When the MK3 came out about five years ago now, it was an easy recommendation in a sea of then-mediocre alternatives that took years to catch up. Now the tables have turned, and it’s on Prusa’s machines to catch up. Is the classic Prusa recipe still enough to make the MK4 worth 1200€? I’m not convinced yet, so let’s explore.

Even though they’ve dropped the “Prusa Mendel i3” part of the name, the MK4 still is a continuation of the “Mendel” heritage of Prusa’s printers, and as such, the basic design stays the same – moving bed and all.

And it does feel a lot like the MK3, even though almost every part on the machine has been swapped, upgraded, or changed in some way.

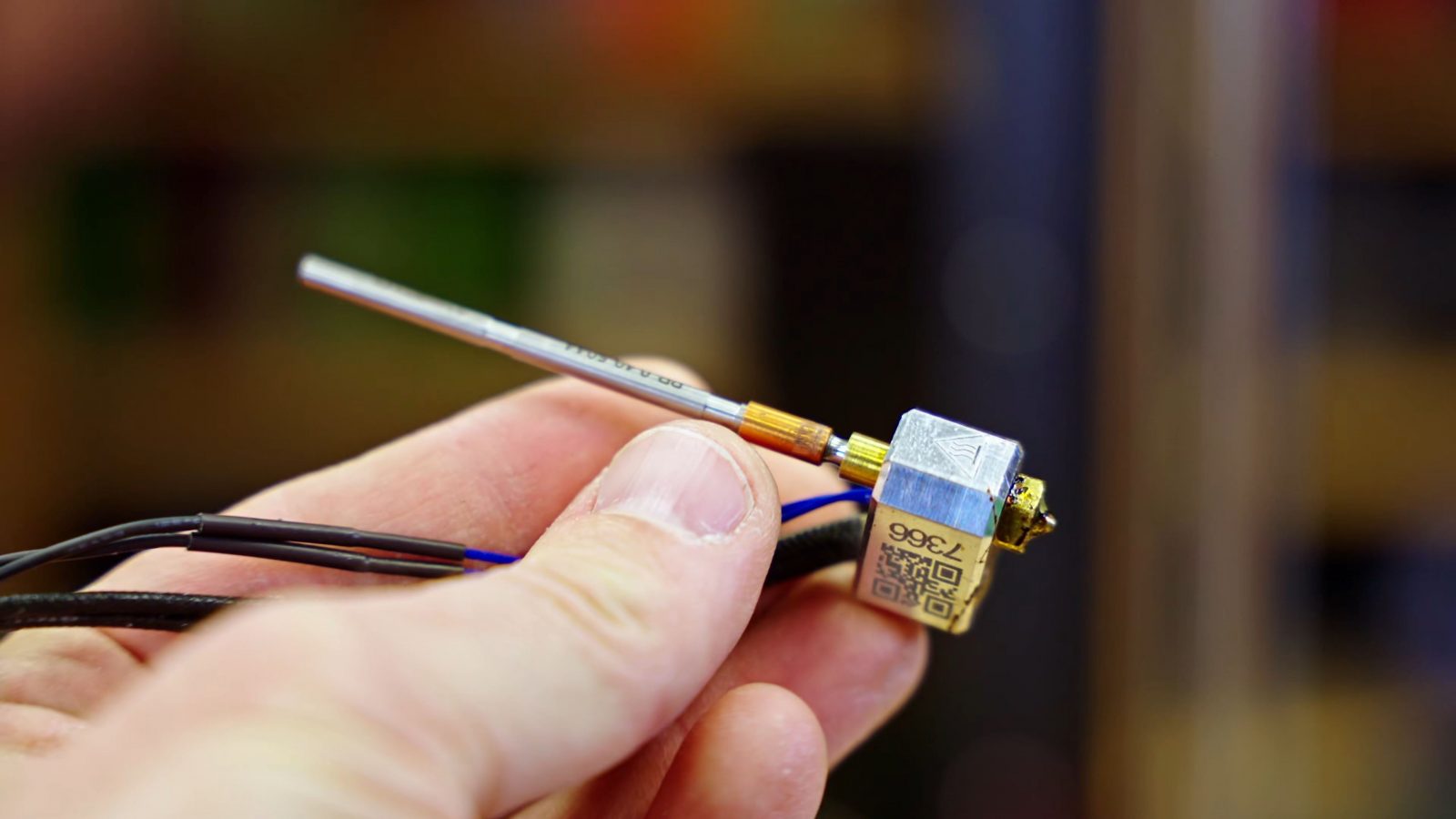

Right at the front you have now got a full graphic color screen. It’s finally being run by a more modern 32-bit ST microprocessor. The hotend gets an upgrade over the v6 and it’s now a new custom leak-proof design, still made by E3D and sharing some design details with Revo, but now you can choose between using quick-swappable nozzlebreaks or an adapter with standard v6-style nozzles. It’s still an all-metal design that isn’t going to eventually fail like Teflon-lined hotends, and it can still print anything from PLA to Polycarbonate. The inductive bed sensor for auto leveling has been replaced by a load cell that directly uses the nozzle to probe the bed, so it gets the bed offset perfectly every time, even if you swap bed sheets or want to print on some thicker, exotic surface. The extruder is an all-new design, the MK4 now has WiFi, better stepper motors, and it still keeps almost all of the features that made the MK3 unique, like those magnetic, PEI-coated beds, power fault resume, built-in diagnostics, and, of course, PrusaSlicer.

And still, in practice, it’s a printer that ends up feeling very familiar, and almost nostalgic. But we are getting ahead of ourselves. Let’s unwrap this one by one, starting with arguably the most important thing about any 3D printer: Print quality.

Print Quality

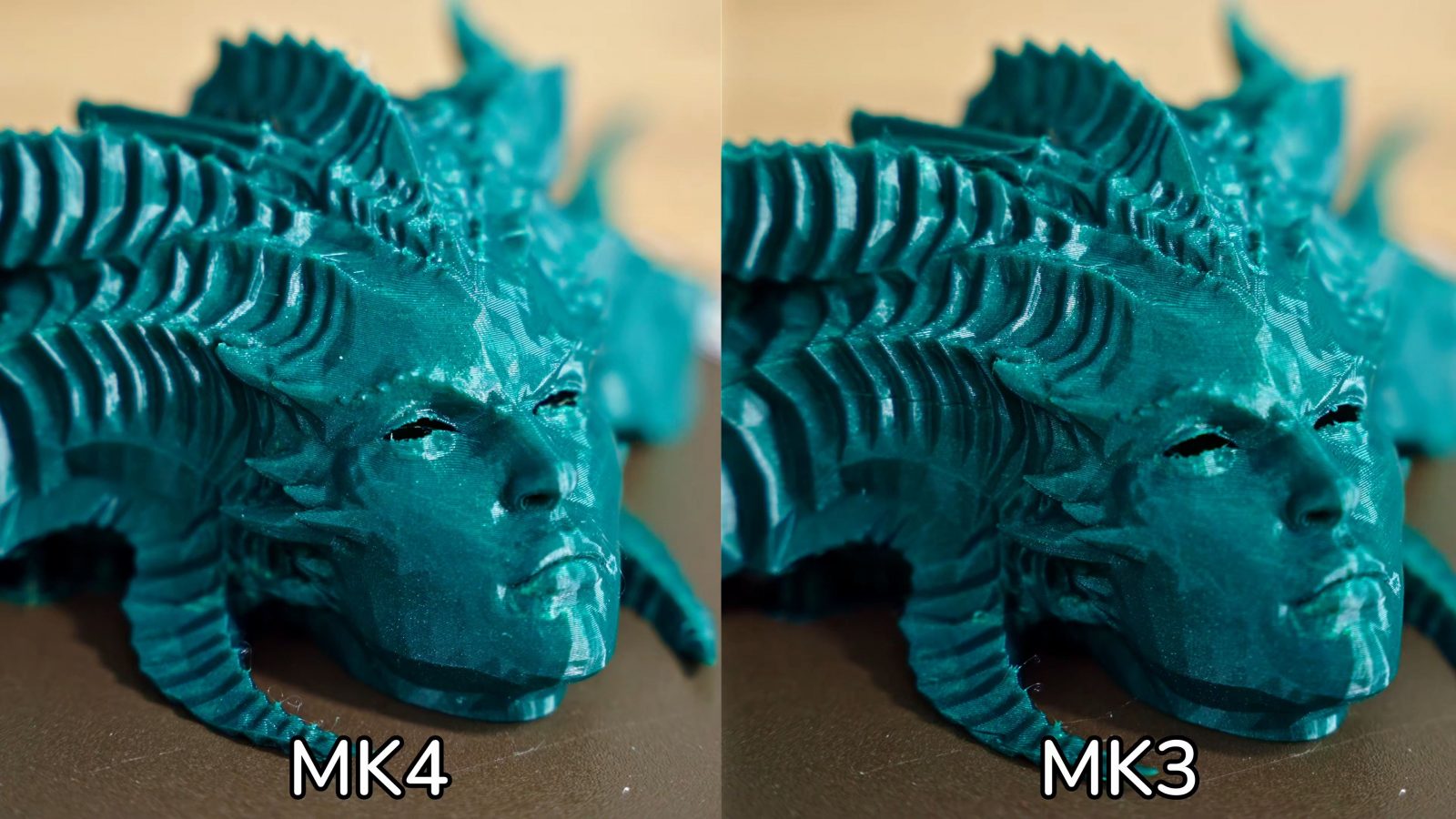

It’s totally fine. Dimensionality has always been spot-on with the Prusa machines and this one is no different, and overall, it maintains the same high level of print quality as we’re used to from the MK3.

The claim is that the new stepper motors have eliminated the VFA artifacts the MK3 was sometimes showing, but that is only partially true. The MK4 now uses 0.9° motors that have twice the physical resolution as your standard 1.8° stepper, but while that seems to have fixed the slight “very fine artifact” wash boarding in some spots, it now shows up in other spots as even higher-frequency artifacts.

Just like edge ringing, this is mostly a cosmetic blemish, but I’m a bit irritated that it’s still showing up even though the new motors were supposed to eliminate it. Now, there was a set of very early MK4s that was built with a faulty batch of motors, so just to make sure, I got in touch with customer support chat, they checked my machine’s serial number and motor lot codes and told me my motors are fine, so I guess this is just how the machine prints out of the box.

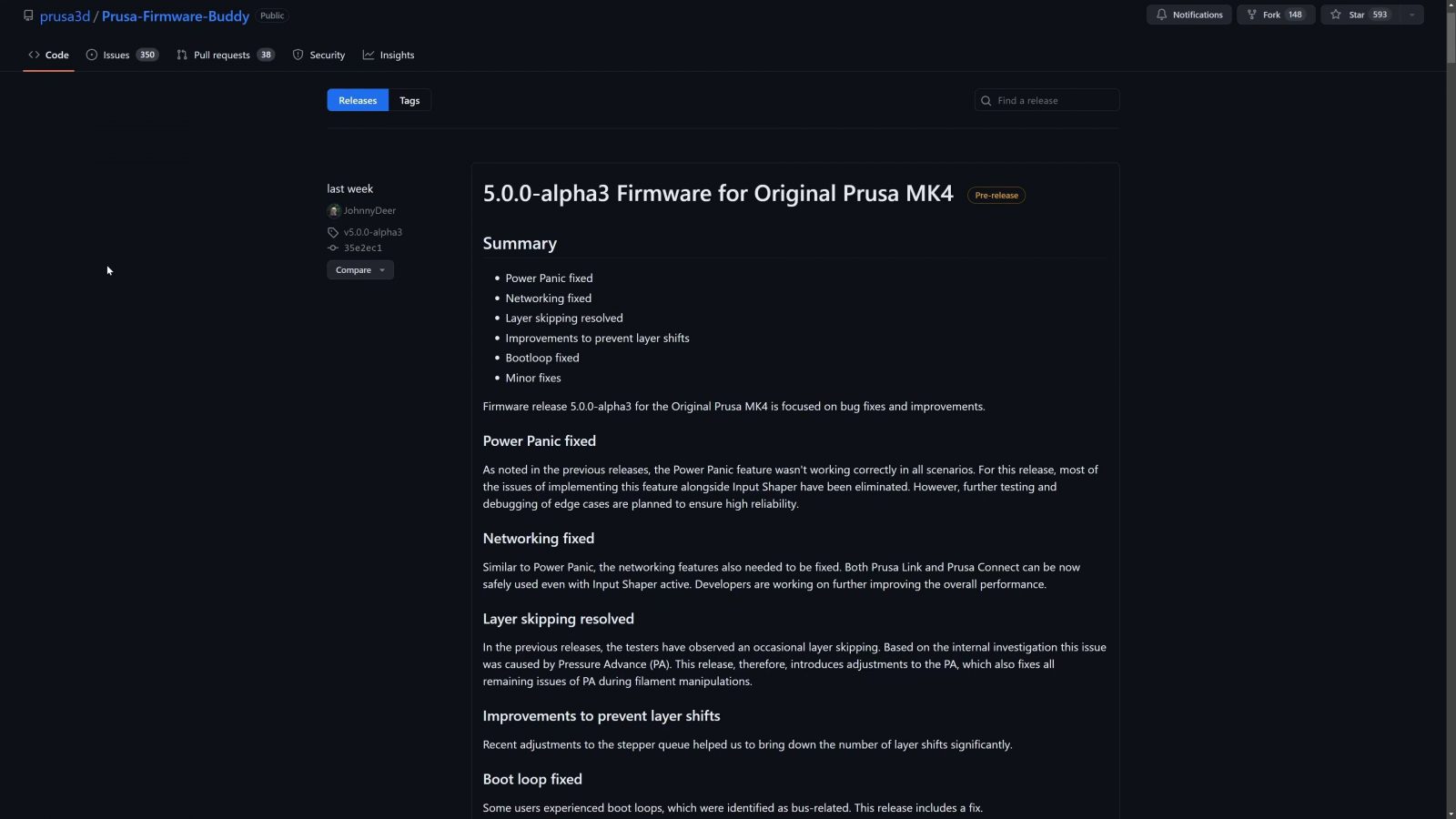

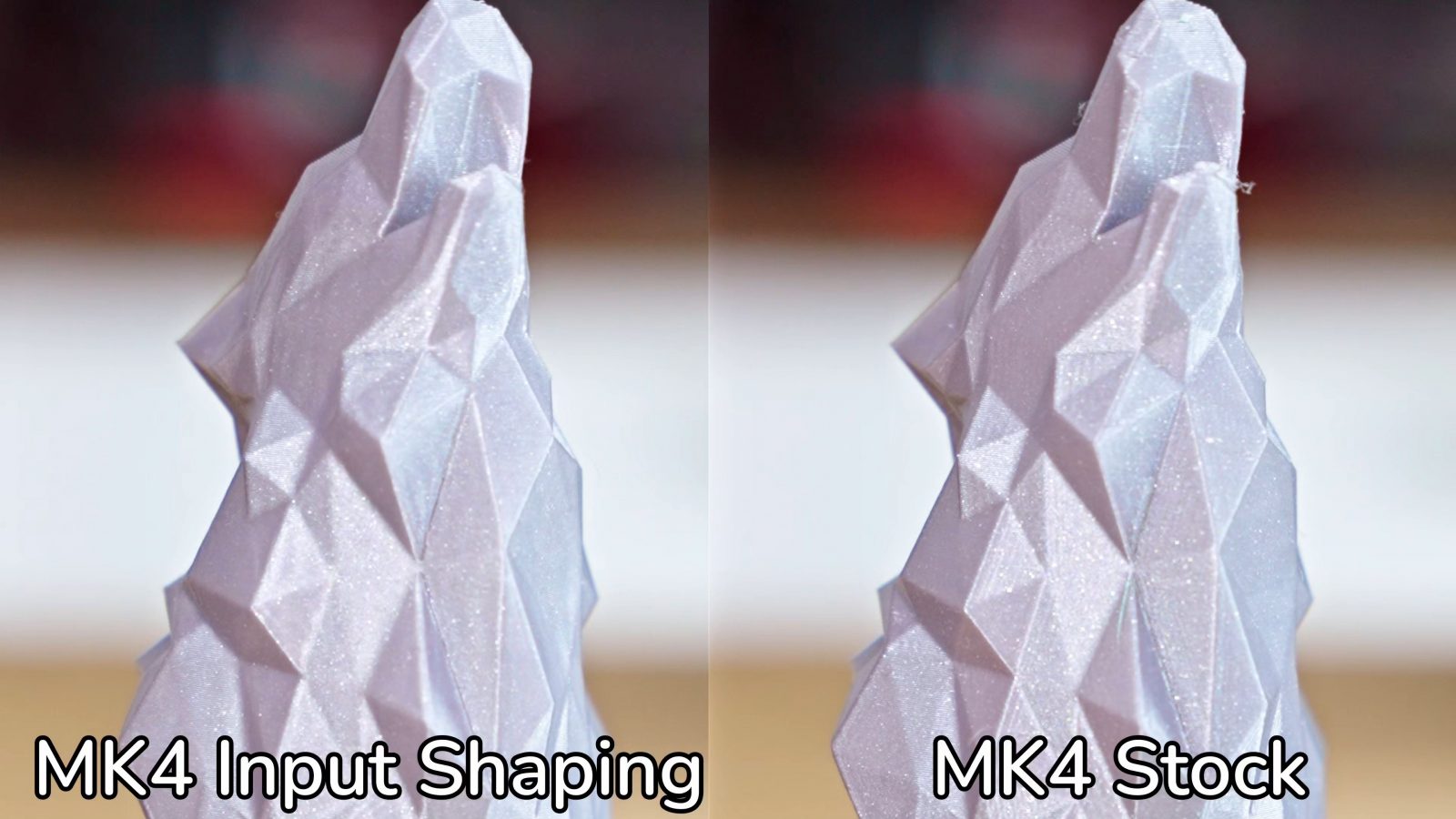

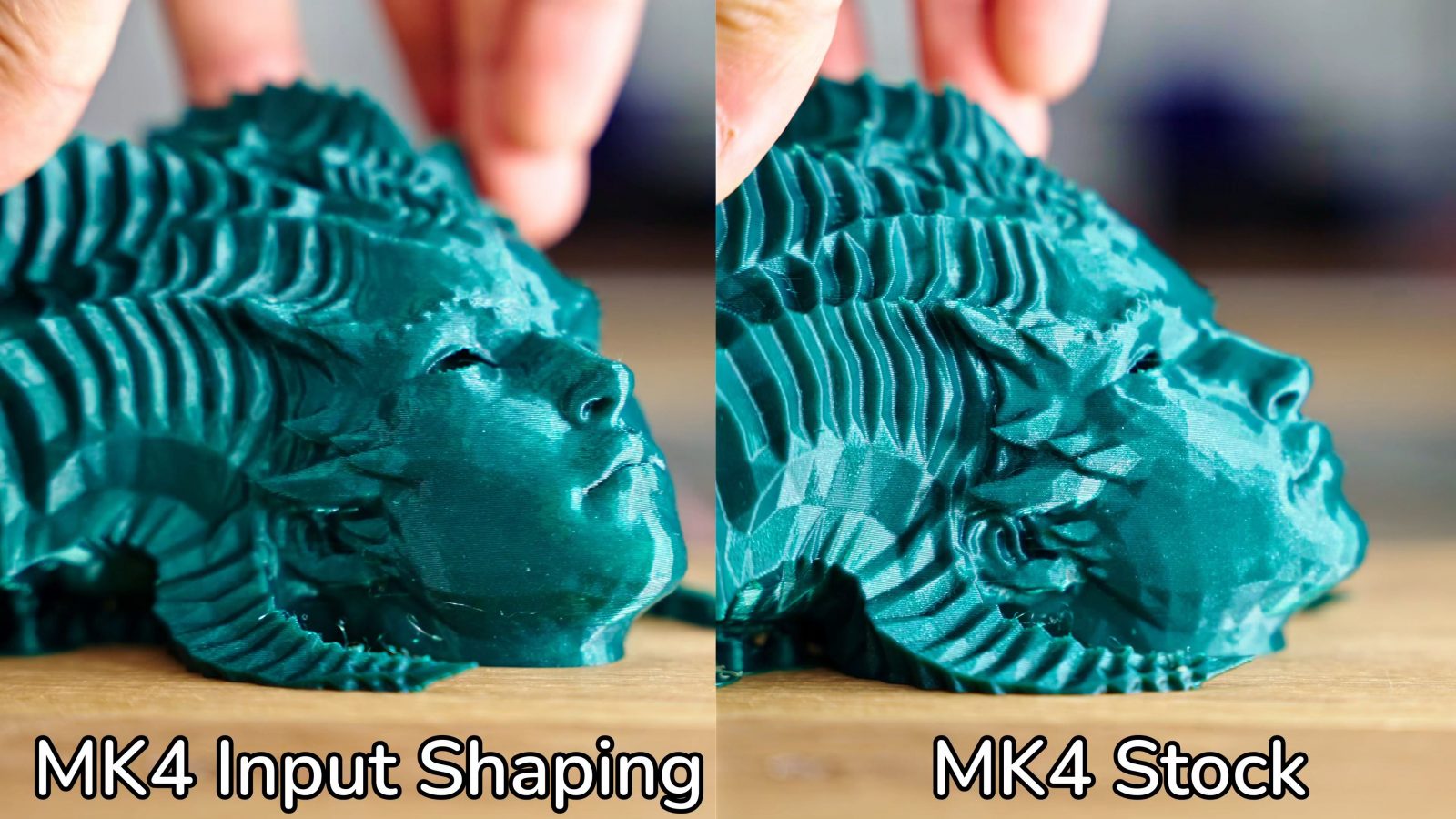

Of course, at the time of me filming this review, you can also opt to switch up that out-of-the-box experience and install the in-development, alpha version of the input shaping firmware. That’s right, the machine’s been out for a couple of months and it’s not even done yet. And I can see why the input shaping firmware is still in alpha: It’s not very good.

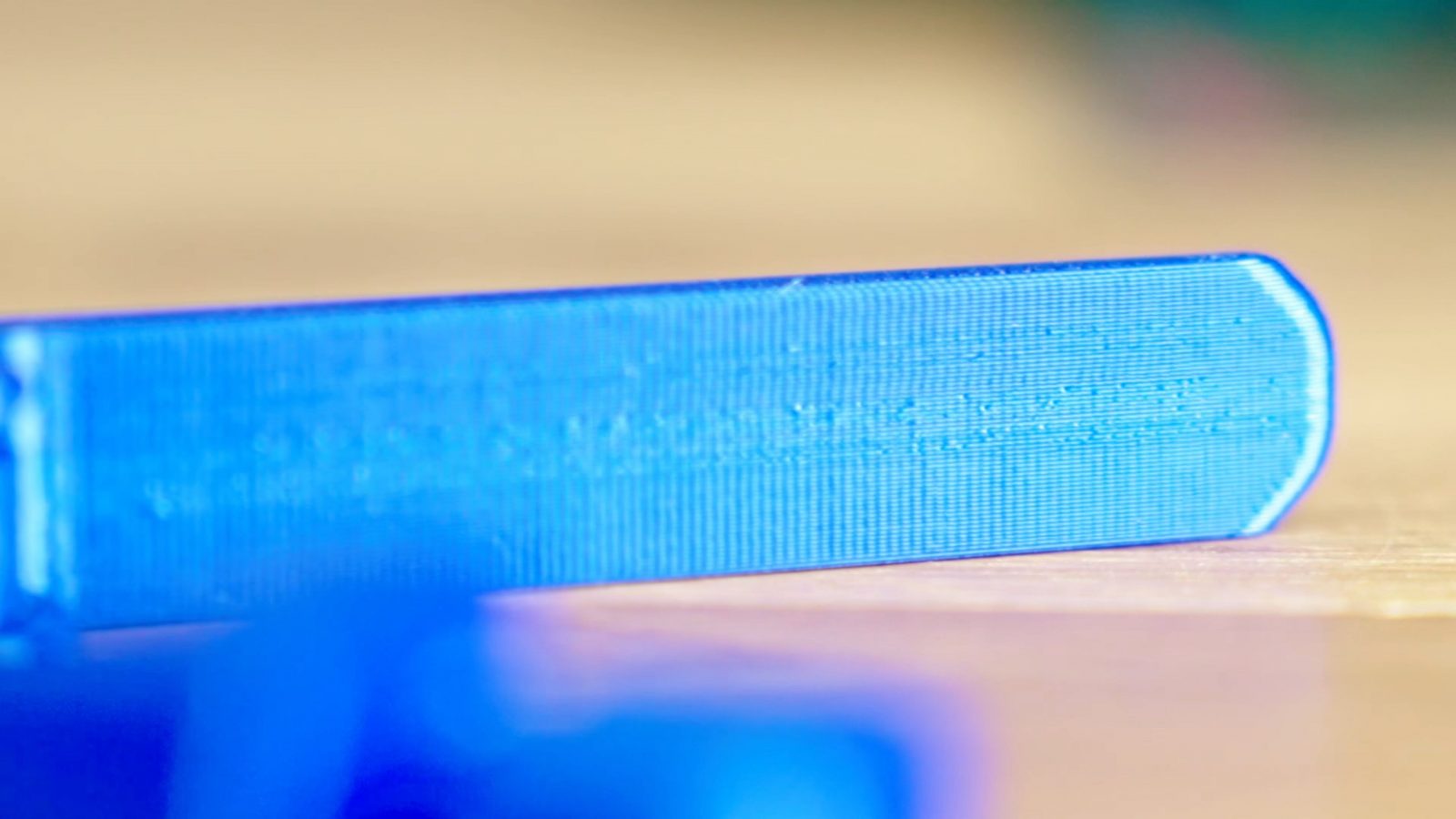

Sure, you get a significant speed boost, and both corner ringing and any sign of the VFA washboarding is completely gone, but you trade it for this lower-frequency warbling and an overall loss of fine detail. Sure, the classic firmware has more ringing, but I find the crisp, slightly ringy stock prints much more pleasing to look at than this.

Input Shaping

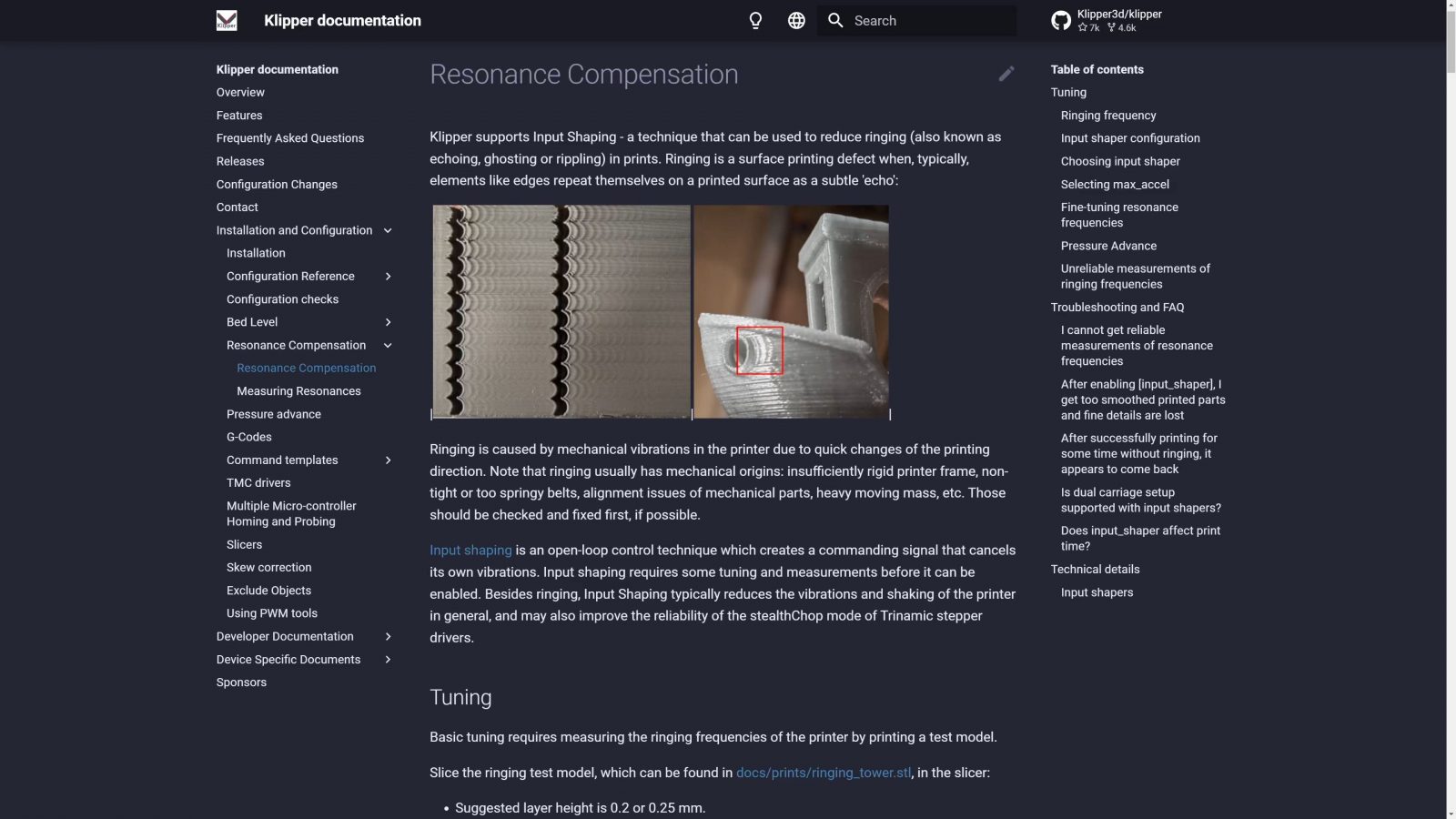

Here is a quick excursion into what input shaping even is.

Basically, it’s a purely software feature that allows the printer to sort of anticipate how the X and Y axes are going to actually move with the inherent mechanical properties of a movement axis, like its motor and belt elasticity, like springiness and damping, and the axis’ weight. Because the machine already knows how an axis should ideally move and it can now also approximate how it’s most likely actually going to move, it can introduce small counter-movements to compensate for a part of that unwanted slop or bounce.

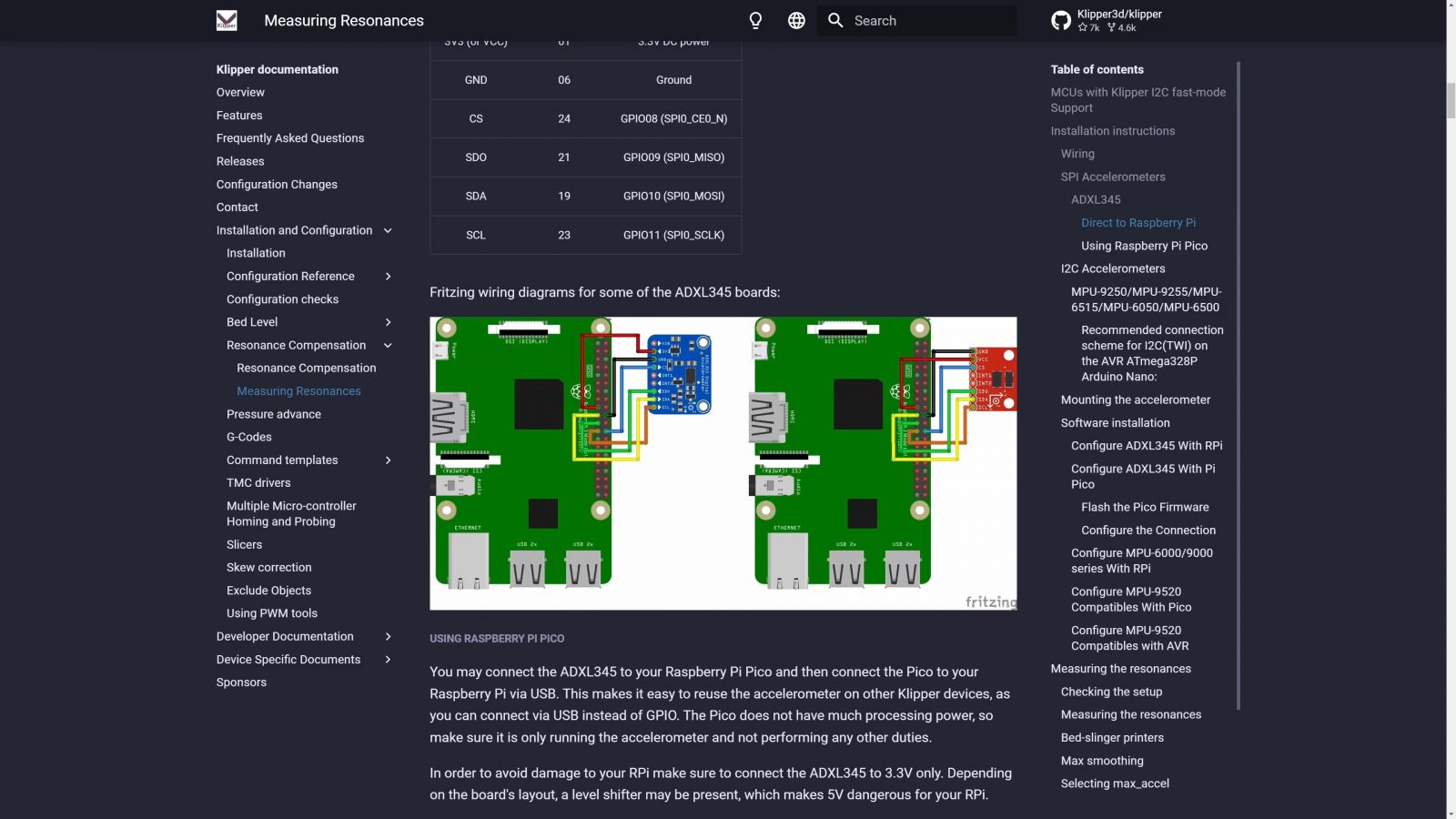

But for this to work, input shaping requires the firmware to know exactly how a specific axis is going to behave, and the standard approach to that is to add an accelerometer to the toolhead so that the printer can measure how that toolhead is going to respond to inputs from the motors. With a moving bed, you would of course need to add one to the toolhead and to the bed. But the MK4 doesn’t have any way to measure the dynamics of its axes. The mainboard does have a connector for an accelerometer, but it doesn’t ship with one and as far as I can tell, the firmware doesn’t currently support it.

Instead, Prusa trusts their consistency with assembled printers so much that they ship one universal pre-made tuning for all printers. And on mine, that tune makes prints turn out arguably worse than without input shaping. This is odd because one of the main points about input shaping on the MK4 was that it wasn’t going to boost print speeds into the realms of a CoreXY machine, but instead focus on improving quality while providing just a little bit of a speed boost, too.

Now, again, this is still a pre-release Alpha preview of input shaping on the MK4, so it’s not finished yet, but… this is a printer that is shipping and that you can buy, and right now, I can only assess what’s already available, so technically, this doesn’t have input shaping yet. Officially.

But if we do want to look into the crystal ball, you know, there are ways to tune input shaping without an accelerometer present – namely sets of test prints the machine could do itself and then you look at the prints and tell the machine which section looked best. Still, an accelerometer would have been way easier. I know this was a concern from the beginning, but I wanted to see how well it would work before jumping to conclusions as it turns out, with this machine and the current pre-release firmware, it very much is a problem.

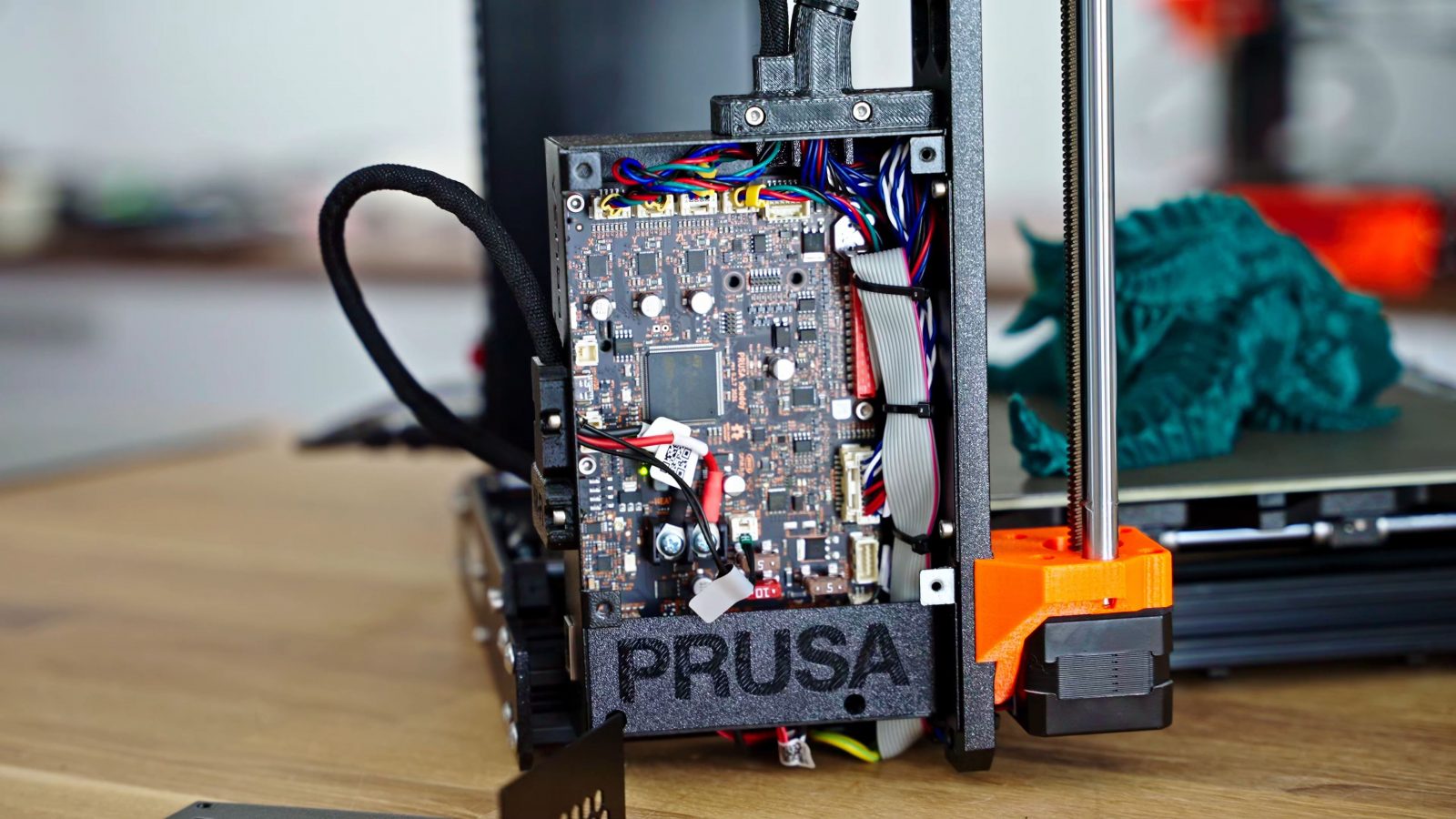

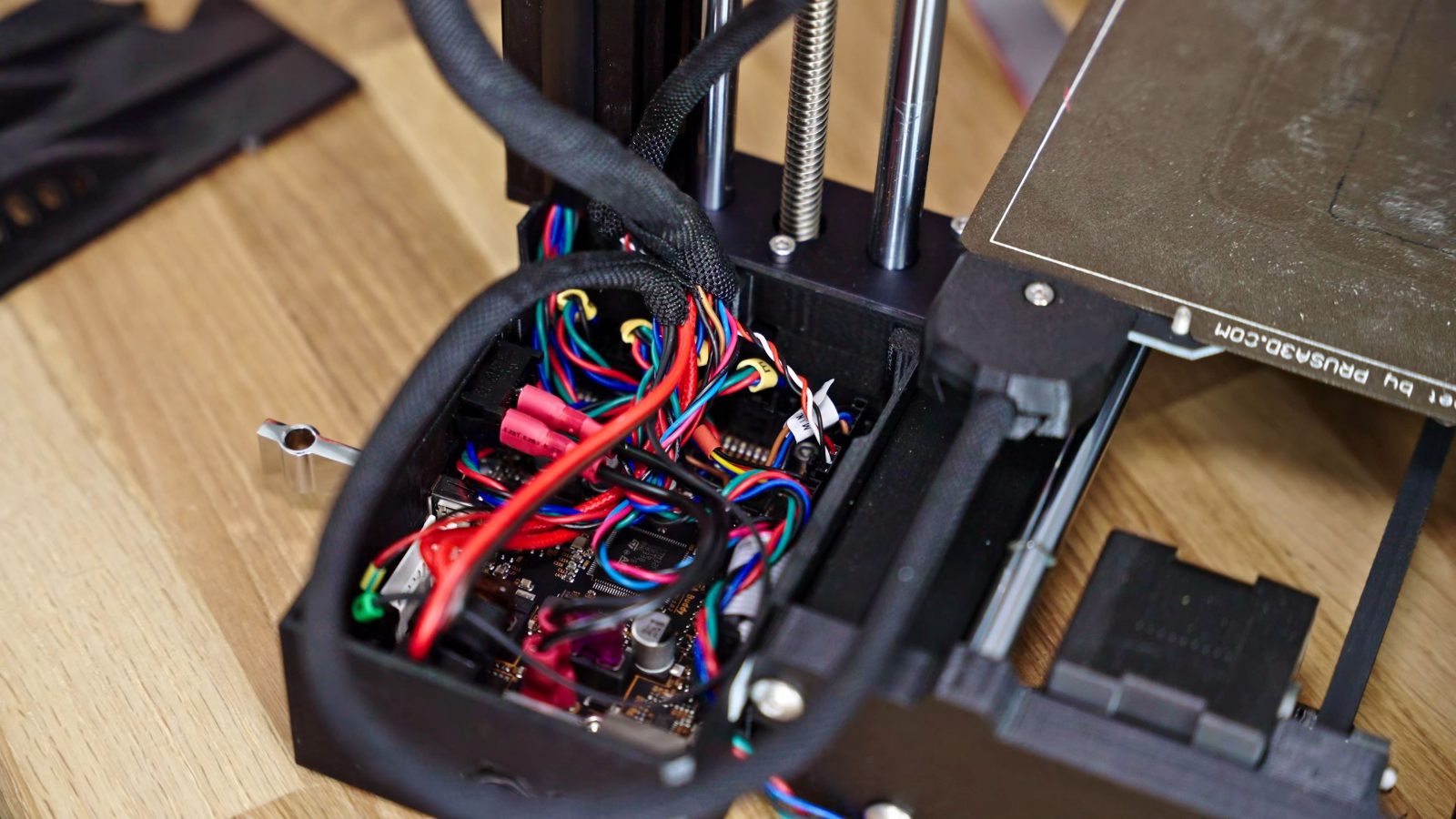

Electronics

The MK4 also runs completely new electronics, and it’s part of their unified hardware platform first introduced with the Mini, and now also used in the XL, printfarm, and of course this MK4. No Raspberry Pi or anything is running in here, the entire printer including input shaping is handled by an STM32, and WiFi is added in with an ESP01 on the back of the machine. The input shaping code, from what I know, is based on Klipper’s code, but of course, without requiring a separate Linux board.

I do appreciate the physical Ethernet port, which tends to be a lot more reliable than WiFi and is also heaps easier to set up – plug in and you’re ready to go. Especially since the WiFi setup on the MK4 is pretty inelegant – typically you just connect to WiFi directly from the machine, or use one-touch WPS, or you connect to the machine’s hotspot with your phone and then set up which network the machine itself should connect to. On the MK4, you instead open the help article with your phone, then tell the MK4 to generate a config file on the USB drive, you take that drive over to a computer, edit the file with your WiFi name and password, and plug it back into the MK4. I mean, it works, but…

The rest of the user interface and user experience feels similar – it’s highly functional and you can tell the folks making this know their way around 3D printers well and the way they’re designing the user interface does have some intent behind it, both are things you can’t take for granted. Though both the display on the machine and PrusaSlicer on the desktop have that distinct brutalist Panelák Style – it gets you exactly what you want very effectively, but it definitely does not have that Apple-esque smoothness to it. The screen on the printer is a touchscreen, you can enable a touch-based interface if you prefer, but I like the physical click wheel and since the UI is built with the physical input in mind, it works well.

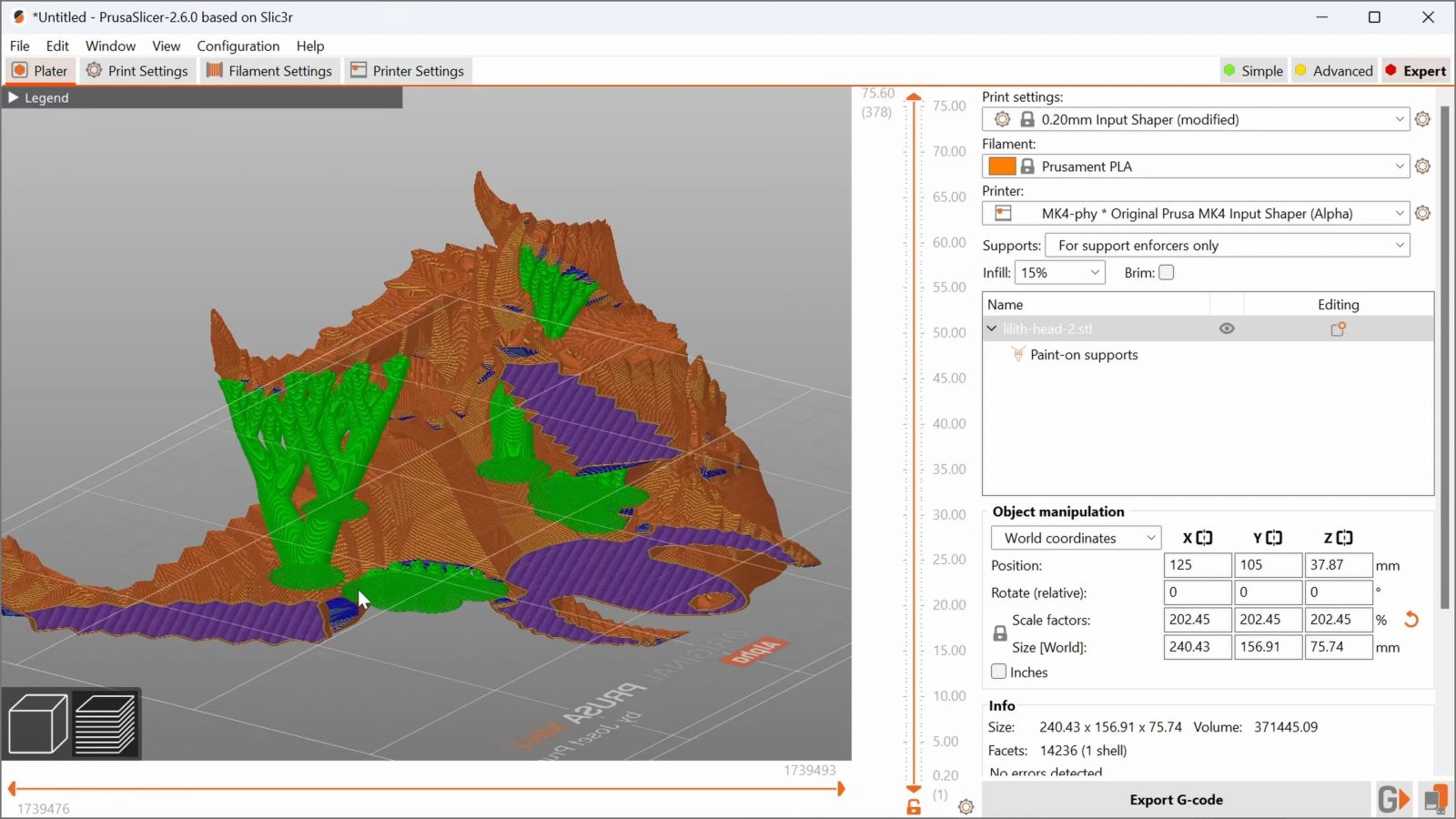

PrusaSlicer

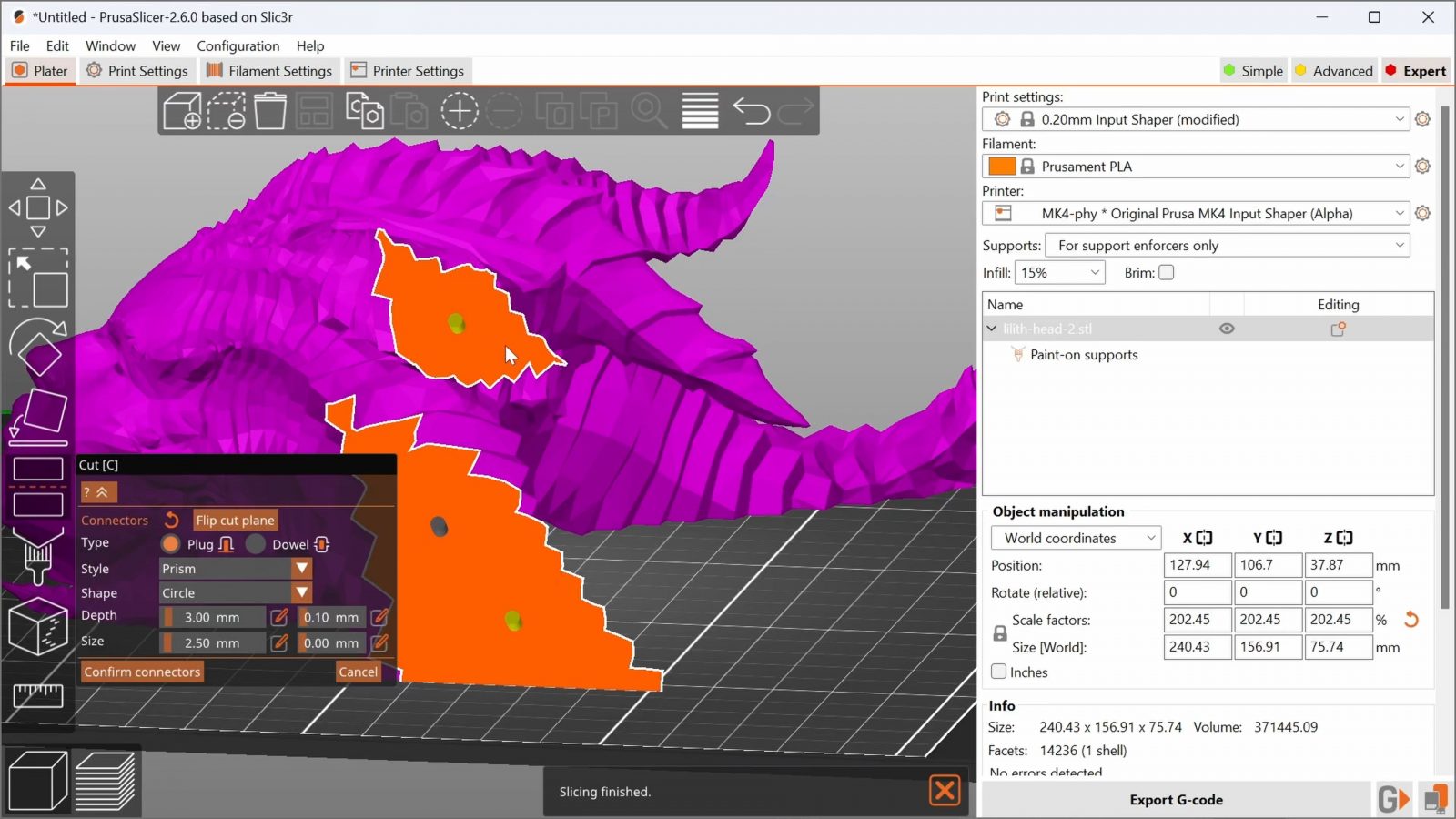

Speaking of PrusaSlicer, it is incredibly good. I’ve already made a video about the changes the current 2.6 version introduced, and as I have always said, aside from the printer itself functioning, the slicer will make the biggest difference in how much you are going to enjoy using any particular 3D printer

Because PrusaSlicer is open source, you now get the exact same PrusaSlicer experience with an Anycubic Research or Bambu Labs machine, too.

Instead of publishing as open source, Prusa could have spent their time on developing a closed-source UI that would at first still use the open-source Slic3r core in the background, and then eventually replace that too with something proprietary, so that they would have their own locked-down software suite. Instead, they decided to keep publishing as open-source and to keep adding to open-source projects, which is laudable but ultimately means that in the current market, PrusaSlicer just isn’t a distinguishing factor anymore because every manufacturer can and is using it. Again, great for users, but not so great for making the MK4 more desirable than the alternatives. My full thoughts on that in the last video.

PrusaLink and PrusaConnect

Moving on, there is also PrusaLink and PrusaConnect now.

Link is the network-local option that runs on the machine itself, which is great because it does not depend on anyone else’s servers staying online for it to function. Of course, you can only connect to it as long as you are on the same network, and it gives you a separate web interface for every machine if you have more than one. If you want a consolidated print farm web interface, then PrusaConnect is the cloud solution for that. I have briefly tried both, but I think what you will end up using most is PrusaLink with the option to send files to the MK4 directly from PrusaSlicer. That is just the most convenient feature, but of course, aside from temperatures and print progress, the MK4 lacks the option to actually check in and see your prints remotely. There is no webcam on the MK4 yet, but there are talks about eventually supporting an ESP camera module, for the time being though, you can hook up an old phone and use that as an integrated webcam in the web interface.

What is special about the MK4?

Now, with the Prusa machines, what makes them unique and even worth looking at at all, is not the headlining features, because let’s face it, the things that are new about the MK4 vs the MK3 are not never-before-seen things.

Instead, and this is something that the MK4 still does very well is that the stuff that is there, usually is pretty well thought out and the way it’s being done is ultimately well iterated and fine-tuned, and that’s hard to formulate into a review or advertise as a feature on a product webpage. Sure, there is also stuff that you can list out, like the carried-over Trinamic drivers, flexible, magnetic, PEI powder-coated print beds, which now come with even more surface options, a filament sensor, built-in diagnostics, crash detection, though not with input shaping, power fault resume, a good slicer, those are all things that add to the overall experience.

But the rest of the market is catching up very quickly and I’m not sure if 1200€ is still justifiable for this machine. Especially considering that looking at the comments under these videos, people don’t seem to care much for things like sustainability, where Prusa publishes an audit report for their machines and the fact that it’s made and developed locally here in the EU, which does add to the cost.

With the way the MK4 is specced, it does have its applications where it’s going to be a perfect fit, and for me, because I already have it, it’s probably going to become my main workhorse, too. As with basically any review on the internet these days, yes, this machine was provided free of charge, but I have never and will never allow payment or editorial input from manufacturers for these reviews. Otherwise, it’s just not a review.

But, would I personally buy a MK4 at this point? Probably not. With a lot of things, I’m a bit of a cheapskate and I would probably get some sort of Ender, Sovol, or Elegoo machine, throw some core upgrades on there, like a proper hotend, and just deal with whatever little issues or annoyances that machine might then have in the long run. Yes, I would occasionally get annoyed with it, probably, but I think that would be bearable for having spent a third of the money upfront.

For situations where you have to have a machine that just keeps on working, the MK4 or honestly, even still the MK3 can and does make sense, but that’s the sort of buyer who would also consider spending for an Ultimaker, but for DIY tinkerers like me or probably you as you are watching this video, the MK4 just doesn’t seem to provide the oomph, the excitement, the bragging rights, that you would expect to get at this price point in 2023. Two years ago, this would have been an absolute baller machine, today, it’s still conventionally good, but only conventionally good just isn’t that special anymore.

So, I hope they figure out input shaping on the MK4. If you have a MK4 and you have tried the alpha firmware, please leave a comment under my video with how well it’s worked out for you.

As always, thank you to my supporters on Patreon and YouTube memberships who make it possible for me to do this, to everyone, thank you for watching, keep on making.

Models shown:

Ergonomic lockable bit screw driver with print-in-place freewheel by HD_Creator

Flexible Hexagonal NASA Chainmail Tie 3 sizes by Maker81

Articulated Whale Shark by JD3D

Vise Grip Print in Place by Adam Cook

Official Diablo IV Lilith Head by prash.makes

Low Poly Howling Wolf 2.0 (Decoration)(No Supports!) FIXED by Brett Poultney

Check out the Meltzone podcast with Tom, Stefan and Scott Lahteine on How open source works

💙 Enjoying the videos? Support my work on Patreon!

Product links are affiliate links – I may earn a commission on qualifying purchases (at no extra cost to you)

Check out my second channel “More Layers” on YouTube for livestreams