, they’re also mostly all the same, so I get that reviews of yet another Chitubox-based cookie cutter printer aren’t exactly interesting. So I tried to find one that was different – and that’s the Anycubic Photon M3 series. The Anycubic machines all use a custom ecosystem; this is the mid-size M3 Plus, they’ve also got the base M3, which uses a 4K masking LCD, this M3 Plus uses a 6K one and the M3 Max uses a 7K screen. The two larger machines,Continue reading