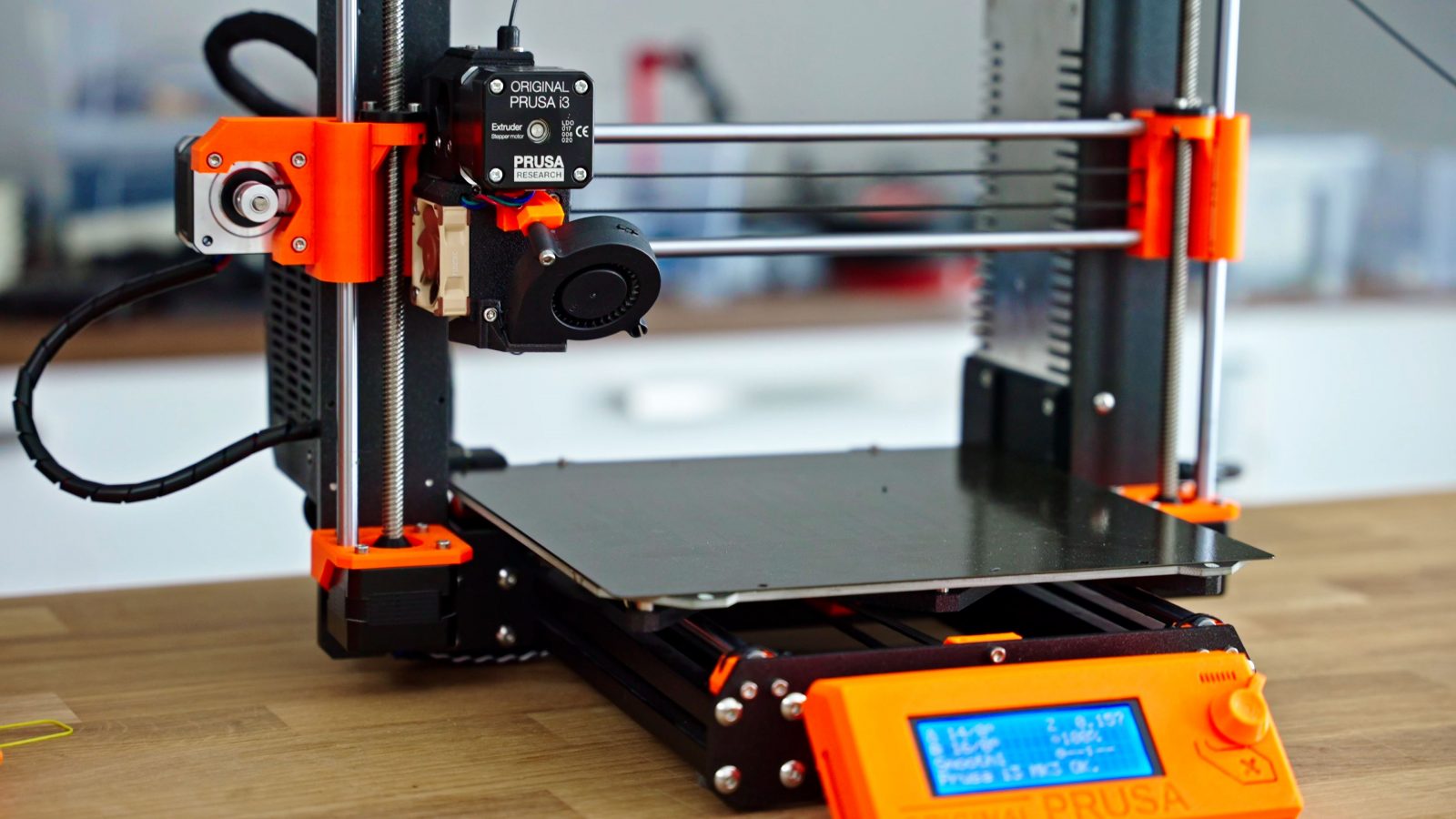

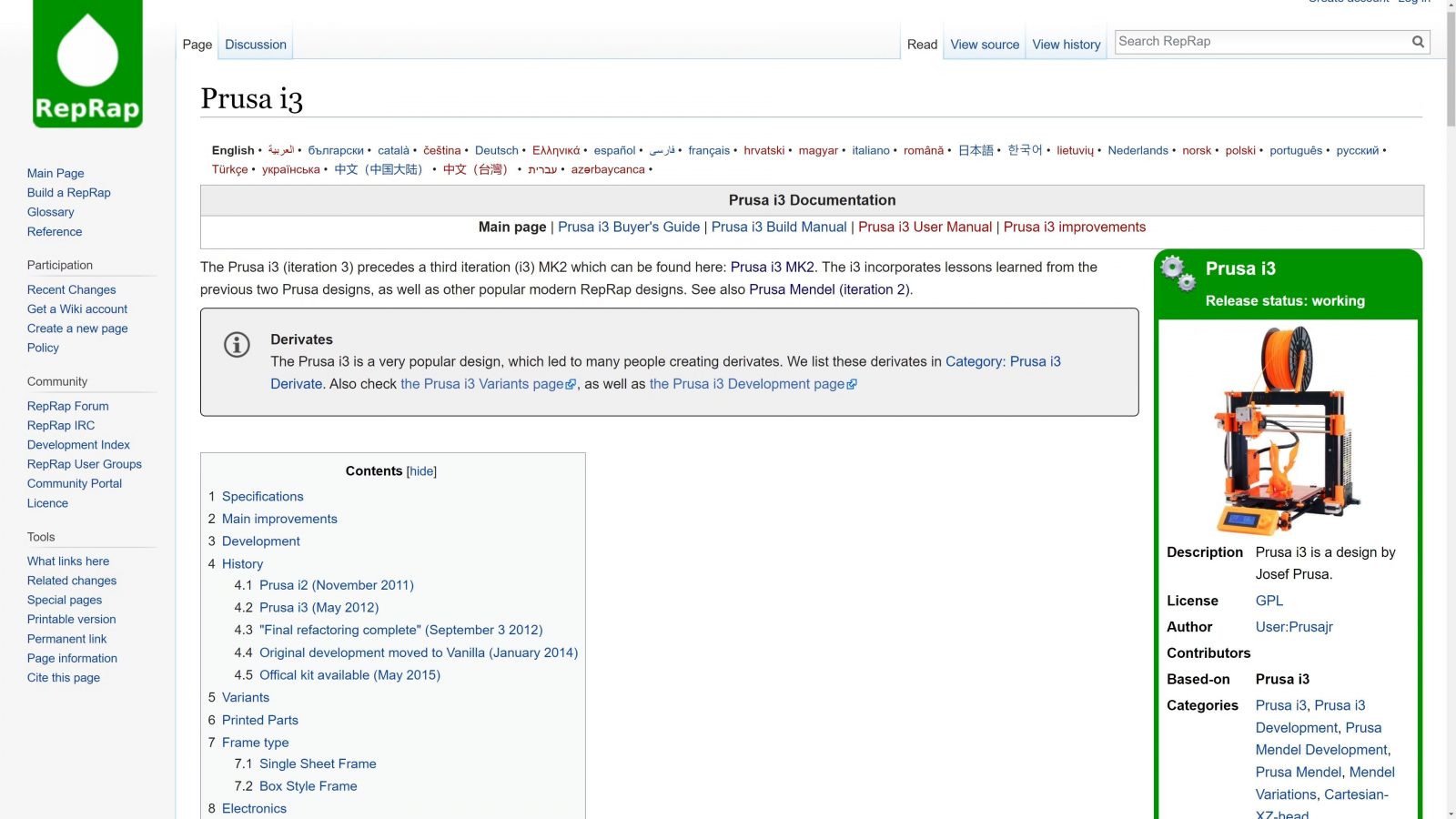

This is my Prusa. There are many like it, but this one is mine. Actually, this one is exactly like all the other ones out there, except that I put an E3D Revo in it because I needed to review that hotend platform and it’s using a newer official model of the fan shroud because I melted off the one it came with at some point. But it’s still the printer I actually use whenever I just need to print stuff.

This one, on the other hand, has seen some stuff, so we’re going to give it the TLC it has earned, but I also want to explain why I still prefer using this now five-year-old design over any of my newer printers that are honestly capable of printing parts every bit as good, if not better, than the Prusa, and what manufacturers would need to do to win me over.

So, yes, this is, by today’s standards, an ancient printer. At the same time that Prusa only released the tweaked MK3S and MK3S+ machines that are still mostly identical to the original MK3, someone like Creality has put out over a dozen brand new machines, “each one better than the last”. That’s sarcasm if you haven’t noticed already.

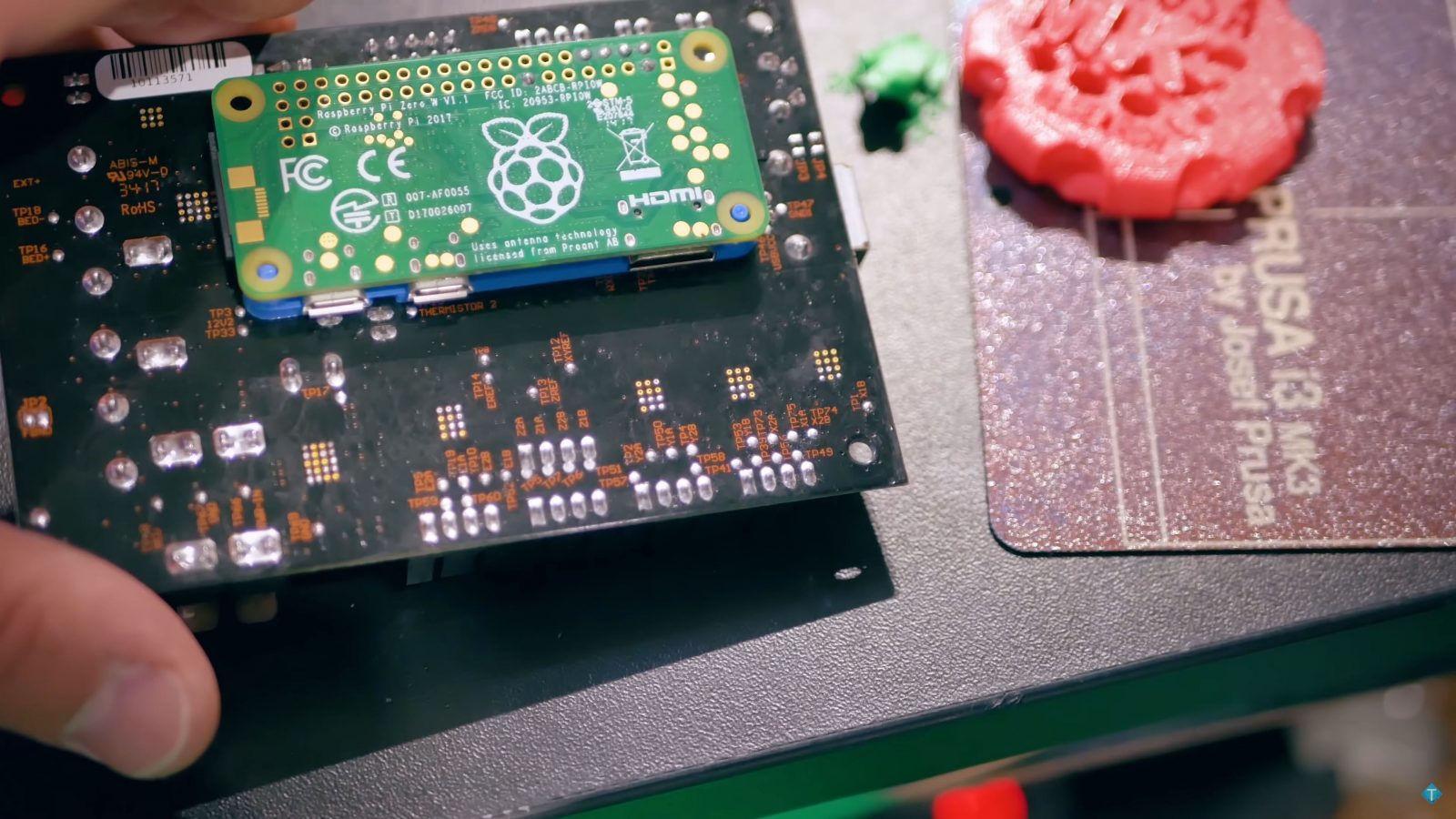

But yeah, the MK3 series is objectively lacking some of the features that other machines have, like networking and remote monitoring, that Raspberry Pi Zero header for OctoPrint in the MK3 never took off, an enclosed build space, faster speeds that are achieved with input shaping, those things I actually do miss and other off-the-shelf printers are more recently now starting to ship with those features as default. On the other hand, the very visible stuff like the monochromatic, text-based LCD, or the headlining 8-bit MCU essentially from the 90s, honestly don’t bother me that much.

Because on most machines that tout a 32-bit MCU, it’s really just a cost-saving measure, the more modern MCUs are just cheaper. They’re not doing anything with the extra horsepower though, and when they’re running new buggy firmware on a 32-bit chip vs the endlessly tweaked version of Marlin that runs on these, well, then these are going to make for a better experience overall. Unless you’re doing real-time input shaping, these are plenty fast enough to run a 3D printer.

The screen and the machine’s build probably feel the most dated – but they work. There’s no reason for injection-molded and folded sheet metal parts everywhere, and the screen is really not something you ever have to interact with much. Load and unload filament, start prints, that’s really it. It’s not nice, it doesn’t look slick, but it fits in with the overall sort of DIY aesthetic and for me, this just isn’t a drawback in actually daily using the machine.

And frankly, out of the machines that I own, this is the one that is the nicest to use in practice – and that is a huge factor for me. I have a ton of machines that I test, and I don’t have the time to tweak and upgrade and fine-tune each and every single one, otherwise, this channel would be entirely about Ender-3 upgrades, which, looking at how much interest there is in those kinds of videos, wouldn’t actually be a bad direction for the channel. But I don’t want to do that, I want to explore more than just that one cheap printer, so when I try and test a new machine, I use them just as god intended, in that case, with the manufacturer’s profiles and recommendations, but otherwise, I just want something that reliably works. It’s the same thing that phone reviewers come to in their conclusions when they had some fun with the newest Oneplus 12 Pro Ultra and they think it’s pretty okay, but ultimately their SIM card goes straight back into their Pixel 5 for daily use.

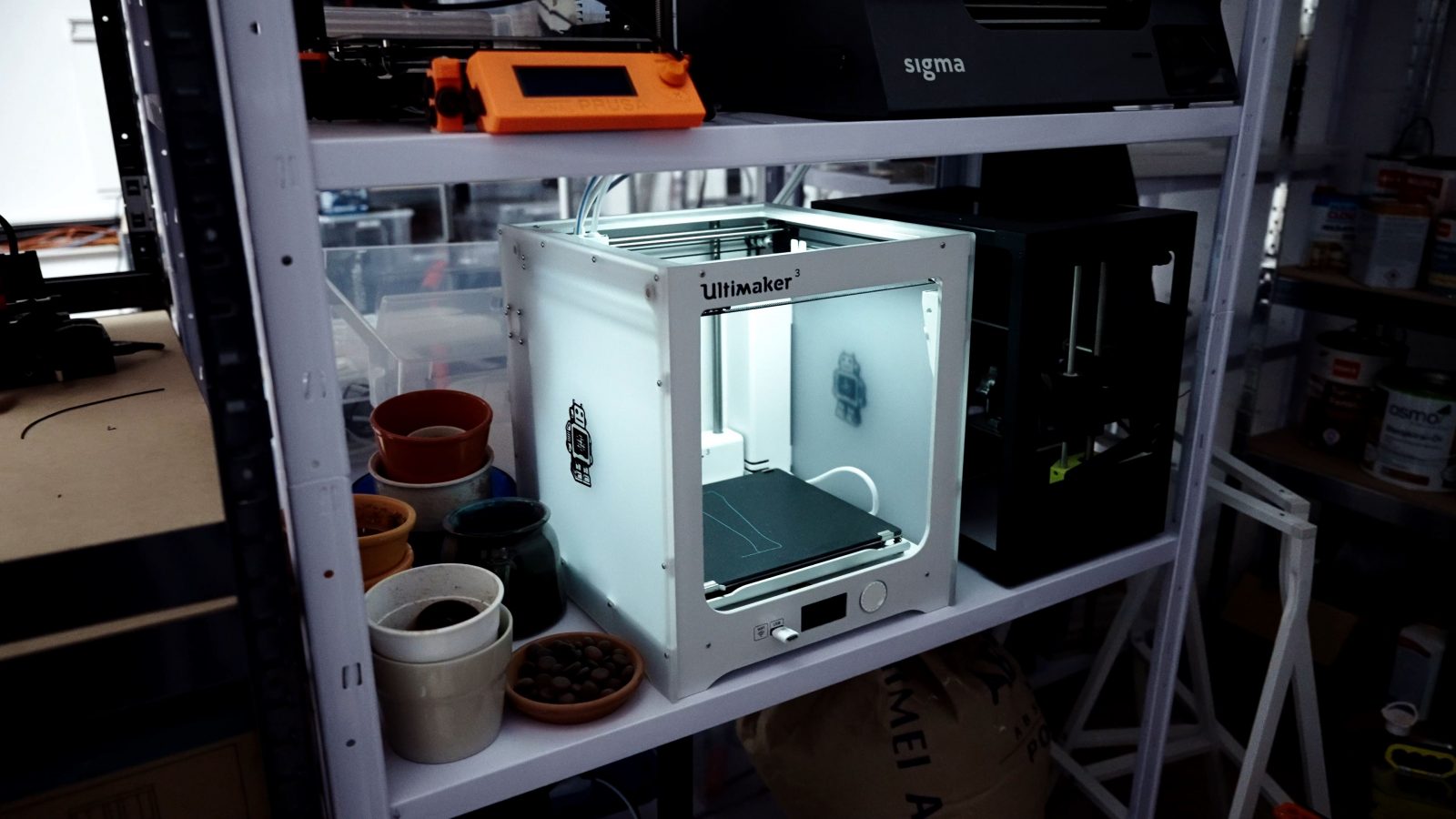

My Ultimaker 3 has been sitting on the shelf after its 5th jam within a single spool of filament, which was the point that I got sick of cleaning out the nozzles. My CR-30 would be super cool for automated printing, but getting parts to stick to the belt has been an absolute pain. And other printers which I actually genuinely liked, like the Ender-3 v2 or the Neptune 2, they’re not an upgrade over ye old Prusa when it comes to how easy and convenient it is to use them overall.

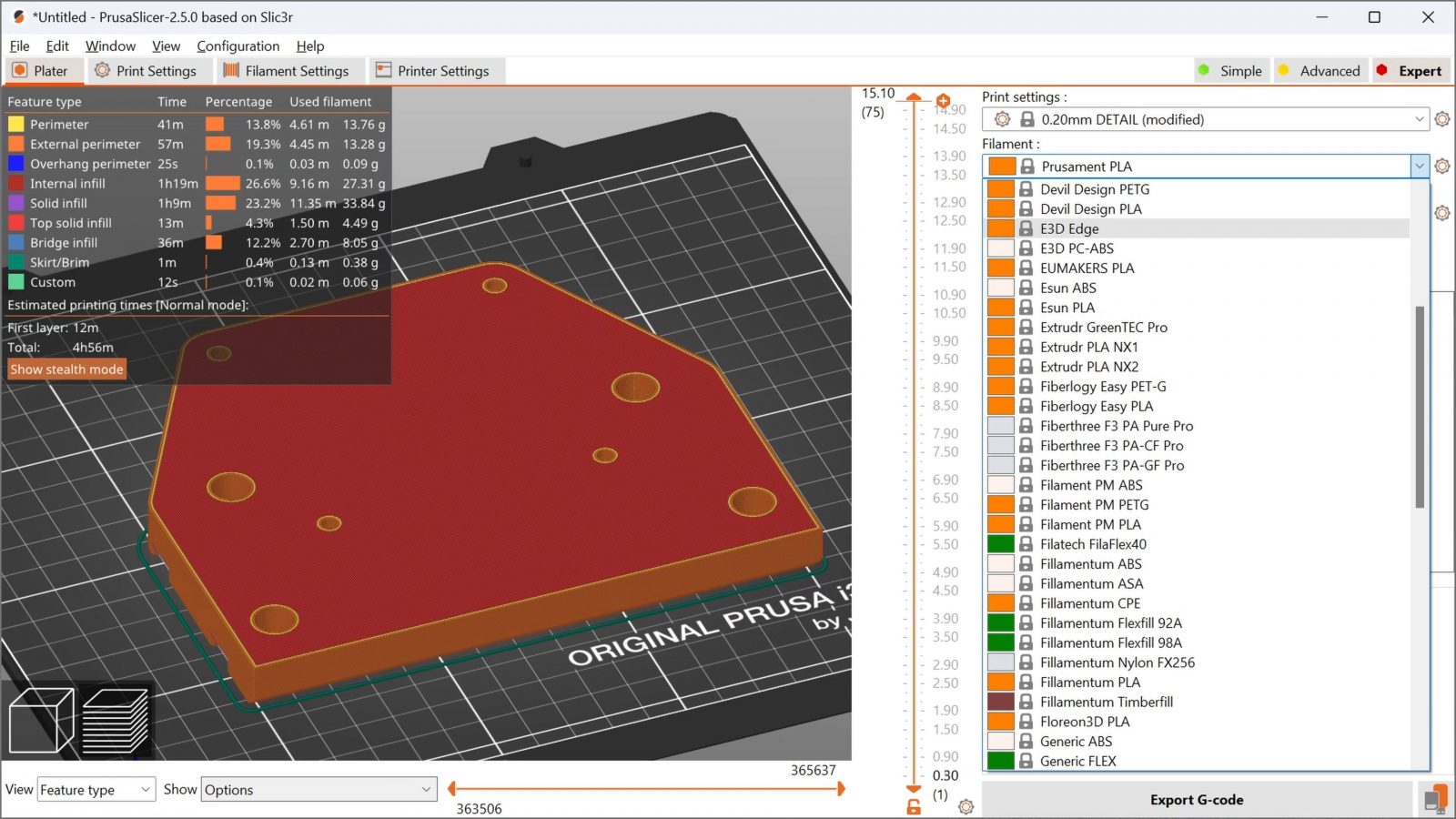

That boils down to the slicer that comes with heaps of profiles that are perfectly tuned to the printer, everything working together as a unit, but also auto-bed leveling and auto-squaring coming as standard on the Prusas, and the PEI flex plates being more thermally stable and so much easier to use vs having to chisel off parts from the glass beds on the more budget-oriented printers. It adds up to more than the sum of its components.

But then why don’t I use a Bambu Labs machine or an AnkerMake M5, which are printers that come with those features and then some? Well, I don’t have either of those. Anker often are very strict when it comes to what the reviewers they work with are allowed to say, and Bambu Labs are just not an established enough company yet that I felt confident to jump onto their very first printer and the hype that followed it. I mean, Kickstarter is a contentious topic to start with. They’re just getting started and have just barely shipped the Kickstarter rewards, so I have no clue what sort of company they’ll end up being. That being said, there is a P1P on its way to me. Bambu Labs are doing a lot of things that I’d agree with – they’re using PrusaSlicer as their software, even if they have to be firmly poked to adhere to the open-source licenses, at the very least they seem to be great when it comes to encouraging honest reviews of their printers. Where I think so far they actually already beat out many other manufacturers, is that you can get spare parts for their machines if you ever need them without having to rely on questionable sources from Aliexpress, where quality is a gamble at best. Instead, you can just get all the parts you might break outside of warranty straight from them at, honestly, super reasonable prices. Which implies that they’re not designing the machines to be thrown out every two years for you just to buy the “v2” or Pro model as the old one disintegrates.

So speaking of replacement parts, I think it’s time to get this sad MK3 fixed up and then have a bit of a look at where we’ve come from and where we’re about to go when it comes to the state of the ready-built 3D printer market.

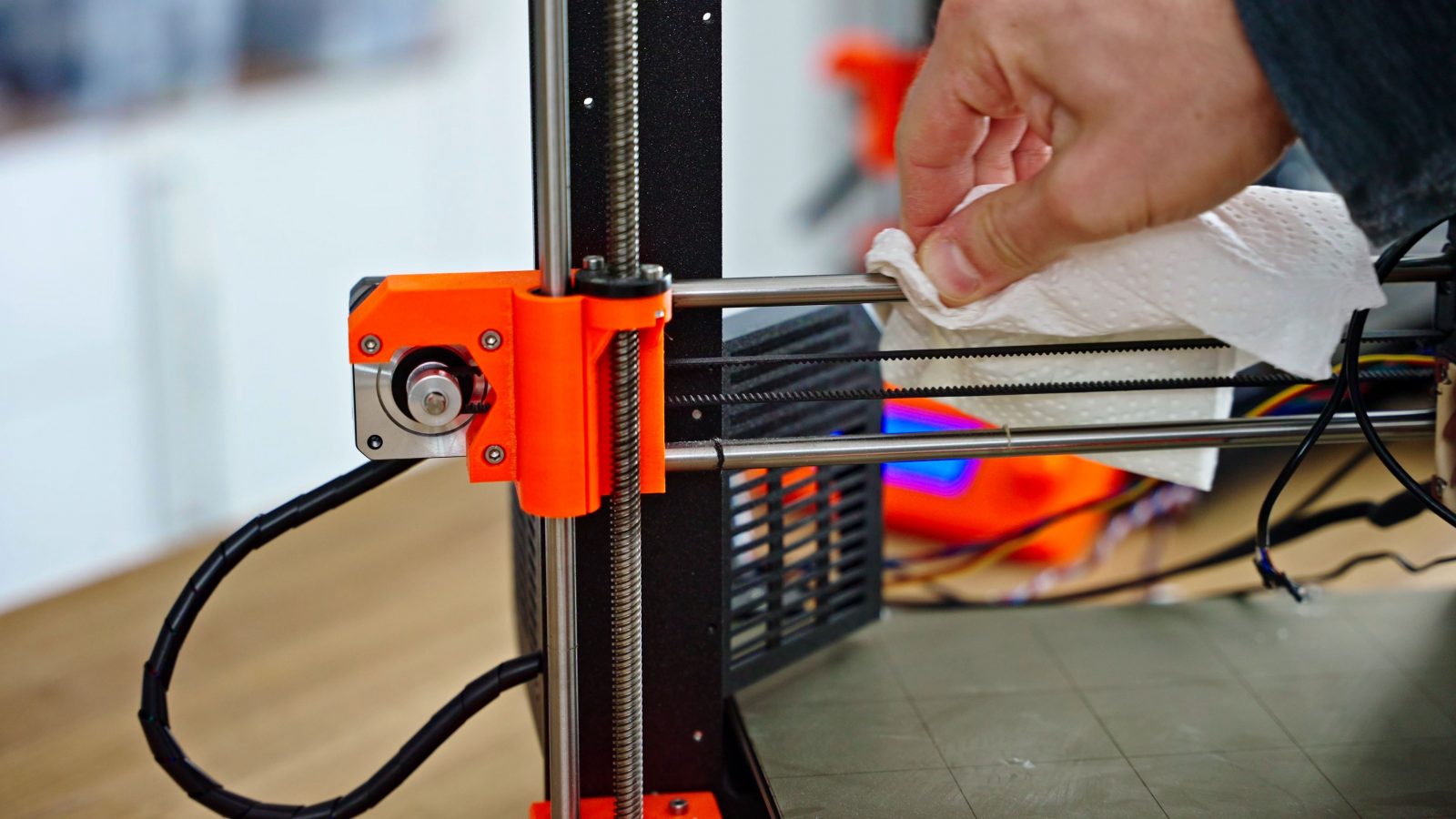

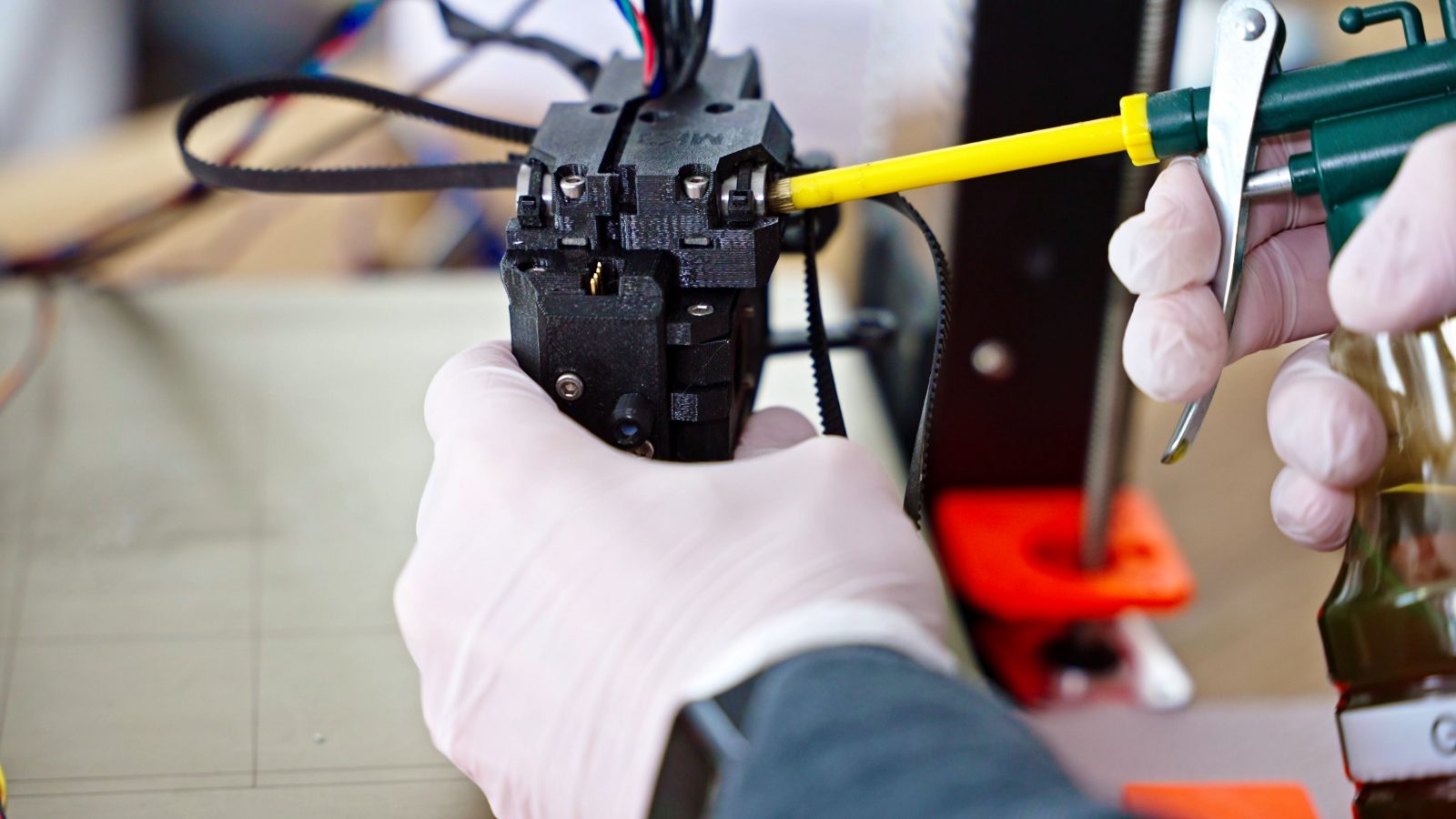

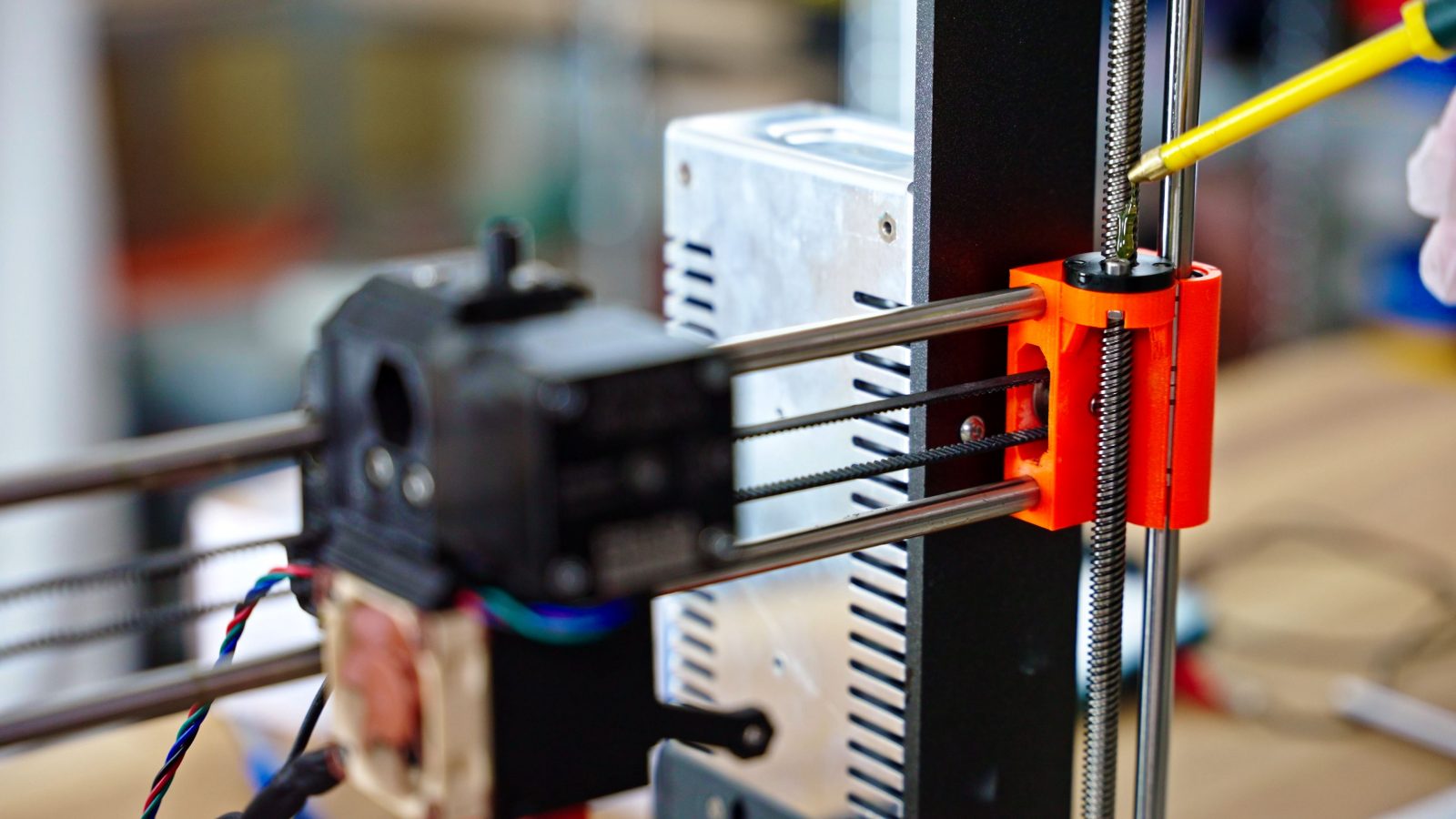

Okay, we’re back in business! We’ve now gotten rid of the Volcano hotend and the weird third-party heatbreak, it’s got a new PTFE tube, all the bearings are fully lubed up, I’ve got the angled part cooling fan mount on there, and a new SuperPINDA probe. And while I was at it, I also gave it a new 0.6mm steel nozzle and a proper textured PEI sheet. It prints beautifully! This printer has been properly mistreated and neglected – most of it not by me – and it’s now back in perfect working order. It’s now back in its stock configuration. “Ze Auto has been un-pimped”.

And arguably, for me at least, this is the best possible configuration of the Prusa MK3. No weirdness, nothing to worry about, just slice your files with the stock PrusaSlicer profiles, chuck the SD card into the printer, and reliably get parts out.

This really is the recipe that makes me use the MK3 more than any other machine that I have. Is it the best and most advanced printer? No. Is it the one I enjoy using the most? Yes.

And I think I need to point out an important detail here. I’m not saying that this is the best printer out there, or that it’s the best printer for every use case, or even that I’m recommending that *you* should get a Prusa over other choices. Though some people certainly make it sound like that’s what I do, but I don’t. If you want a machine to tinker with, get one of the many Ender-3 variants. They’re pretty solid printers and there’s a huge community when it comes to mods and upgrades. Sure, all the doors are open for that on the Prusas as well, but I’m not sure if you’re actually going to be improving the printers or the overall experience by changing and modding things. Likewise, if you’re using 3D printers commercially and need more than what this guy can offer, certainly, get something better suited to those needs.

What I think needs some acknowledgment, too, is how long Prusa has been around and how much their contributions have added up in the 3D printing space.

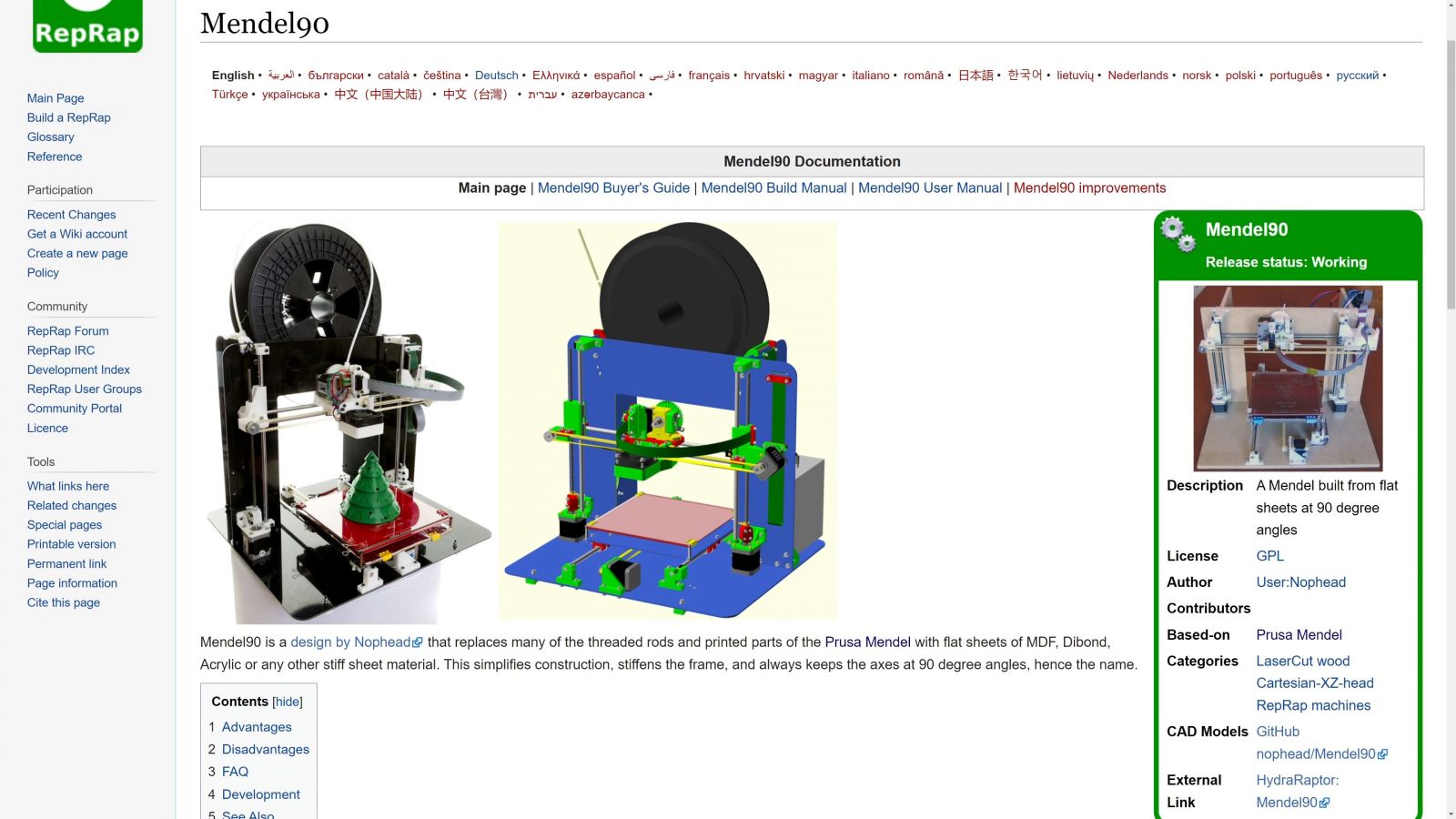

Arguably, without the first Prusa Mendel – which, back in the day, was a version of the Sells Mendel that people could actually reasonably build – without that printer, who knows if 3D printing would even have taken off like it did? And if you take a closer look, the design of 99% of the printers out there is based on the Prusa i3 design, or the Mendel90 one, which likewise is also based on Prusa’s designs.

Many of the improvements that are starting to become mainstream now like coated PEI sheets, auto-leveling, filament runout sensors, silent Trinamic drivers, power loss detection, etc, were made popular in the first place – you guessed it – by the more recent commercial Prusa machines. How much you want to value that historical aspect of it is up to you.

But what’s definitely more tangible is how much effort they’re putting into the machines, even once they’ve already made the sale. These MK3s are now quite different printers than when I first got them. They’ve seen countless firmware updates that improved reliability, added features, or simply made for a better user experience. The same for the slicer, there is just one single version of PrusaSlicer that supports everything back to the old MK2, and even on that machine, you still get all the improvements that each update brings along.

Now, I get that those are all things that are quite hard for a brand-new manufacturer to match – I mean, they can’t possibly have a track record of still supporting printers half a decade old or having already set trends that shaped the 3D printing industry for the better. Promises are easily made and, but time has shown, they’re even easier to break, so when someone new comes along and makes bold claims, I naturally get suspicious.

It’s great to finally see something new, like the Bambu Labs or Anker machines in a sea of practically identical Ender-3 clones. But with great promises also come great expectations, and at the very least, I expect the user experience and ease of use of what is supposed to be the new gold standard to be on par with what I’m used to from these old boys. So far, on the printers that I’ve used, I think it’s still unmatched, but I’m very excited for the day that someone manages to one-up the game.

Thanks for watching, keep on making, and I’ll see you all in the next one.

Relevant products: The MK3 (of course)

💙 Enjoying the videos? Support my work on Patreon!

Product links are affiliate links – I may earn a commission on qualifying purchases (at no extra cost to you)

Check out my second channel “More Layers” on YouTube for livestreams