When the MK3 came out about five years ago now, it was an easy recommendation in a sea of then-mediocre alternatives that took years to catch up. Now the tables have turned, and it’s on Prusa’s machines to catch up. Is the classic Prusa recipe still enough to make the MK4 worth 1200€? I’m not convinced yet, so let’s explore. Even though they’ve dropped the “Prusa Mendel i3” part of the name, the MK4 still is a continuation of the “Mendel” heritage of Prusa’s printers, and as such, the basicContinue reading

Author: tom

Open Source isn’t sustainable anymore

Brothers. Sisters. I want to apologize. For years you have put your trust in me and for years I have led you astray. Not by evil intent, but by misguided conviction. And for that, I am sorry. I believed open source and the free sharing of information would bring upon a new age. A new age of innovation, creativity and community. And, with a hopeful heart, I preached its benefits to you and reprimanded those who would twist the spirit of free and libre development. But I could not succeed.Continue reading

Testing E3D’s new Revo High Flow nozzle to its limits!

The E3D Revo High Flow nozzle is sort of a solution to a problem that E3D created themselves. It’s typically what Apple would do, but this isn’t in fact a bad ecosystem or a bad product, but the core issue with these is, of course, the Revo ecosystem uses nozzles that are all the exact same length, which makes for super easy quick swapping. You take out one nozzle size, you pop in another one, you don’t have to reset your Z height, there’s no extra mass, extra PID valuesContinue reading

Why you should get a 3D printer NOW

On this channel, I talk a lot about 3D printers and 3D printing and making stuff that uses 3D printing, but chances are, you’re watching this and you DON´T have a 3D printer of your own. Well, should you get one? This video is the companion video to why you should NOT get one, so let’s get started on this one with 5 reasons why you should consider getting one. Reason number one, and this is obvious: A 3D printer is a tool, and an incredibly versatile one at it,Continue reading

Why you should NOT get a 3D printer

So you’re considering getting a 3D printer? Well, before I get you too excited with my other video about why you should get one, maybe first consider this video about why you should not get one. There are quite a few things that only become apparent once you’re in deep, and I’ve been in deep for the last decade. So here are five aspects to factor into your decision on whether you should get a 3D printer for yourself or even recommend getting one to a friend. Consideration number one:Continue reading

Free CAD

Are you tired as well, that seemingly the entire CAD landscape consists of extortionary licensing models that lure you into learning their tool for free and then slamming you with a massive subscription fee as soon as you’re hooked and start using it more? Or software that regularly removes features that you’ve grown to love? Well, worry no more, because there is an alternative, actually more than one, but for this video, I wanted to take another look at FreeCAD, a free and open-source, fully-featured CAD tool that is aContinue reading

Prusa Slicer 2.6

It’s a new year, it’s a new PrusaSlicer release. This one is 2.6, alpha 3 at this time at the time of me recording, and it brings with it some features that, each one on their own, are just, nice, but when you put them all together, it makes for an overall well-improved package. Of course, this isn’t just for Prusa machines, you can use PrusaSlicer with any 3D printer that speaks gcode, in fact, the 2.6 release now out-of-the-box has tuned profiles for the new Elegoo Neptune series, CrealityContinue reading

Bambu Lab’s P1P First Look

Yeah, it’s pretty fast! This is Bambu Lab’s P1P, and it’s basically one of their “prime” X1C printers with a lot of the parts just stripped away that you don’t really need for running the printer – and then some. This one clocks in at 784€ including tax, and while it is an incredibly impressive printer, especially at the price point, it’s sort of a weird mix of decisions between keeping high-end features from the X1C, stripping away others that honestly wouldn’t impact costs much, but then including some upgradedContinue reading

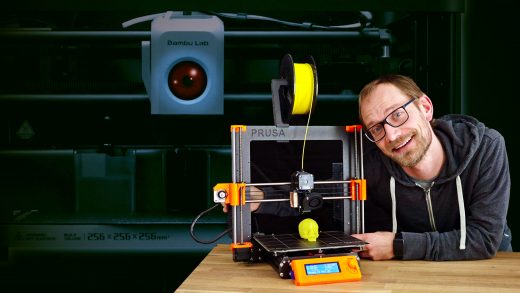

This printer is OLD. Why is it still my favorite?

This is my Prusa. There are many like it, but this one is mine. Actually, this one is exactly like all the other ones out there, except that I put an E3D Revo in it because I needed to review that hotend platform and it’s using a newer official model of the fan shroud because I melted off the one it came with at some point. But it’s still the printer I actually use whenever I just need to print stuff. This one, on the other hand, has seen someContinue reading