On this channel, I talk a lot about 3D printers and 3D printing and making stuff that uses 3D printing, but chances are, you’re watching this and you DON´T have a 3D printer of your own. Well, should you get one? This video is the companion video to why you should NOT get one, so let’s get started on this one with 5 reasons why you should consider getting one. Reason number one, and this is obvious: A 3D printer is a tool, and an incredibly versatile one at it,Continue reading

Category: Tips and Tricks

Tips and Tricks for 3D Printing Beginners and Pros

Why you should NOT get a 3D printer

So you’re considering getting a 3D printer? Well, before I get you too excited with my other video about why you should get one, maybe first consider this video about why you should not get one. There are quite a few things that only become apparent once you’re in deep, and I’ve been in deep for the last decade. So here are five aspects to factor into your decision on whether you should get a 3D printer for yourself or even recommend getting one to a friend. Consideration number one:Continue reading

Free CAD

Are you tired as well, that seemingly the entire CAD landscape consists of extortionary licensing models that lure you into learning their tool for free and then slamming you with a massive subscription fee as soon as you’re hooked and start using it more? Or software that regularly removes features that you’ve grown to love? Well, worry no more, because there is an alternative, actually more than one, but for this video, I wanted to take another look at FreeCAD, a free and open-source, fully-featured CAD tool that is aContinue reading

Prusa Slicer 2.6

It’s a new year, it’s a new PrusaSlicer release. This one is 2.6, alpha 3 at this time at the time of me recording, and it brings with it some features that, each one on their own, are just, nice, but when you put them all together, it makes for an overall well-improved package. Of course, this isn’t just for Prusa machines, you can use PrusaSlicer with any 3D printer that speaks gcode, in fact, the 2.6 release now out-of-the-box has tuned profiles for the new Elegoo Neptune series, CrealityContinue reading

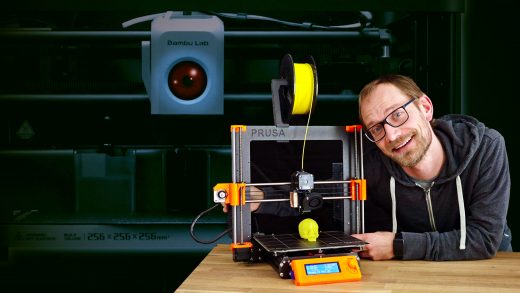

This printer is OLD. Why is it still my favorite?

This is my Prusa. There are many like it, but this one is mine. Actually, this one is exactly like all the other ones out there, except that I put an E3D Revo in it because I needed to review that hotend platform and it’s using a newer official model of the fan shroud because I melted off the one it came with at some point. But it’s still the printer I actually use whenever I just need to print stuff. This one, on the other hand, has seen someContinue reading

How to use a 3DBenchy

Hello from the new, old, old, new studio! I’m not quite fully set up in here yet, but it’s usable, and today we’ll be talking about Benchies! I don’t think I need to explain what this is – if you’re watching this video and you’ve got a 3D printer, you will most likely have already printed a 3DBenchy at some point. And I think that’s great! I’m going to argue that this is pretty much the ultimate calibration or benchmark print. I’ve never printed a calibration cube, well, maybe once,Continue reading

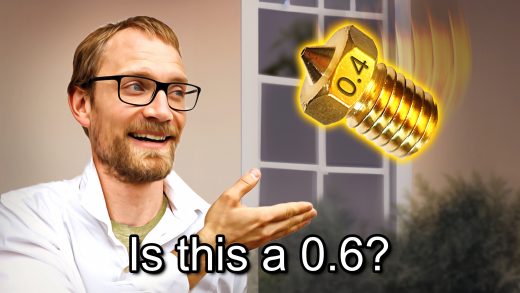

Get the benefits of a 0.6mm nozzle with a 0.4?

My “0.4mm nozzles are obsolete” video apparently left quite a few questions in need of answering, at least going by the comments on the video. So today, we’re going to look at whether you can maybe just stick with a 0.4mm nozzle and tell your slicer to pretend it’s a 0.6, how strength compares between nozzle sizes, and whether comparing 0.4 with an old slicer to 0.6 with a new one was even fair in the first place. I hope I didn’t hurt the nozzles’ feelings. So let’s start outContinue reading

Should you use a Reverse Bowden?

The job of a Bowden tube is to guide the filament from the extruder into the hotend so that the extruder can drive the filament over here, but the actual pushing force happens at the hotend. If this printer didn’t have one, the filament would get pushed just the same, but the driving force wouldn’t be able to push it into the hotend. Makes sense, right? But not every 3D printer is a Bowden system, in fact, this guy isn’t, but I’m going to argue it’s still going to profitContinue reading

Are you printing at the right temperature?

When you start a print, how do you decide what settings to use? Of course, parameters like the solid shell thickness or the infill percentage are something that needs to be decided on a print-by-print basis, but what I mean are the settings that, ideally you figure out once and then leave as a preset for future you. But what if those presets are wrong? What if you didn’t even tune those in yourself and use whatever the filament manufacturer suggests or stick with the presets that come with yourContinue reading