So you’re considering getting a 3D printer? Well, before I get you too excited with my other video about why you should get one, maybe first consider this video about why you should not get one. There are quite a few things that only become apparent once you’re in deep, and I’ve been in deep for the last decade. So here are five aspects to factor into your decision on whether you should get a 3D printer for yourself or even recommend getting one to a friend.

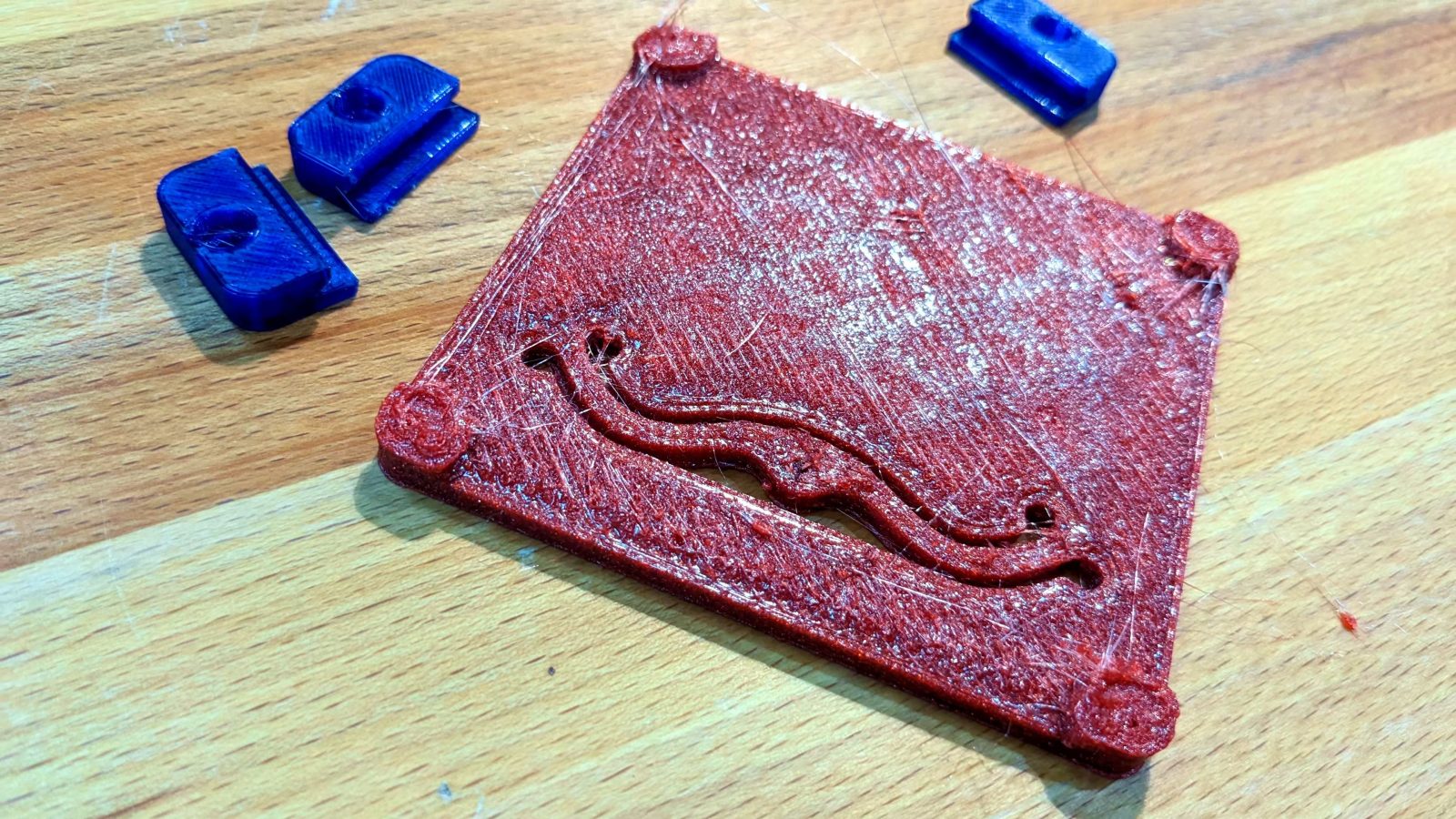

Consideration number one: 3D printing can be quite an absorbent hobby to get into. Sure, you can totally get a machine and just use it to print stuff, but there’s always that little thing that you could tweak or improve or upgrade, and if you’re not careful, you’ll spend most of your time just working on the printer itself and modding that instead of actually using it for its intended purpose. Not that that’s necessarily a bad thing, the intended purpose of some machines is being a hobby and a platform to play around with, but if you end up getting the wrong machine for your use case or are easily lured towards always seeking something just a bit better than what you have, you can easily get lost in that cycle. If the top Google hits for the model you’re considering getting are full of “top 25 upgrades” videos and articles, you’re probably looking at a project, not a tool.

And cheap machines can also fail and degrade over time, for example, the stock Teflon-lined hotend in many of the more basic machines is built in a way that can give you hard-to-diagnose issues after a couple of kilograms of filament, which often lines up with the point where the initial enthusiasm will have worn off and running into a roadblock issue like that may just be enough to end your 3D printing journey as a whole.

And when it comes to diagnosing issues, well, first of all, there are plenty of things that can go wrong, and the way they manifest in the print results can be quite ambiguous, so diagnosing and fixing them does take some expertise, or alternatively, trial and error. And you can’t just rely on the online community to help you out, which brings us to consideration number 2: The community. It’s wild!

So when it comes to finding help online, where most of the interactions happen, you’re not guaranteed to get helpful answers at all. I’ve seen Facebook threads where a pretty obvious printer issue was confidently misdiagnosed a dozen times after which the original poster ended up getting belittled when none of the “fixes” worked for him.

On top of that, many of the discussions online now revolve around “my tribe is better than yours”, where in the wrong groups all you’ll get is fanboys screeching at each other. I mean, some communities even decide it’s a good idea to create Discord channels dedicated exclusively to hating on specific people, and there are 3D-printing YouTubers whose entire point of existence is spreading conspiracy theories.

I guess those are the sorts of issues when any online community has grown big enough, but you definitely don’t want to feed the trolls or get between the hardened fronts of 3D printing loyalists. These days, it’s probably even worse than car guys pecking at each other for driving the wrong brand of car. Speaking of which, Consideration number 3:

3D printing is efficient, but it’s also pretty efficient at making trash. I mean, yes, being a “car guy” and casually guzzling down 20 gallons of dino juice for fun probably is the more wasteful option compared to 3D printing, but ultimately, you’re working with plastics in various forms and every extra gram of material you use will eventually end up in a landfill or getting burnt, even if it has had a useful service life of many years, it is still plastic. Unless you meticulously sort by material and ship your failed or used prints to a dedicated 3D print recycler because it’s unknown and unmarked material, the plastic in 3D prints simply won’t be used in a large-scale recycling scheme. And yes, the most commonly used material, PLA, is based on cornstarch instead of petroleum, that’s better, but it still requires a specialized setup to decompose, otherwise, it’s not going to be much different from “regular” plastic waste.

Resin print materials are thermosets, and for those, there isn’t any viable way to recycle them at all, and on top of being harmful in their uncured, liquid state, you’re also having to use organic solvents to clean and post-process your parts.

In any case, no matter what material you buy for filament or resin printing, it’s still going to come on a spool or in a bottle, plus a vacuum bag, plus a box, plus a shipping box, plus transport and production impacts, there simply is going to be some environmental impact no matter which way you spin it.

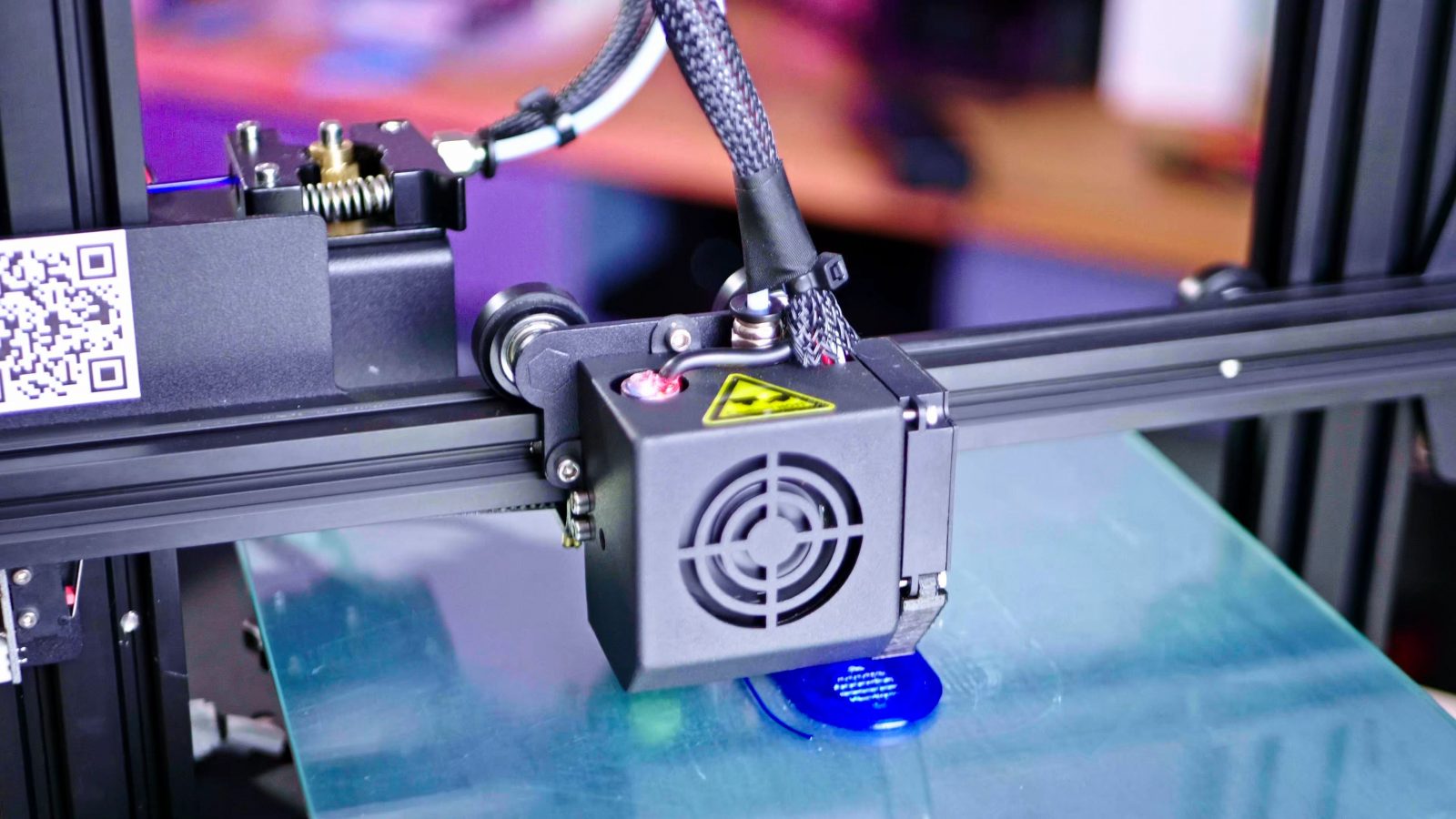

And lastly, consideration number 4, as flexible and “easy to use” 3D printers have become, they’re still actually quite limited when they can only produce /plastic/ parts that, on top of that, for maximum usefulness, you’re going to need to design yourself.

And yes, I’ve only got 4 cons vs. the 5 pros that are in the other video, I’m kind of into 3D printers, so I’m probably biased here, but still, if you go into this entire thing, I would rather get you started with realistic expectations.

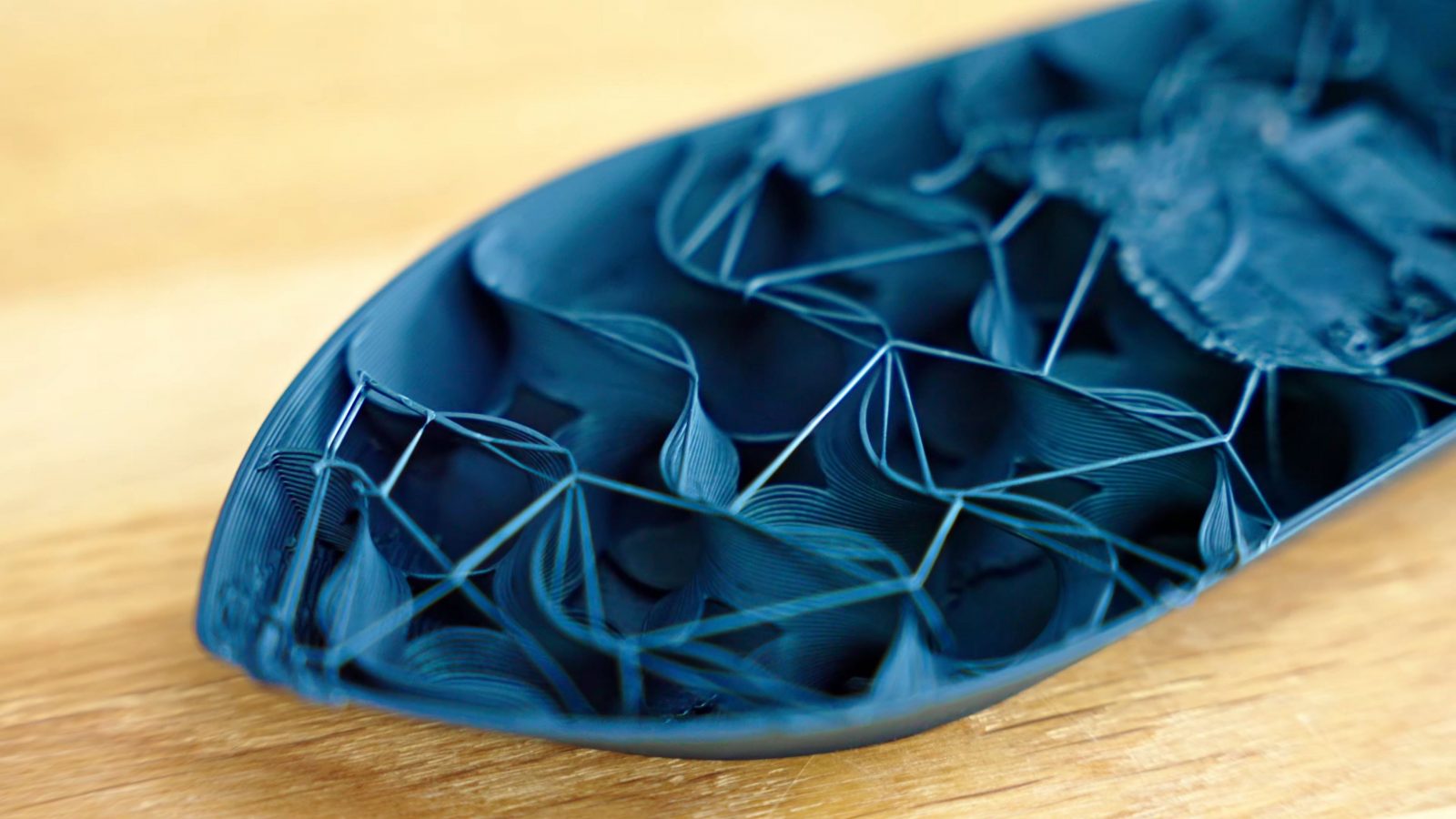

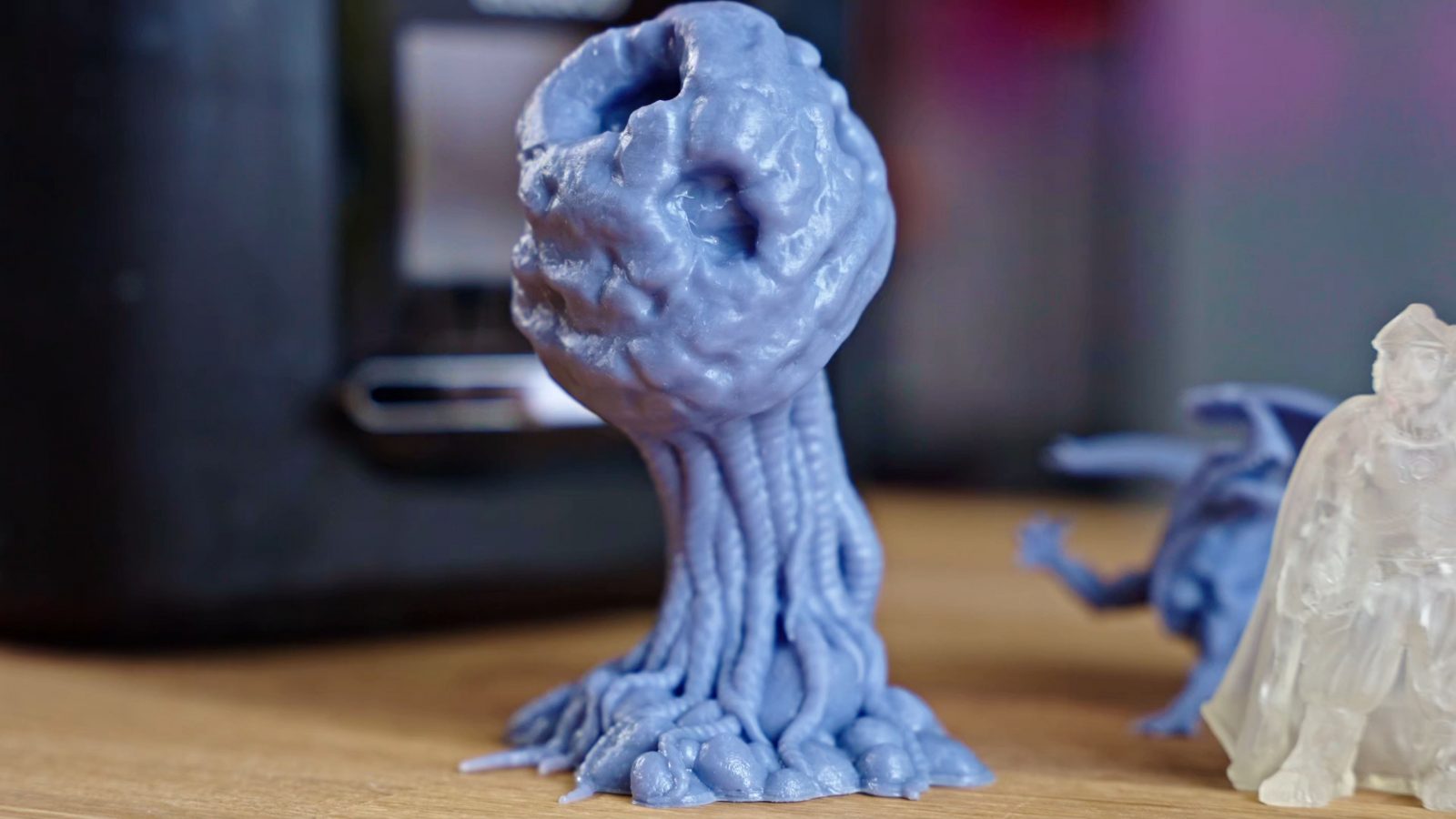

So, yeah, about that, yes, the 3D printers that are in the attainable range for low-cost manufacturing and for hobby use only do plastics. There are varieties out there that are suited for different applications, but at the end of the day, it’s not metal, it’s not an organic material like wood that you’re creating your parts from, it’s simply plastic. Don’t get me wrong, you would probably underestimate how strong fairly basic 3D printed parts can be, but you’re just not going to get the wear resistance, super high strength, or temperature resistance of metals. 3D-printed parts are usually going to be pretty bulky if they need to be strong, and they’re also not going to come with a perfect surface finish. Resin prints do get close to a smooth mass-produced look, but otherwise, unless you spend hours finishing, sanding, and painting your parts, it will always be immediately apparent that you’re looking at a 3D print.

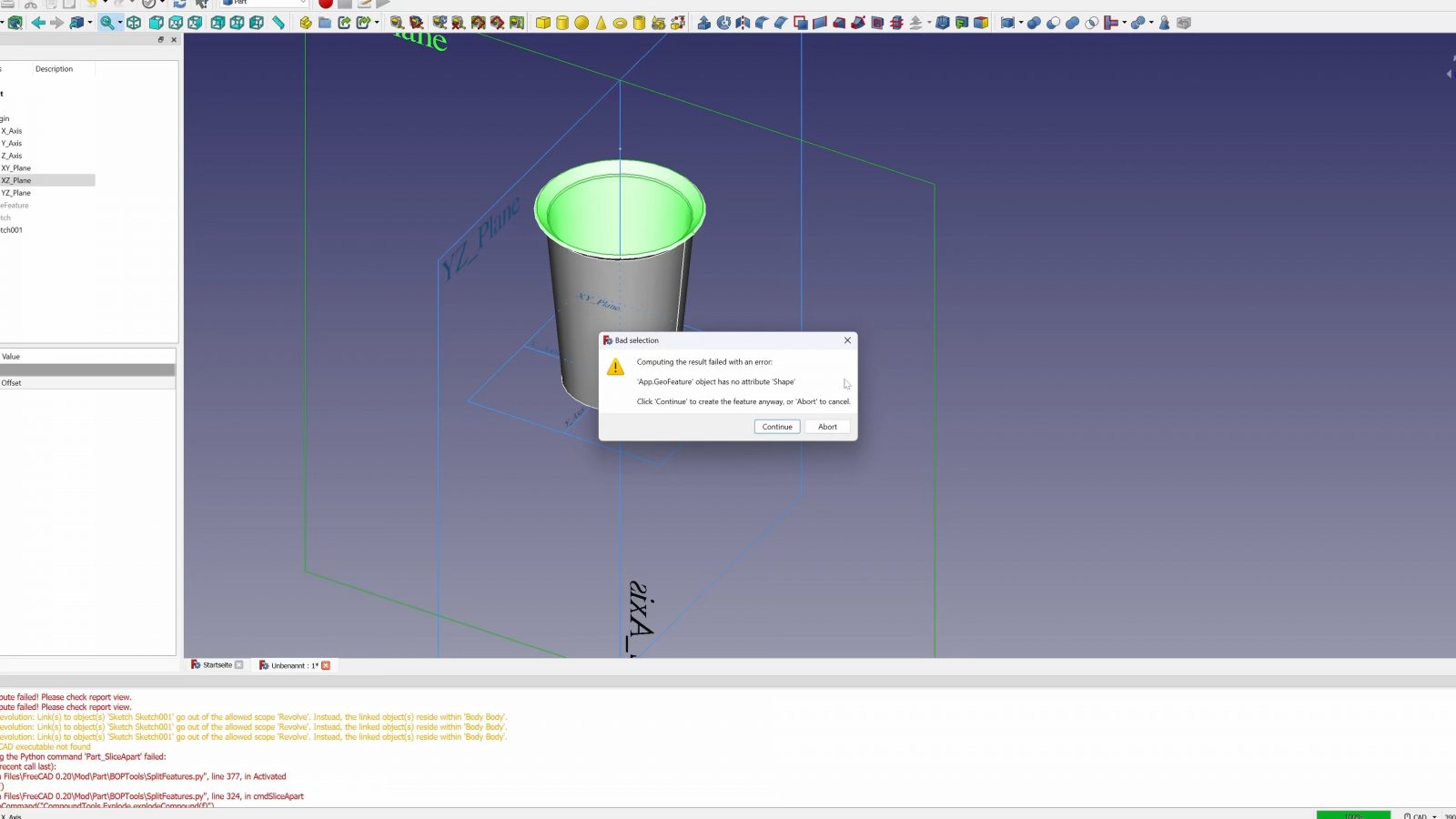

And downloading the designs that other users have created will only get you so far – for me, a 3D printer is only really useful if I’m capable of designing my own parts to print. So on top of having to master the machine and everything that comes with that, you’re essentially having to pick up another completely unrelated skill to make proper use of the machine. If you’re not already versed with the tools to design parts, it can be quite the learning curve and perhaps even a bit too much all at once.

Now, of course, getting into 3D printing is not an impossible task, but you should know what you’re in for and what to watch out for, and hopefully, with the correct expectations, you’re going to have a better time in the end. Check out the video with some of my top reasons why you should get a 3D printer here, if you found this video helpful, like comment subscribe, thanks for watching, keep on making, and I’ll see you in the next one!

💙 Enjoying the videos? Support my work on Patreon!

Product links are affiliate links – I may earn a commission on qualifying purchases (at no extra cost to you)

Check out my second channel “More Layers” on YouTube for livestreams