E3D’s Revo and ObXidian Nozzles

E3D’s Hermes, or now Hemera, introduced a new, compact heatbreak mount. A couple of years later, the reason for that became clear: There’s a whole new ecosystem of hotends, extruders, and integrated nozzlebreaks that all revolve around this new form factor that makes nozzle swaps faster and printing more reliable.

E3D was calling it Revo. But… there was a small problem. Only E3D are allowed to make nozzles for it, and the only nozzles they were making were plain brass. Which meant you could only print with filaments that were non-abrasive.

But E3D knew about this, and they promised they would make a nozzle to end all nozzles. They called it… the ObXidian.

It’s just that that was really it. There were promises of it being available “soon” for almost a year, then when it was finally scheduled to be unveiled, that release got canceled on short notice, which was frustrating for me, I had an ObXidian, and I wanted to have a video on it available at launch and had spent a bunch of time on it, but when the launch got canceled, I had to shuffle and find a different topic I could produce a video on in just a couple of days to stick with my two-week release schedule, and when the ObXidian was then finally actually released, E3D gave a generous three business day notice to please have your content ready on launch. Well, I don’t typically keep videos around just waiting to be released, so what you’re watching now obviously isn’t the launch video I was hoping to make, and since I assume just how well the ObXidian prints is now already well covered by everyone else, I’m going to do something that nobody else is doing: I’m going to attempt to destroy it. For science. And hopefully, it will put up a bit more of a fight than this powderized brass nozzle.

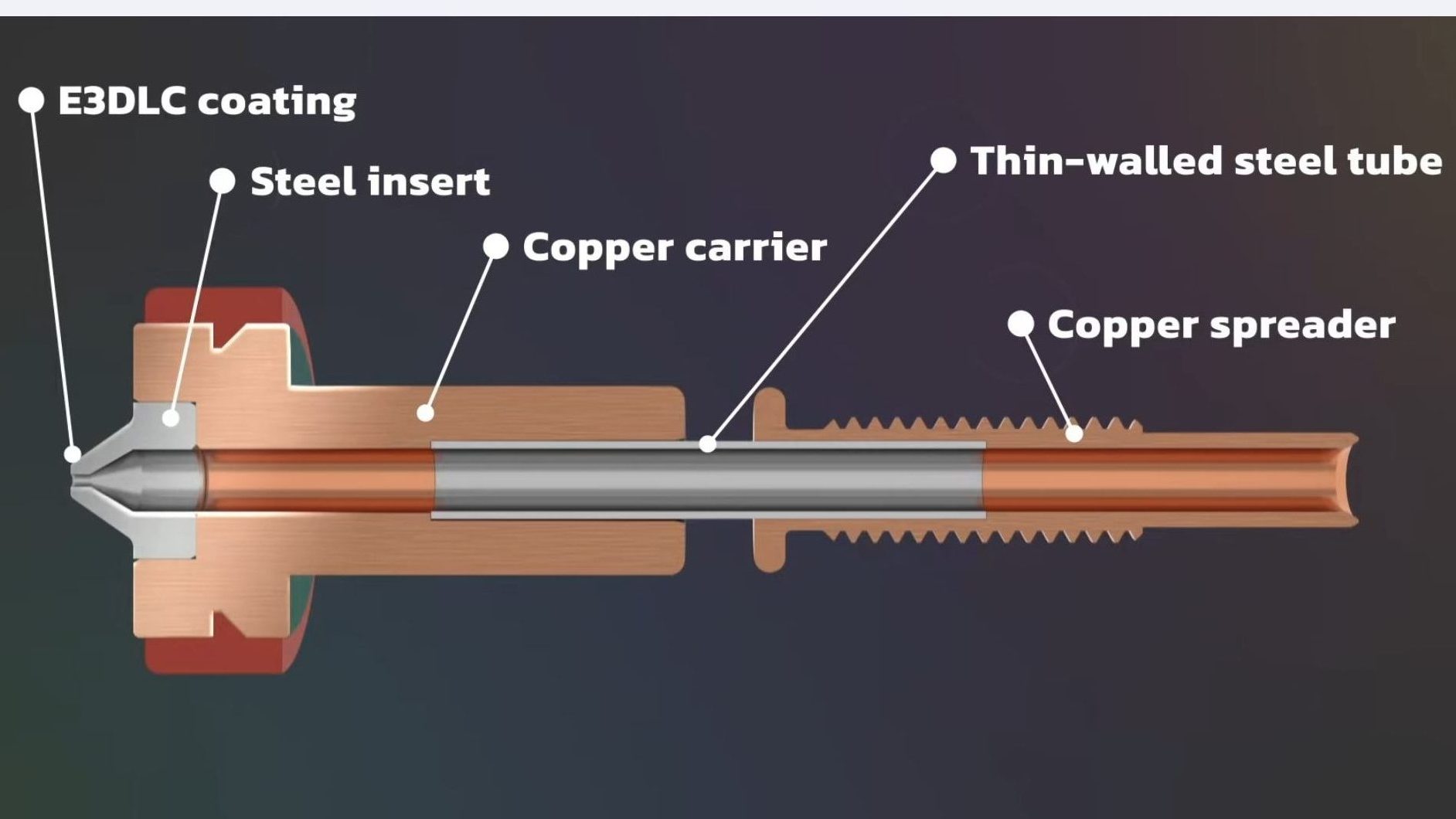

So… the ObXidian. First of all, this thing has nothing to do with actual obsidian, other than, it’s black, it’s shimmery, and it looks cool. There are nozzles out there like the Ruby nozzle that actually use an inserted gemstone, the ObXidian also has a hard insert, but real obsidian would be a pretty poor choice for that, it would be a cool novelty, but obsidian, being a volcanic glass, is rather soft, brittle, and not very wear resistant. Instead, the ObXidian uses a hardened tool steel insert, pressed into a copper body, and then all of that is coated with what they call E3DLC.

Their materials seem to be a bit reluctant in actually explicitly saying that “E3DLC” is an actual diamond-like-carbon coating, as the name implies, so I asked them, and they confirmed that it’s mostly a diamond-like carbon coating, but the design goals for their version of a DLC seem to be a bit different from what you would typically tune the coating process for, usually you’d want a very thin and hard layer. Instead, one of the main things E3D tuned for was keeping plastic from sticking to it, you know, those black boogers that you sometimes find on your parts, those should be mostly eliminated, and also, I guess the nozzle would not drag on freshly extruded material as much, which might slightly improve things like overhang printing performance?

I have not printed with this, like I said, I think that’s already well covered. I tested the Revo hotend when it first came out, using the original brass nozzles, and that’s a good hotend. It prints well, and it has better throughput than v6, of course, it’s all proprietary, but honestly, when E3D make a new product, I kinda trust that it’s not going to be a total dud. Sure, there might sometimes be some issues that only pop up at volume, and that really only is relevant when you have a high expectation of quality to start with, and those are things like the bearings in some of the Titan extruders failing too quickly, or the gears in some of the Hemera extruders cracking. Those cases are rare, and I think they’ve been handled well by E3D in the past. What I’m saying is that E3D will have tested the performance of their products, especially ObXidian, their flagship product, to their best ability, before they put them onto the market. I’d rather have a product that is late, but well executed, instead of one that was rushed and is on time, but just ends up being frustrating overall.

So what I can do is go past what E3D could have tested and see just where the limits are. And in this case, that means testing wear until something gives.

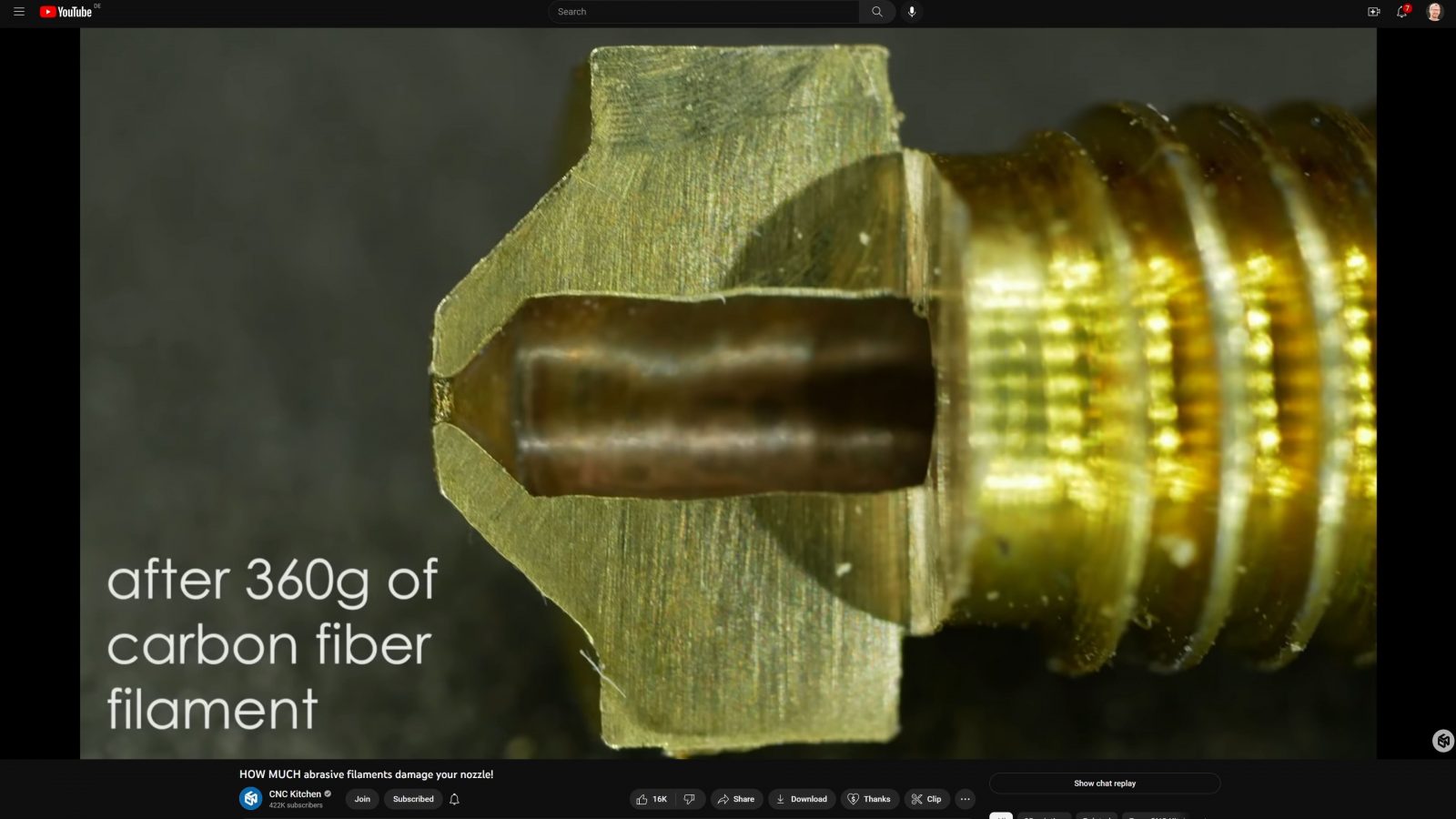

Stefan on CNC Kitchen has concluded in the past that the majority of a nozzle’s wear, when printing abrasive filaments like glow-in-the-dark or carbon composites, that wear is happening at the very tip of the nozzle, and not as much in the bore itself. That’s what I’m going to try and replicate.

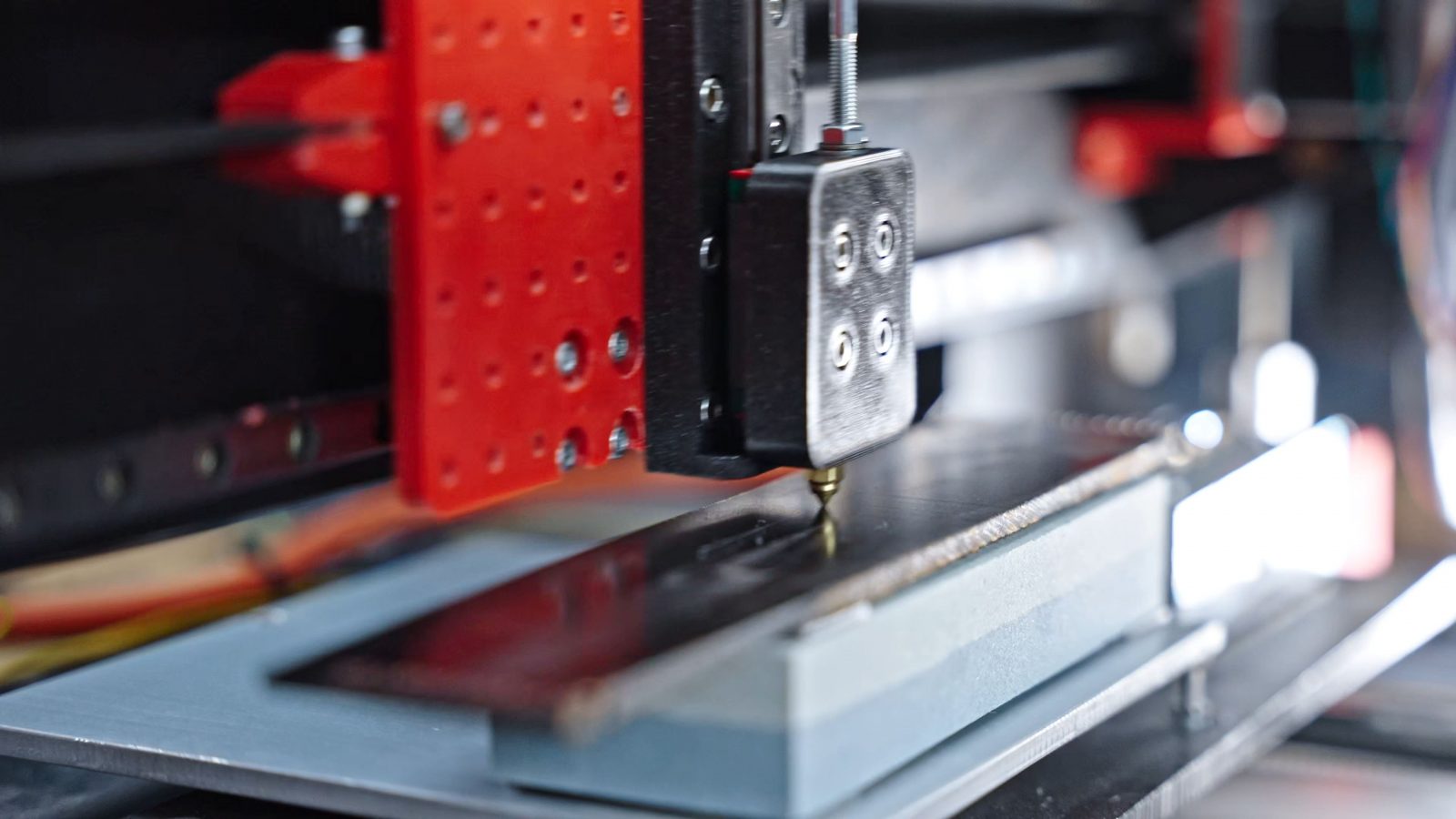

Time to build a nozzle destroyer!

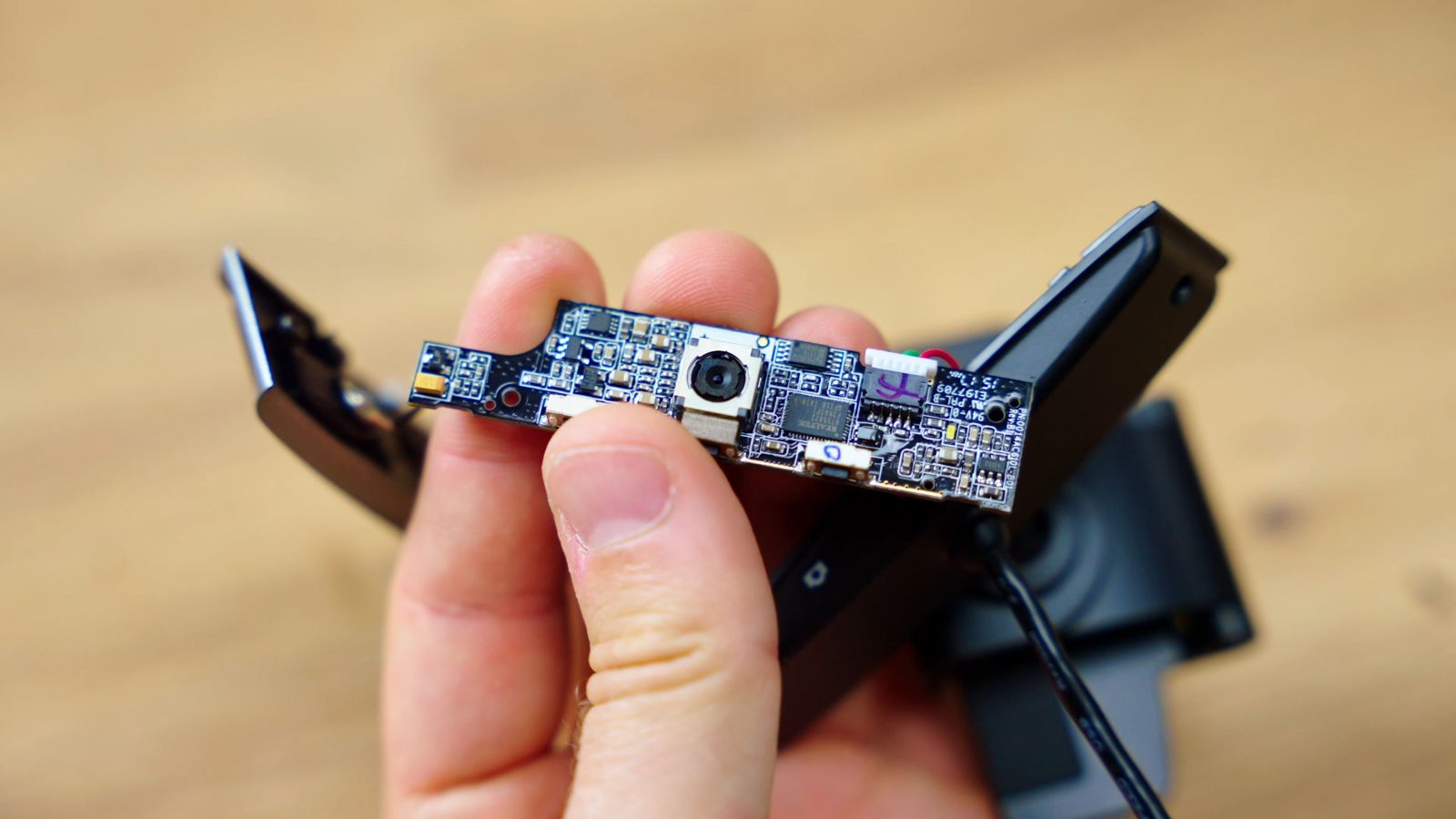

My Nozzle Destroyer Setup

So this is it. We’ve got the nozzle in a little slide, free to move up and down, we’ve got our test medium at the bottom here, and gravity is pushing the nozzle into our medium. In this case, a sheet of carbon fiber. As the nozzle rubs across that, that should somewhat simulate it rubbing across a carbon-filled print. Now, the kicker is this guy over here. This is a webcam! Full 1080p, though the image doesn’t quite look like 1080p, but I’ve tweaked the focus so that we get a nice close-up macro shot of the nozzle. Now, originally, I wanted to use Octolapse to create a timelapse for me, but since my torture gcode doesn’t really have any layers and I couldn’t get the manual gcode trigger to work, I ended up just writing a quick python script that remote-controls OctoPrint and grabs images off of the webcam feed remotely using OpenCV. Because why not. OctoPrint has a fantastic API that just made this super easy.

So the way I’ve set up the nozzle destroyer is that it will start over the camera, that’s the home position, then it moves over to the starting point, drops the Z-axis, which gets the nozzle riding on our grind medium, and then moves back and forth 20 times, picks the nozzle back up, or at least what’s left of it, moves it over the camera, takes a snap, and over the next 8 hours, it repeats all that 1000 times for a total of 4000m of dragging the nozzle over our abrasive material. That’s a pretty brutal test.

So in the end, each frame in the nozzlecam’s timelapse is 4m of grinding apart.

Grinding over Carbon Fiber

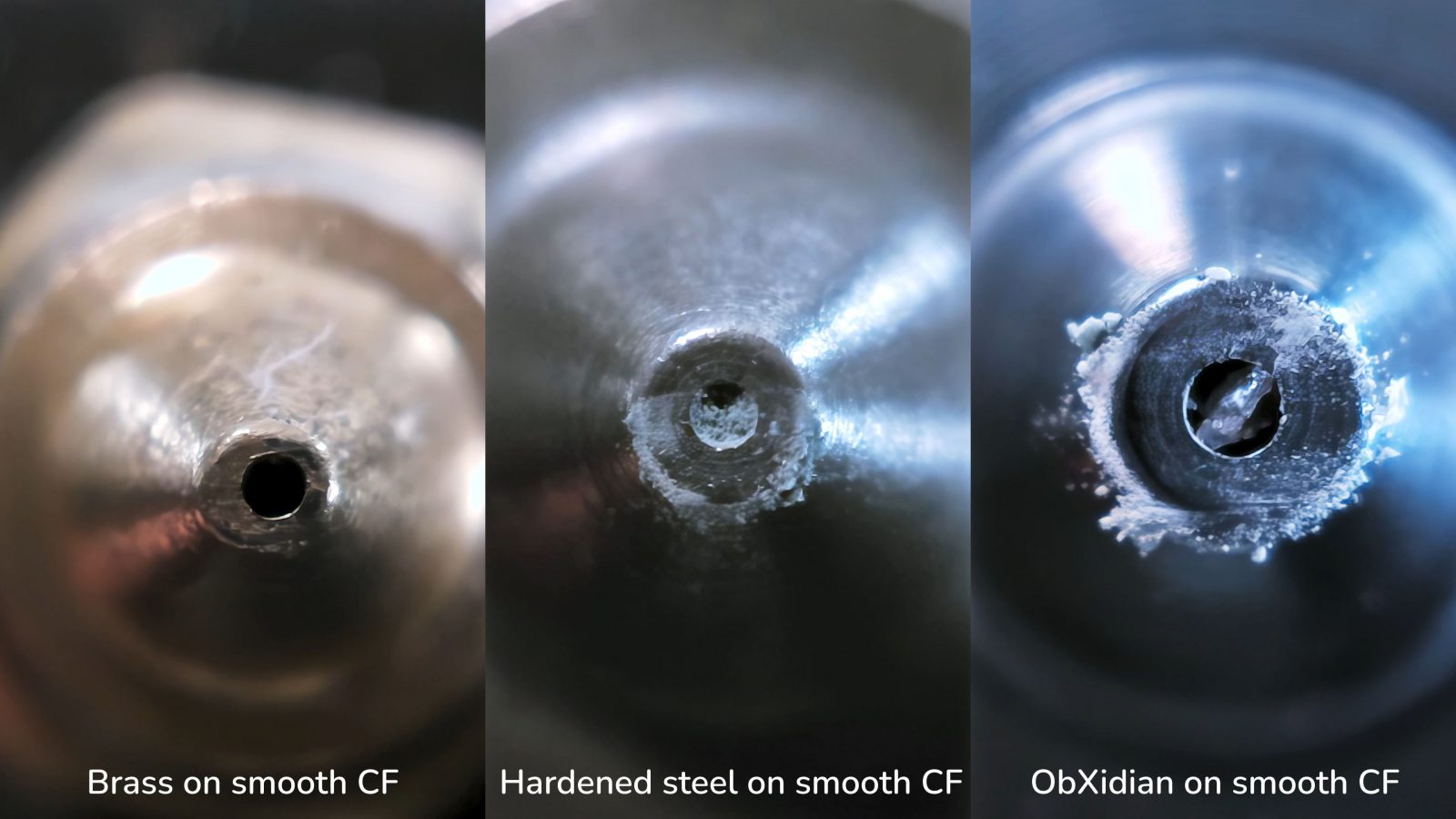

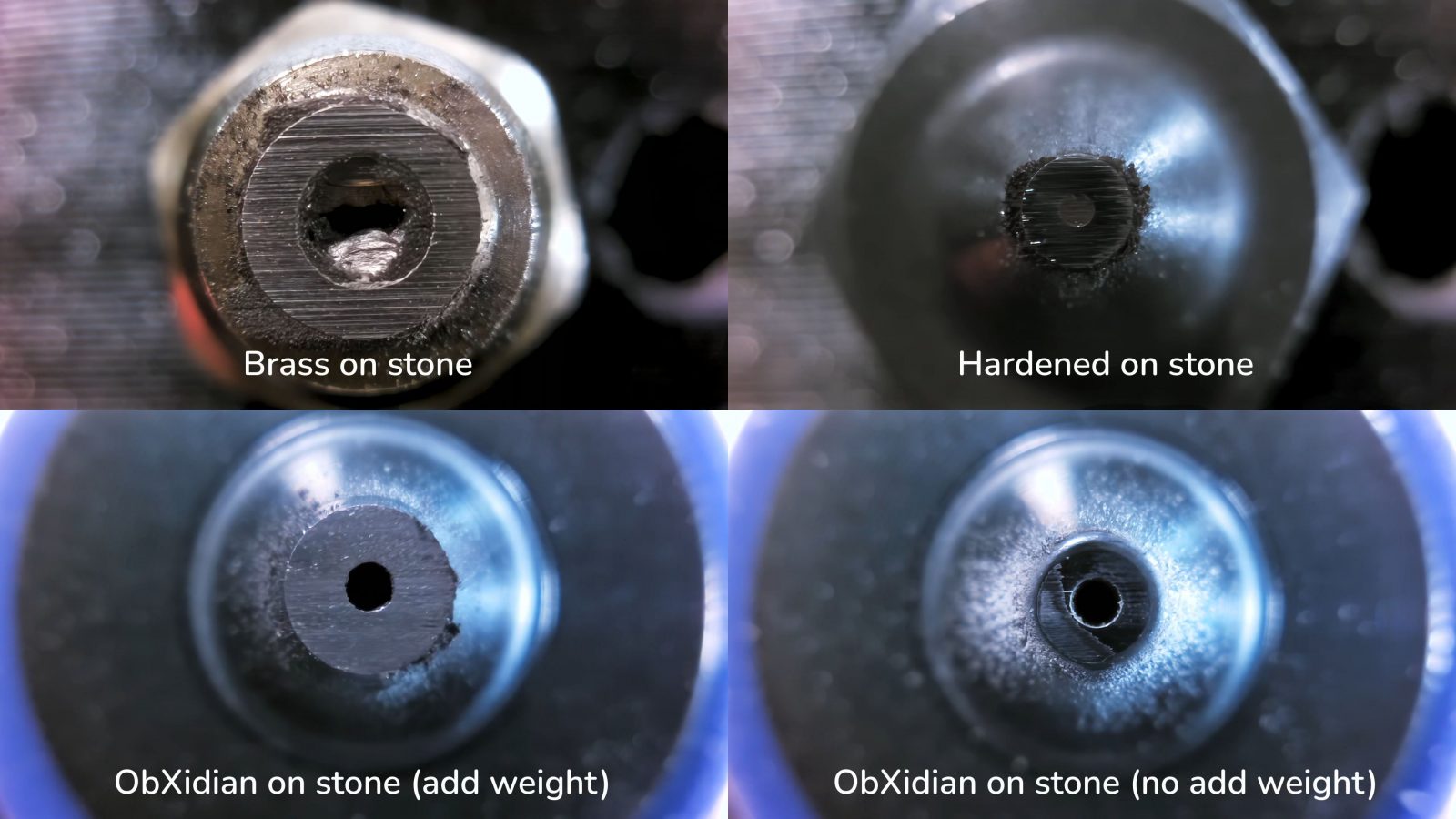

And what you’re seeing now is the very first one I did! It’s a cheap brass nozzle getting dragged over a plain carbon fiber sheet. This thing. Now an E3D hardened steel one. Uh, ok, there’s something happening, finally the ObXidian, and it’s not much different. Most of all, none of the nozzles were affected by this at all, noticeably.

A couple of notes here. First of all, these are all different nozzles. The brass one has a super pointy geometry, so the approximately 40g of force from gravity creates a bit more pressure than the less pointy hardened steel one and on the ObXidian, that same force gets distributed to an even larger area because E3D only sent me 0.6mm ones. The box said 0.4, so I thought I had comparable nozzle sizes, but I don’t, so I’m trying to make up for the roughly doubled area of the 0.6mm tip by roughly doubling the force pressing down on it. That turned out to be only a mildly smart idea. But we’ll get to that later.

For now, it doesn’t look like this carbon fiber sheet made any sort of an impact on the brass, hardened or ObXidian nozzles, even though carbon fiber is supposed to be one of the more abrasive materials these nozzles – typically – touch.

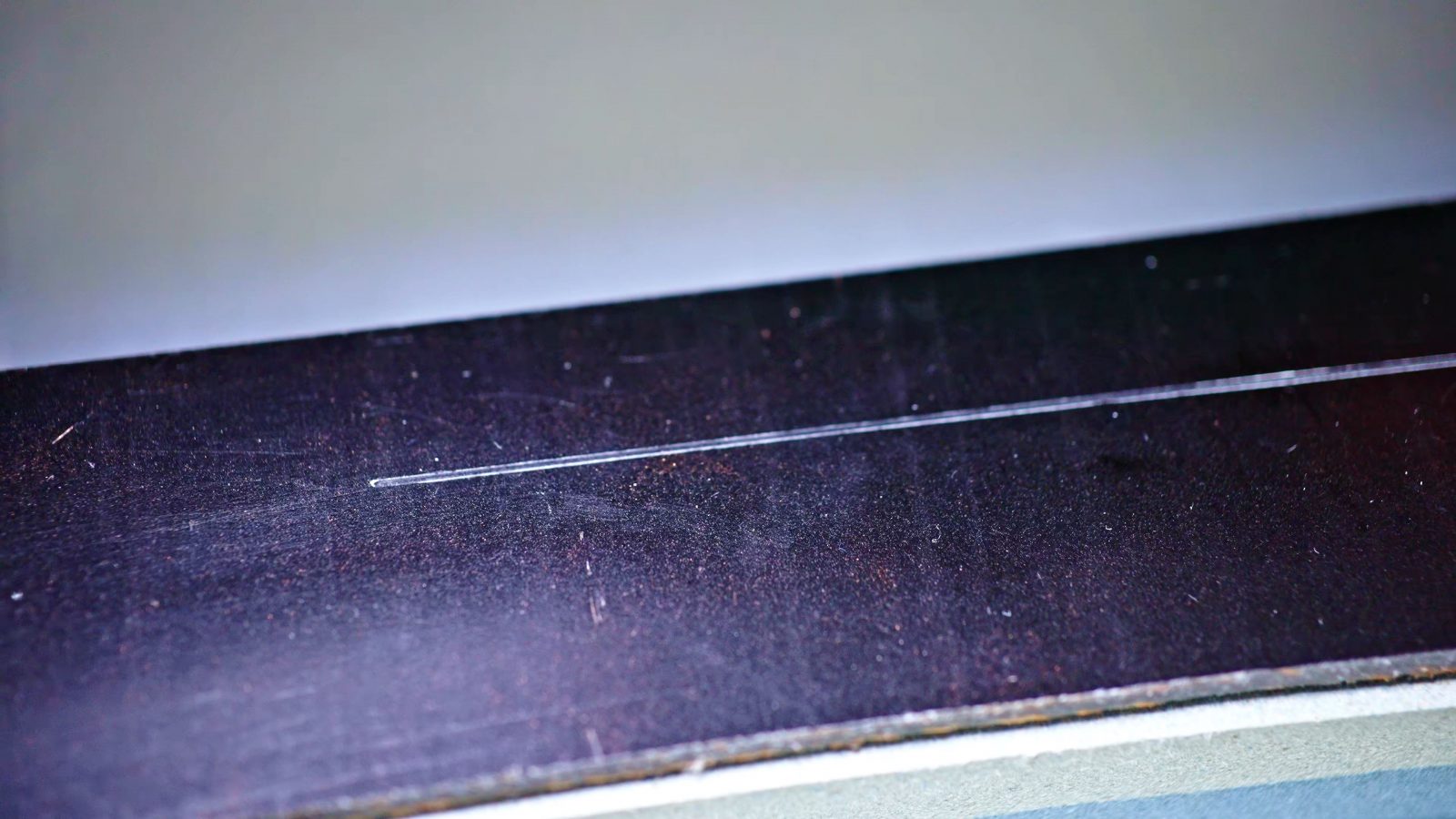

And I think that’s because the nozzles aren’t actually making contact with the fibers themselves, they’re just making contact with the resin impregnation in the carbon fiber composite sheet. You can see the shavings and the flakes are white or clear, and not black like the carbon fibers themselves. I could let these tests run until one of the nozzles finally breaks through the resin layer, or I could slightly help it along. Of course, that’s what I did.

Sidenote, carbon fiber dust is extremely nasty, always wear a mask when cutting or grinding it and have some good dust extraction. But this is now properly roughed up, and we definitely have the bare fibers exposed. Let’s go again!

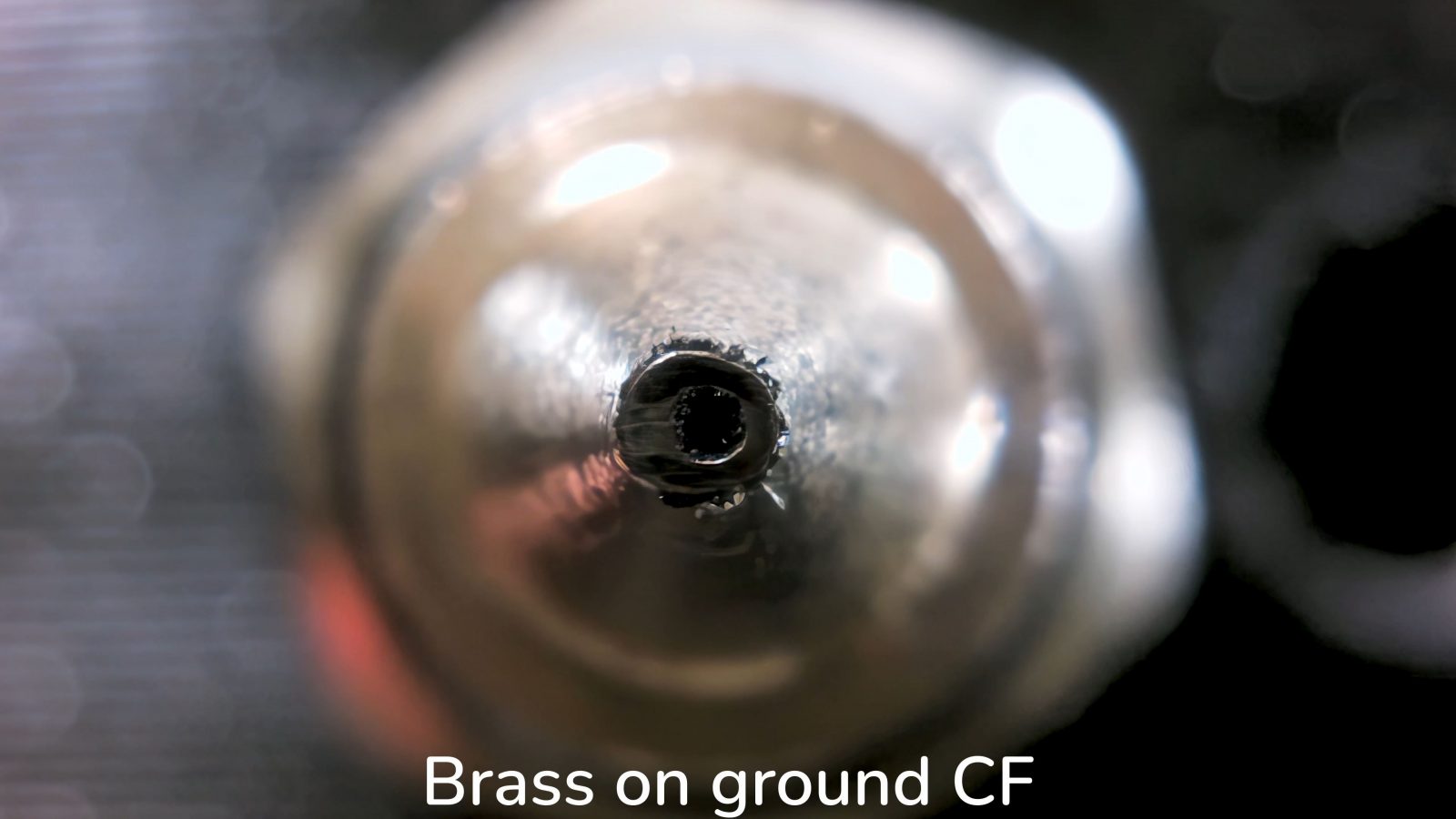

The ObXidian and the hardened nozzle again don’t seem to be affected by the grinding much, if anything they look like they actually just got polished or wiped clean by the fibers, I was able to measure a marginal reduction in length on the hardened nozzle, it went down 5 thousands of a millimeter, but that could easily be, I don’t know, thermal expansion or something. I did measure something, but I’m not sure that it’s actually wearing.

The brass nozzle, however, did definitely see some wear this time. You can see it getting polished away essentially and ended up losing almost 1/10 of a millimeter in length. Now, this is significant. It would definitely mess up your nozzle height offset, but assuming that actually printing carbon fiber would wear away the nozzle in a way that also smoothes over the edges, this nozzle would be way past usable at this point. Honestly, I didn’t think carbon fiber would eat into brass this quickly.

But here I was struggling. We saw that brass wears more easily, but we already knew this. So how do I figure out if the E3DLC coating on the ObXidian improves wear over a plain hardened nozzle? I really couldn’t think of a surface that was a little more abrasive than carbon fiber and would last through an 8-hour test. That kicked out polishing compounds, those would need to be reapplied constantly, and everything else just seemed way too aggressive to actually test with. But I needed something that would at least eat into the hardened steel. And the only things that do that are grinding materials. So I went straight to the sharpening stone.

Grinding on Sharpening Stone

Obviously, you’ve already seen it on the machine, that was the plan, or at least the backup plan all along, you’ve seen the thumbnail, so here we are. This is a cheap aluminum oxide stone, it doesn’t say which grit it is, but I’d guess 800 or so on the “fine” side, so it is pretty coarse and aggressive, just as a disclaimer to start with.

And when it comes to just how aggressive this is, here’s what it did to the brass nozzle. It’s gone. I even had to stop the test halfway through and readjust the zero position because the nozzle was now so much shorter that it was completely out of the camera’s focal plane. I mean, I could measure how much length we lost, but I honestly don’t quite see the point in that. There’s just not much left.

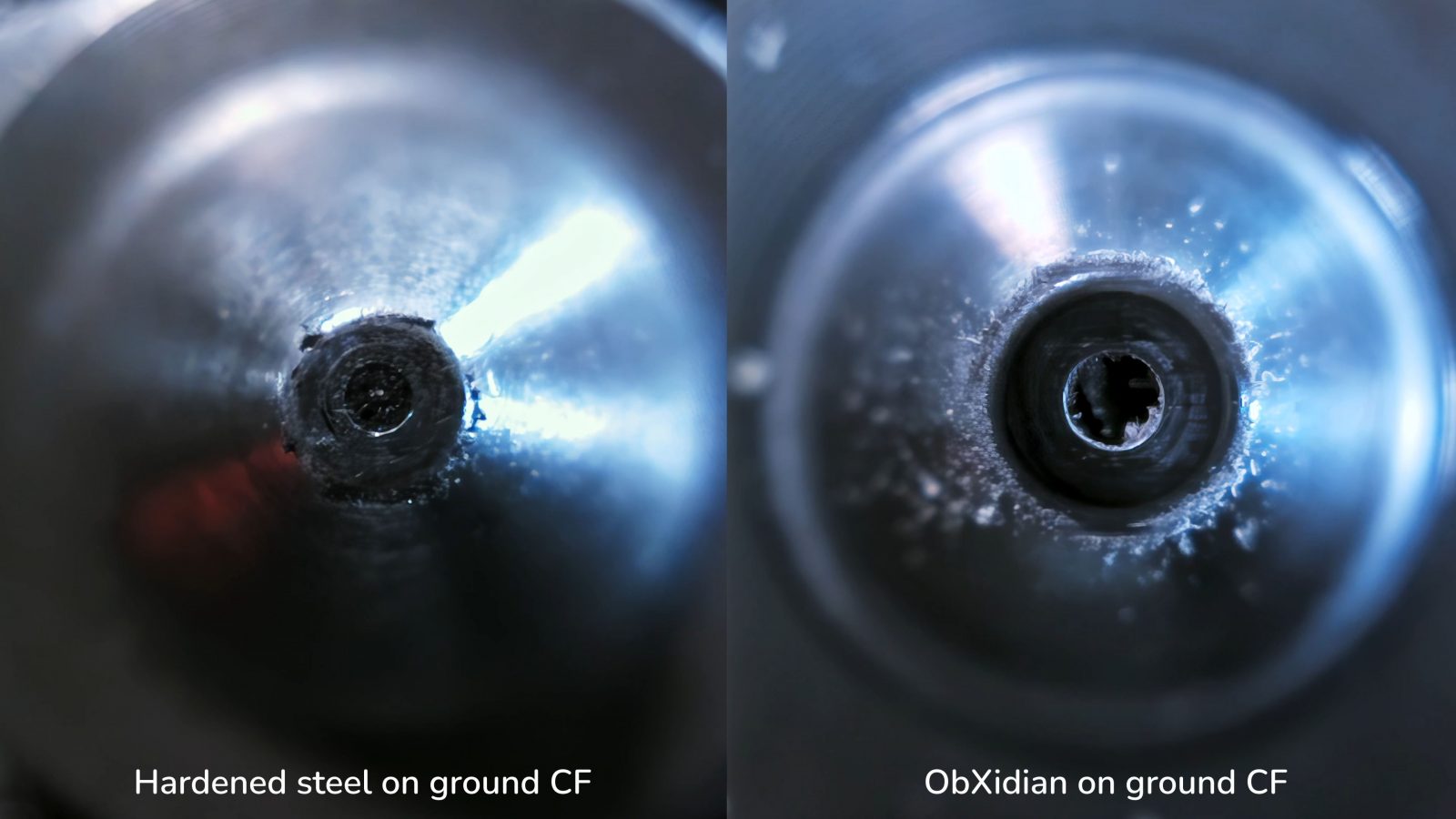

The hardened steel nozzle fared much better, but it still lost quite a bit of material. I don’t think I’d still want to print with this one, either. Now, something interesting is happening with this one, and it’s that the grinding progress seems to slow down the more the nozzle is already ground away.

This could be either the grindstone having worn away and now being “dull” essentially. Or, what I think is also very plausible, is because the contact area of the nozzle gets larger as it wears away, but the downforce stays the same, the actual pressure pushing the steel into the grinding medium reduces to a point where the grit isn’t digging into the steel anymore, but rather you get sort of a skating action where the nozzle mostly skips over the grit.

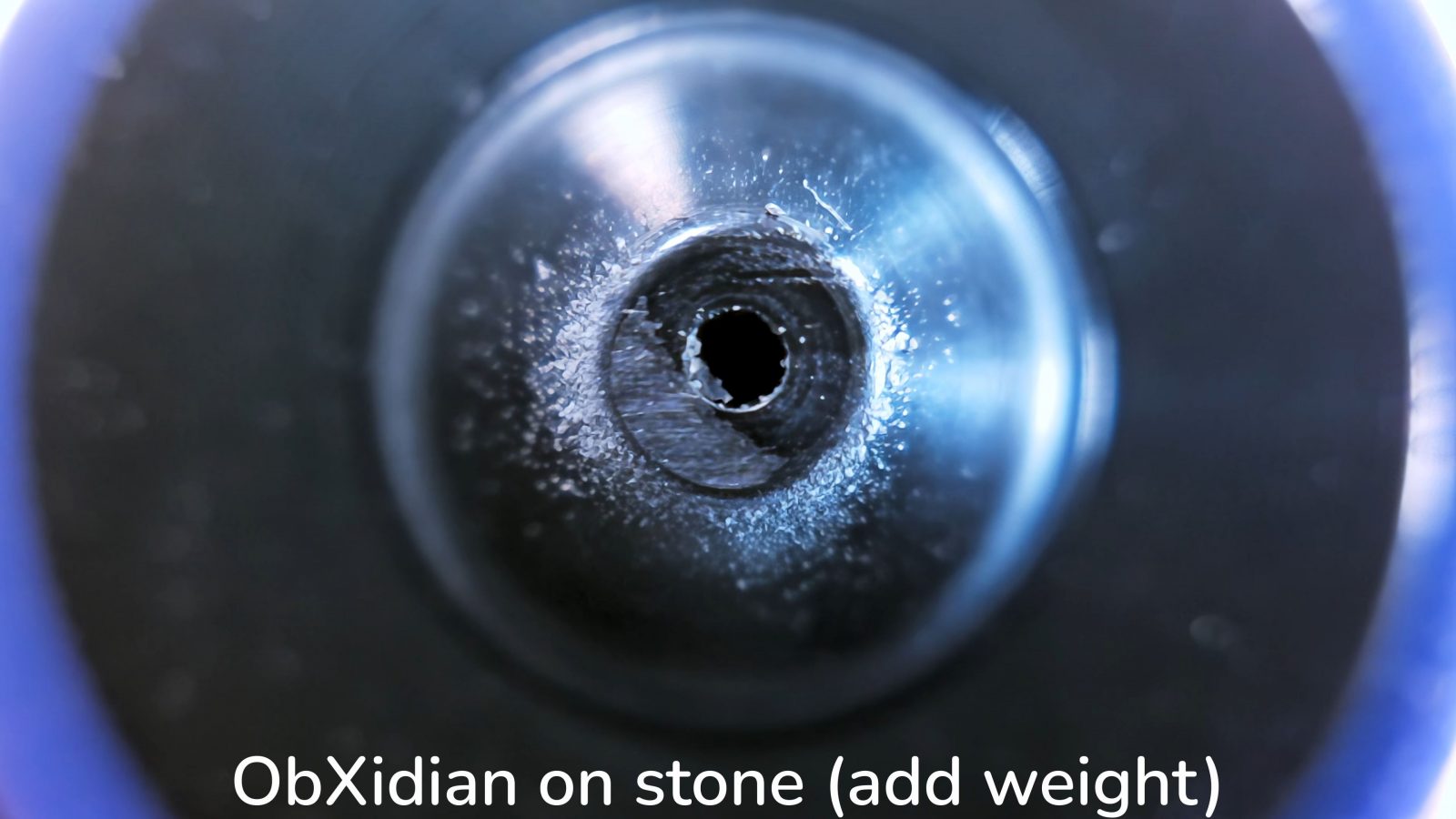

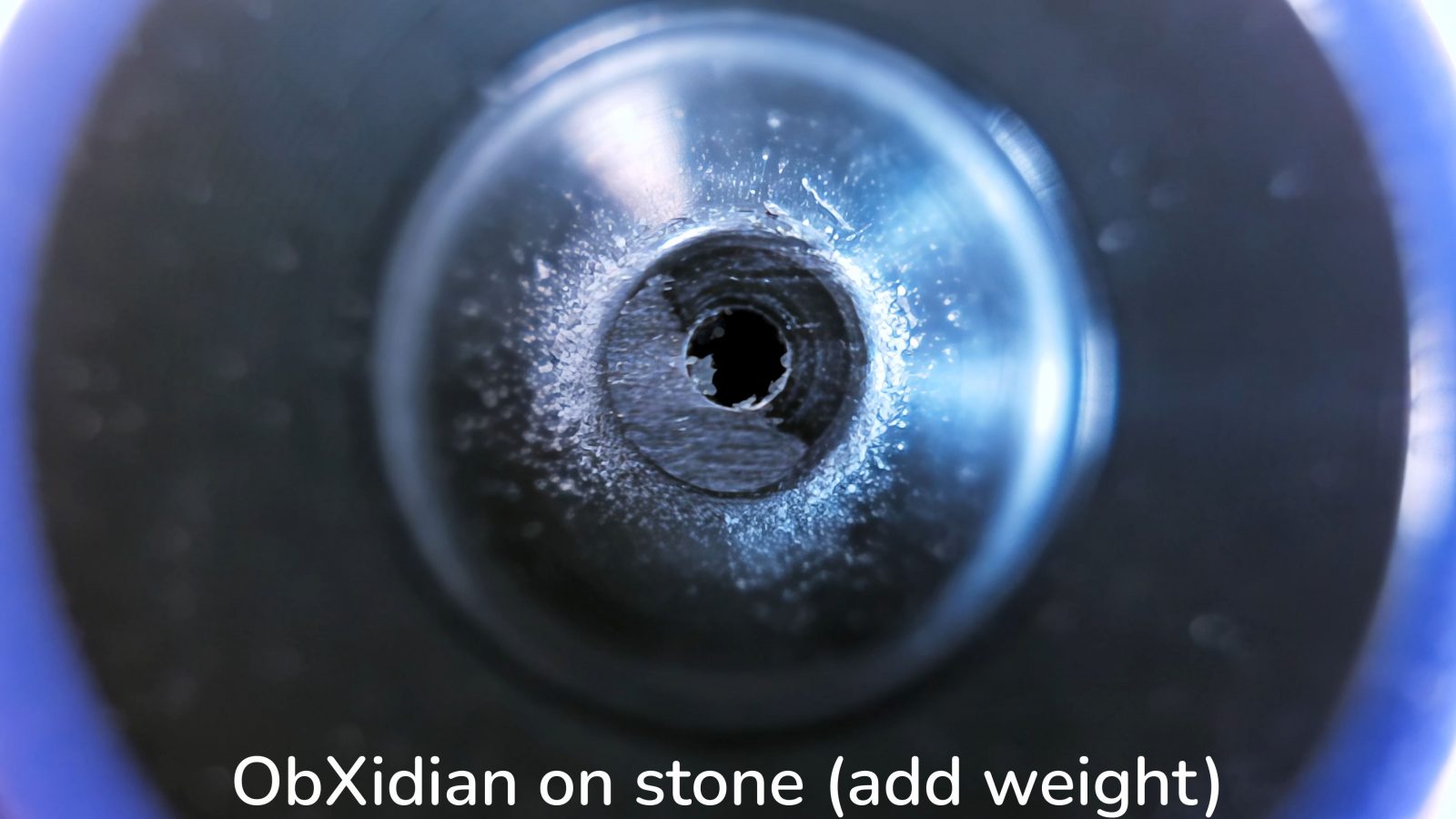

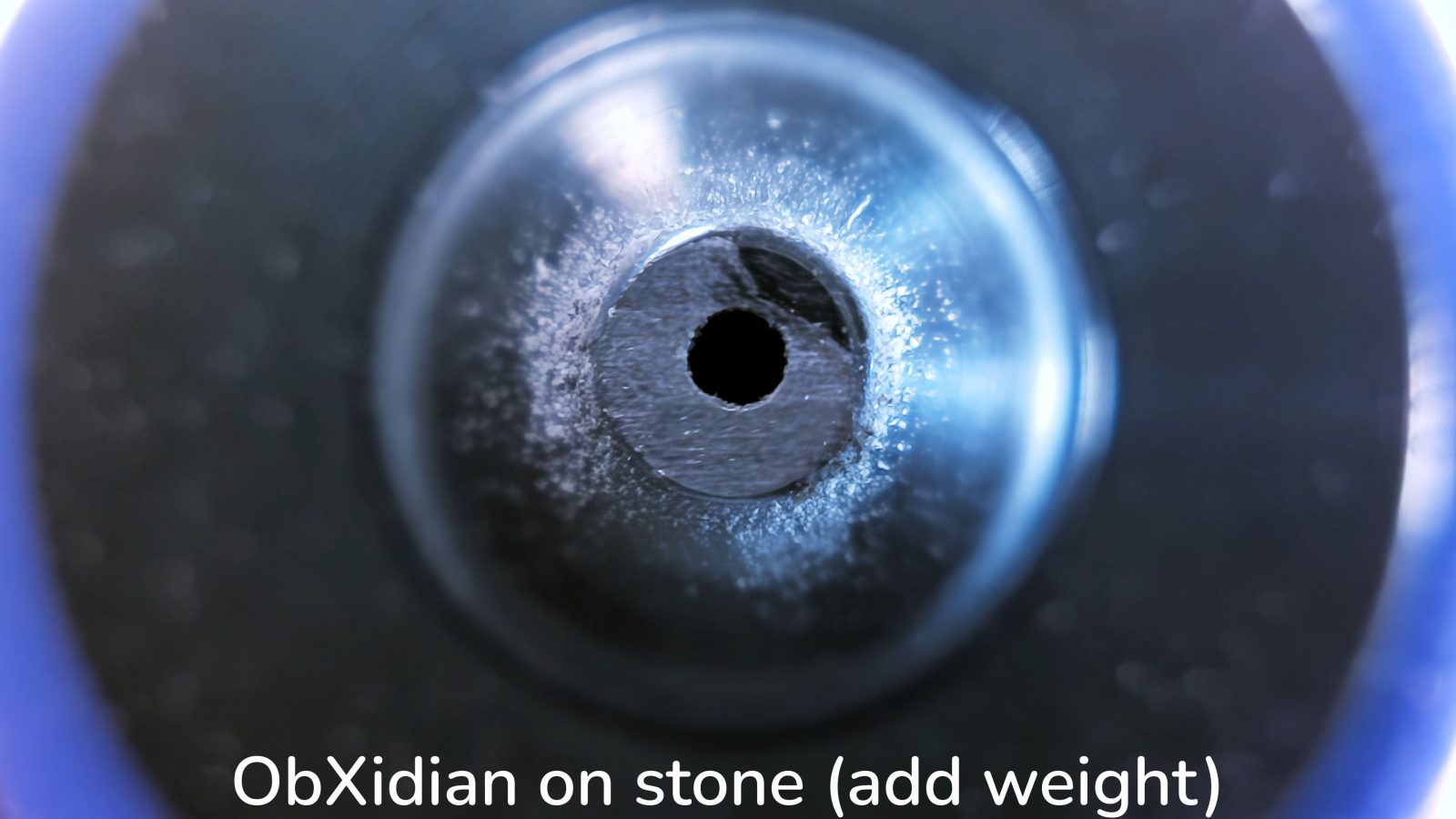

So, the ObXidian. Well, this one got obliterated, too. Much more so than the hardened one, actually. Now, I spent a couple of days thinking about how that happened. In theory, it all worked out. I had twice the surface area at the tip because this is a .6 and the others were a .4, so with double the force on it, it should be comparable. But, as always, things aren’t quite as perfect in practice.

Because what you can clearly see is that we didn’t actually get the entire tip to make contact, it was just one corner at the start taking the entire force, where we immediately ate through the coating and only then slowly started gaining contact area, but at that point, we’re mostly grinding at the hardened steel core and not at the coating anymore. And that’s making the ObXidian look worse than it is. In practice, the coating is all that’s going to matter for longevity, if you ever make it through that, the nozzle is past its useful life. Now, the first couple of grinding cycles tells us a lot about what’s actually going on:

Look at the hardened steel again, within a single cycle, we’ve ground it down enough to make full contact, and every subsequent cycle then evenly eats into the material more and more. But with ObXidian, it takes a good ten cycles to even grind it to the same size contact patch that the hardened steel one was at after it’s first one – and that is with twice the amount of force on the ObXidian driving it into the stone.

But this didn’t satisfy me yet. Having tested the ObXidian with essentially too much weight meant that the results wouldn’t be representative, even though there is a clear difference visible. So I did what had to be done – and I sacrificed the second ObXidian E3D had sent me. This time, with the same amount of weight on it as the hardened one – well, maybe in total a couple of grams more because the Revo nozzles themselves are a little heavier than standard v6 types.

And this time, wow, did the ObXidian last long. It still wasn’t chucked up perfectly perpendicular, but it took basically the entirety of the 1000 grind cycles to get to the same size of contact patch as a hardened nozzle reaches in just a single cycle.

There is barely any dust visible on the grindstone, and the dust we see on the nozzlecam is white, which has me thinking that we actually ground away more of the stone than of the nozzle itself. That is really impressive. So with these results, what I would conclude is that the ObXidian is at least 1000x more abrasion resistant than a hardened nozzle, at least in this setup. E3D, feel free to use that as a testimonial.

There is a whole lot more to this, though. E3D only rate the ObXidian up to 300°C. Is that because the hardened steel core slowly loses its hardness at those temperatures or is it because the carbon coating will diffuse into the steel at those temperatures?

Does the coating itself change properties as it gets hot? I would assume that the coating would perform just as well at high temps, while a bare hardened steel nozzle would abrade even faster.

My Conclusion on the ObXidian

And lastly, the most important question is, should you use an ObXidian? Well, from what I see, yes. They’re about twice as much as a regular Revo nozzle, so if you wear through just a single brass one, an ObXidian will already have paid for itself. Unless you abuse them as I did, or bend the heatbreak, the ObXidian should be the last nozzle you’ll ever need to buy. Which, honestly, is bad business for E3D, but it’s good for you if you have one. The affiliate link is in the description below.

Anyway, hope this wasn’t too long to watch. This was a lot of work and a lot of trying to make sense of the results, I hope you found it just as interesting as I did. You can support future experiments through Patreon or YouTube memberships, or just by sharing this video with your friends. Thanks for watching, keep on making, and I’ll see you in the next one.

Get the ObXidian at http://go.toms3d.org/obxidian

💙 Enjoying the videos? Support my work on Patreon!

Product links are affiliate links – I may earn a commission on qualifying purchases (at no extra cost to you)

Check out my second channel “More Layers” on YouTube for livestreams