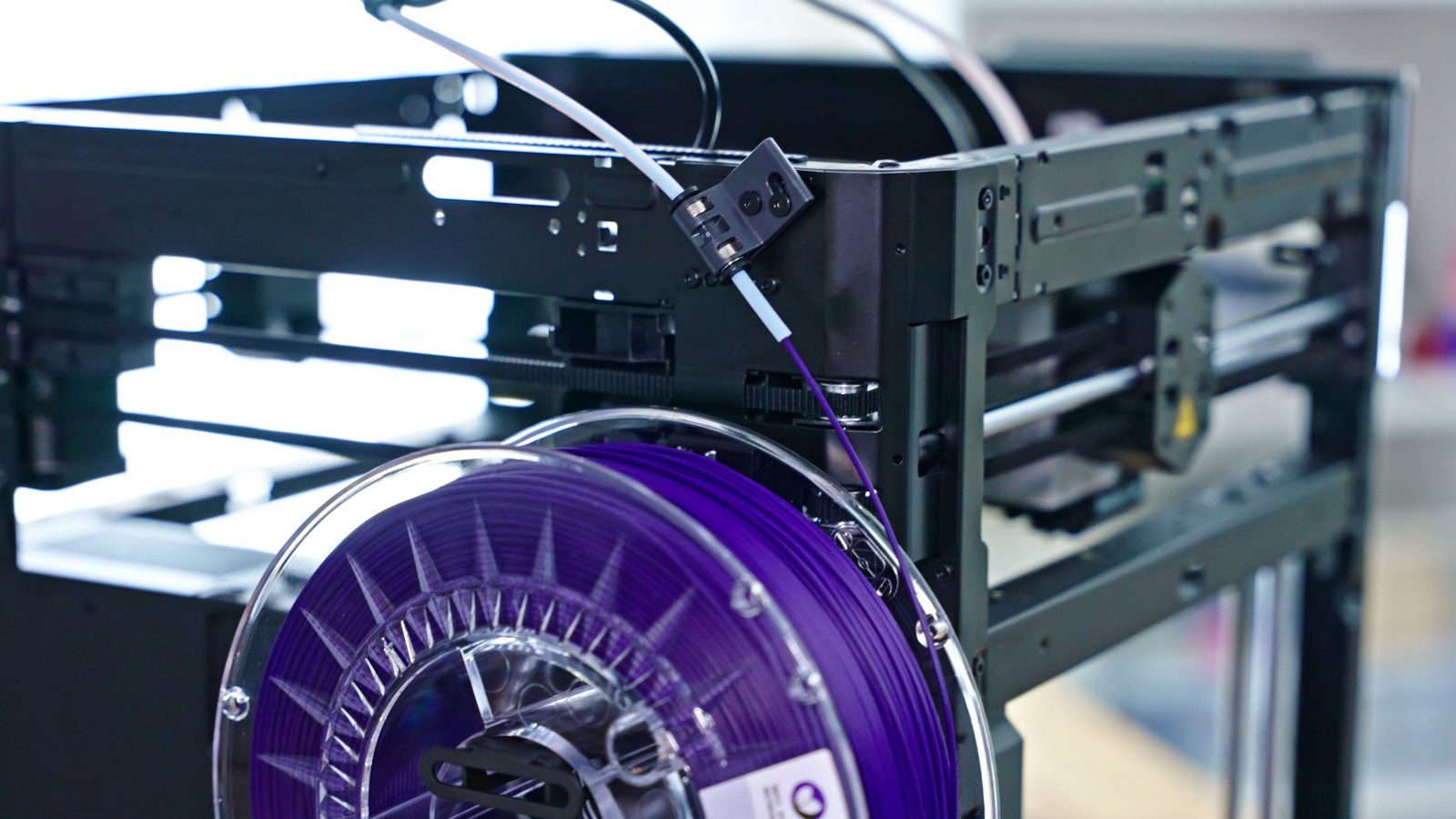

Yeah, it’s pretty fast! This is Bambu Lab’s P1P, and it’s basically one of their “prime” X1C printers with a lot of the parts just stripped away that you don’t really need for running the printer – and then some. This one clocks in at 784€ including tax, and while it is an incredibly impressive printer, especially at the price point, it’s sort of a weird mix of decisions between keeping high-end features from the X1C, stripping away others that honestly wouldn’t impact costs much, but then including some upgraded parts that not even the X1C comes with. With great hype come great expectations, so where exactly does the P1P fit in, and is it worth taking the risk on pre-ordering one?

So, first off, props to Bambu Lab for doing their homework, because their printers quite perfectly slot into a market segment that really needed filling. There are tons of machines at the low end around 200, 300 bucks. Then up to, like, 600 bucks, you can get the same cheap machines, but with some fancy addons or at larger sizes, but at their core, they are still that same super basic setup. Then, as you go up in price further, there’s a whole lot of nothing except for Prusas or Voron kits, until you get up into the 2,000 to 3,000 bucks range where you’ll start finding so-called “professional” machines that really market to a drastically different audience. Bambu Lab went for that that “premium consumer” market, where they’d only need to compete with the old MK3, or the purely DIY machines, but because they’re banking on moving a whole lot more volume than the much more expensive “professional” machines, they can cost-down some of the more advanced features and include them, too. And that really enables them to stand out – with the X1 series and now the P1P, the core is that they’re taking the print speed experience of a well-tuned Voron and they’re putting it into a machine you can just buy off the shelf and use at those same speeds with zero tuning or fiddling on your side.

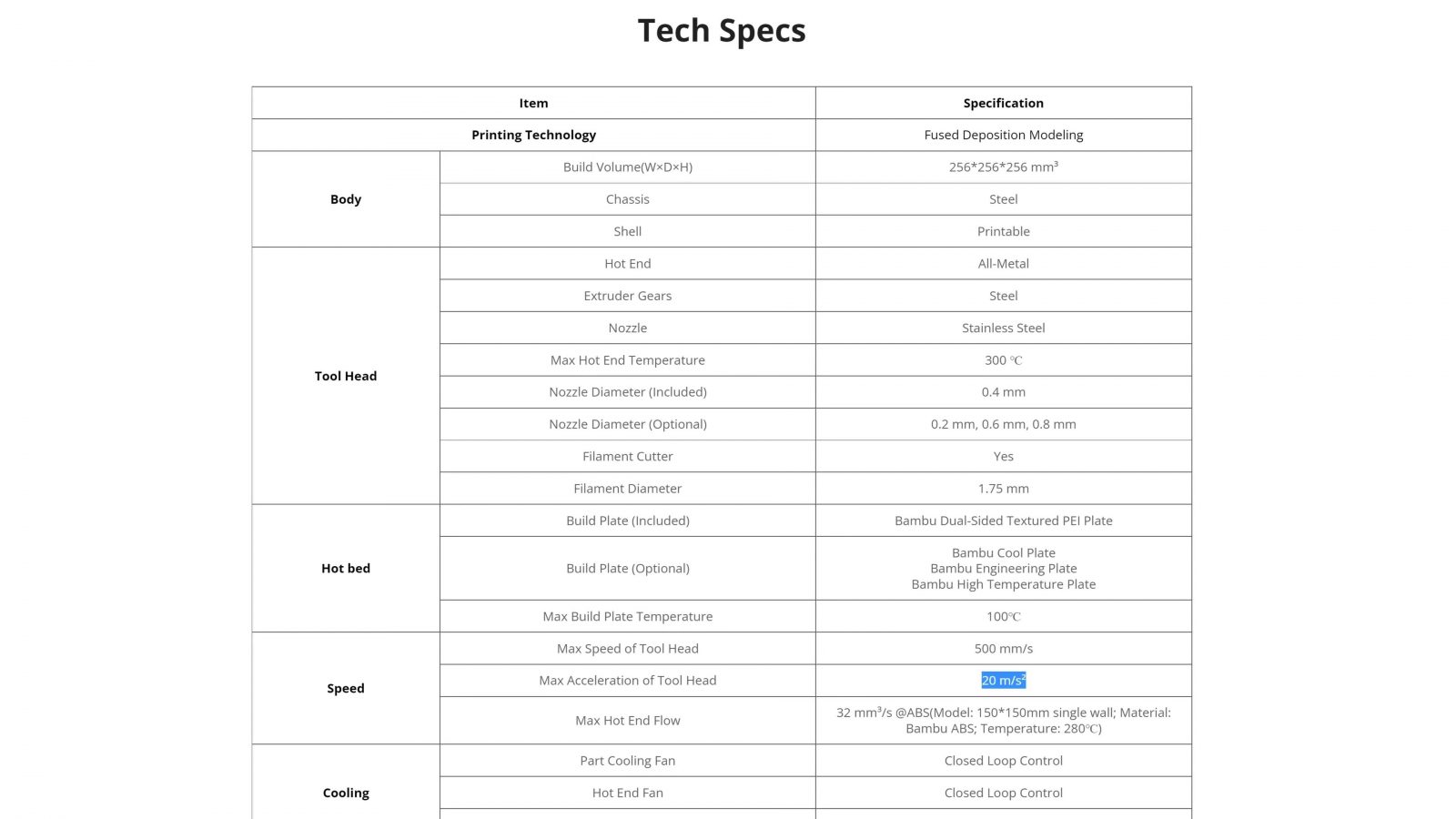

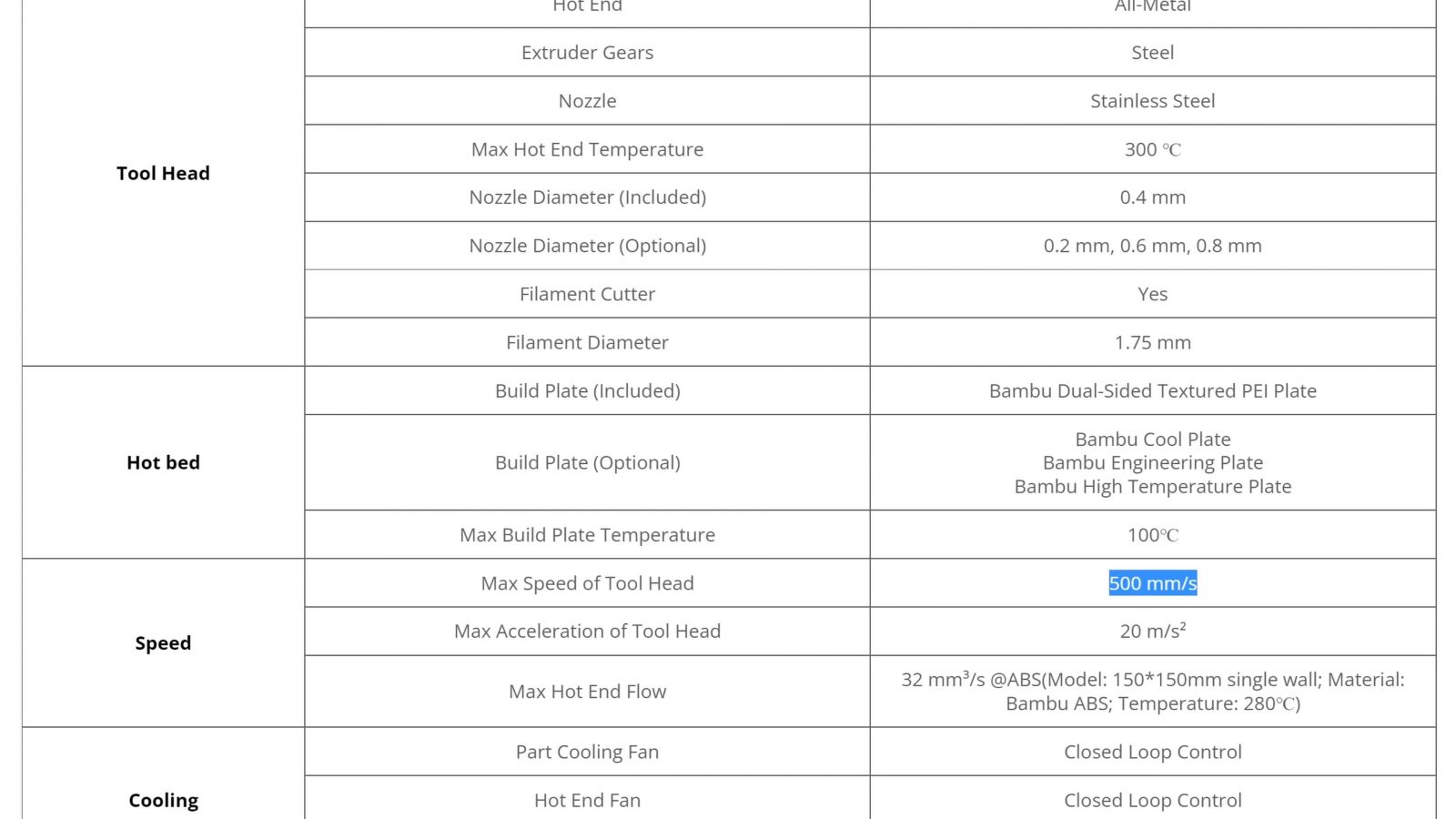

Now, the speeds that Bambu Lab list on their website, are, in what seems to be the agreement with all manufacturers who list speeds these days, completely ridiculous. They claim 20,000mm/s² in accelerations and a top speed of 500mm/s, with the hotend being able to push out 32mm³ per second, as long as it’s ABS printed at a chill 280°C. For reference, each of those figures are about 6 times as high as a “normal” printer will do with “normal” printing.

Some channels will happily tell you that it doesn’t matter when manufacturers claim completely unrealistic figures because the machine is still “fast” – but c’mon, that’s like claiming your car will do 0-62 in 2.5 seconds just because, after all, it does feel pretty zippy down low.

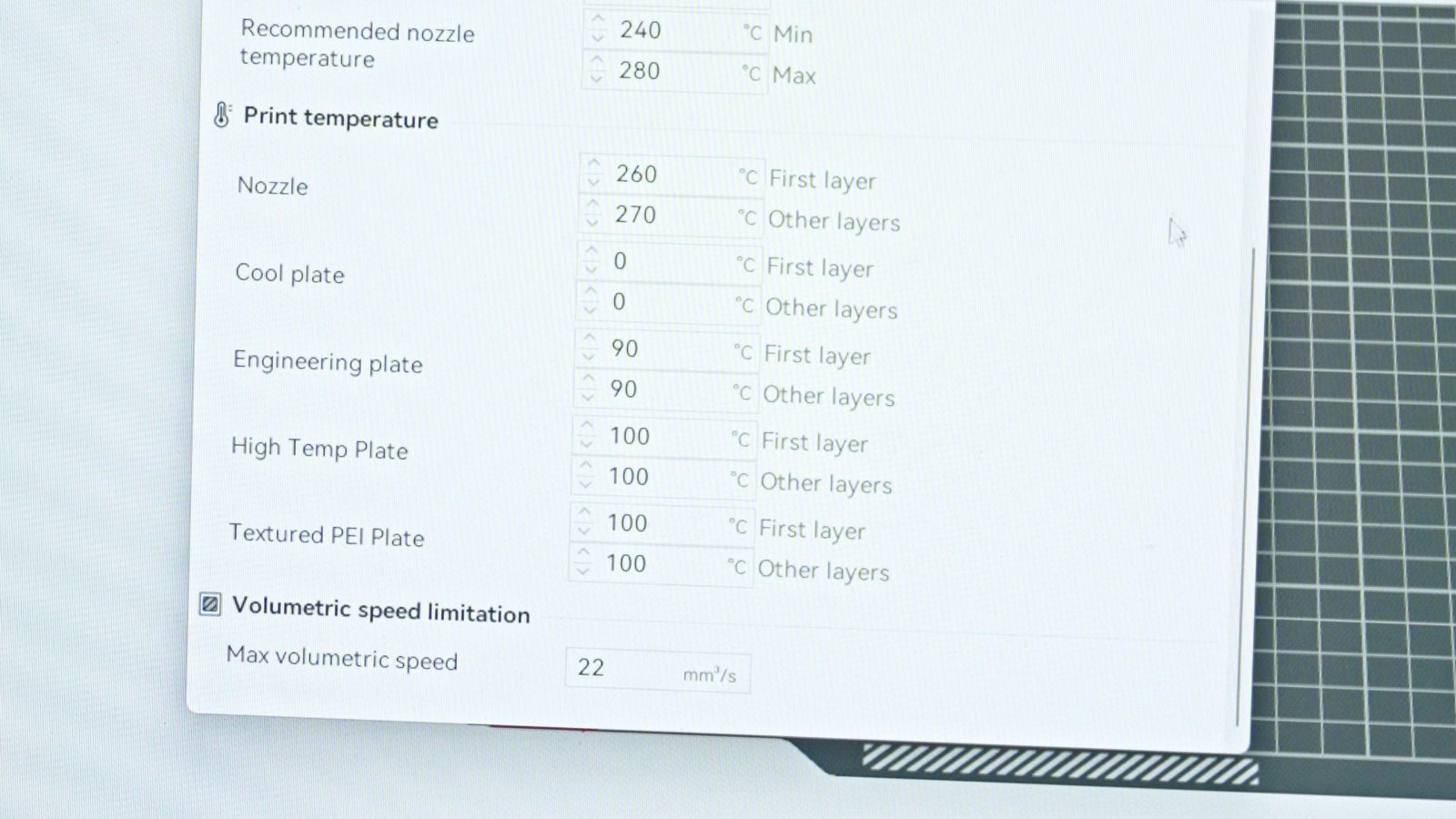

Realistically, it prints at about half the speeds they’re claiming, I mean, it’s even limiting ABS flow rate to 22mm³/s instead of the claimed 32, but you’ll still get a 2 to 3x print speed increase over a typical bedslinger while still getting good quality.

Top solid surfaces look a bit rougher than what you might be used to, but as far as ringing or detail loss with the higher speeds, there really isn’t any of that.

In fact, the details look better and sharper than on any of my other printers. It does an input shaping calibration before every print, and because it’s generating quite some force as it zips around, it is pretty noisy when printing. Mine also sounds like bits and bobs of the printer are also rattling around – and that’s probably because they are.

When it´s not printing though, in standby it also emits a pretty annoying 50kHz noise which I can hear, but maybe you are not able to.

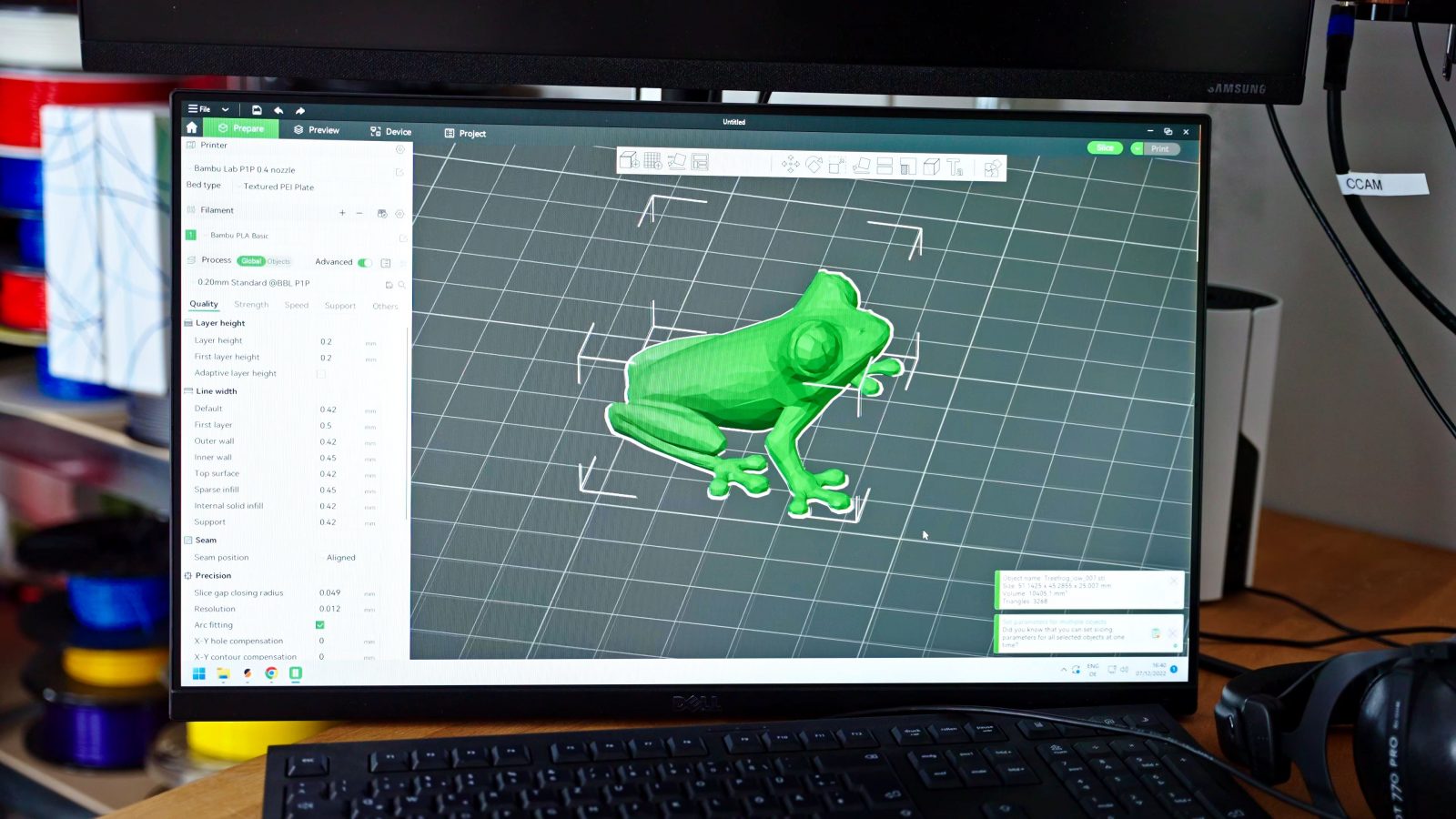

For software, they’ve made some good decisions. The firmware on the printer, supposedly, is completely proprietary, but it makes use of many of the concepts that were developed by the open-source community, like pressure advance, input shaping, and all the other stuff that’s needed to make a printer go fast.

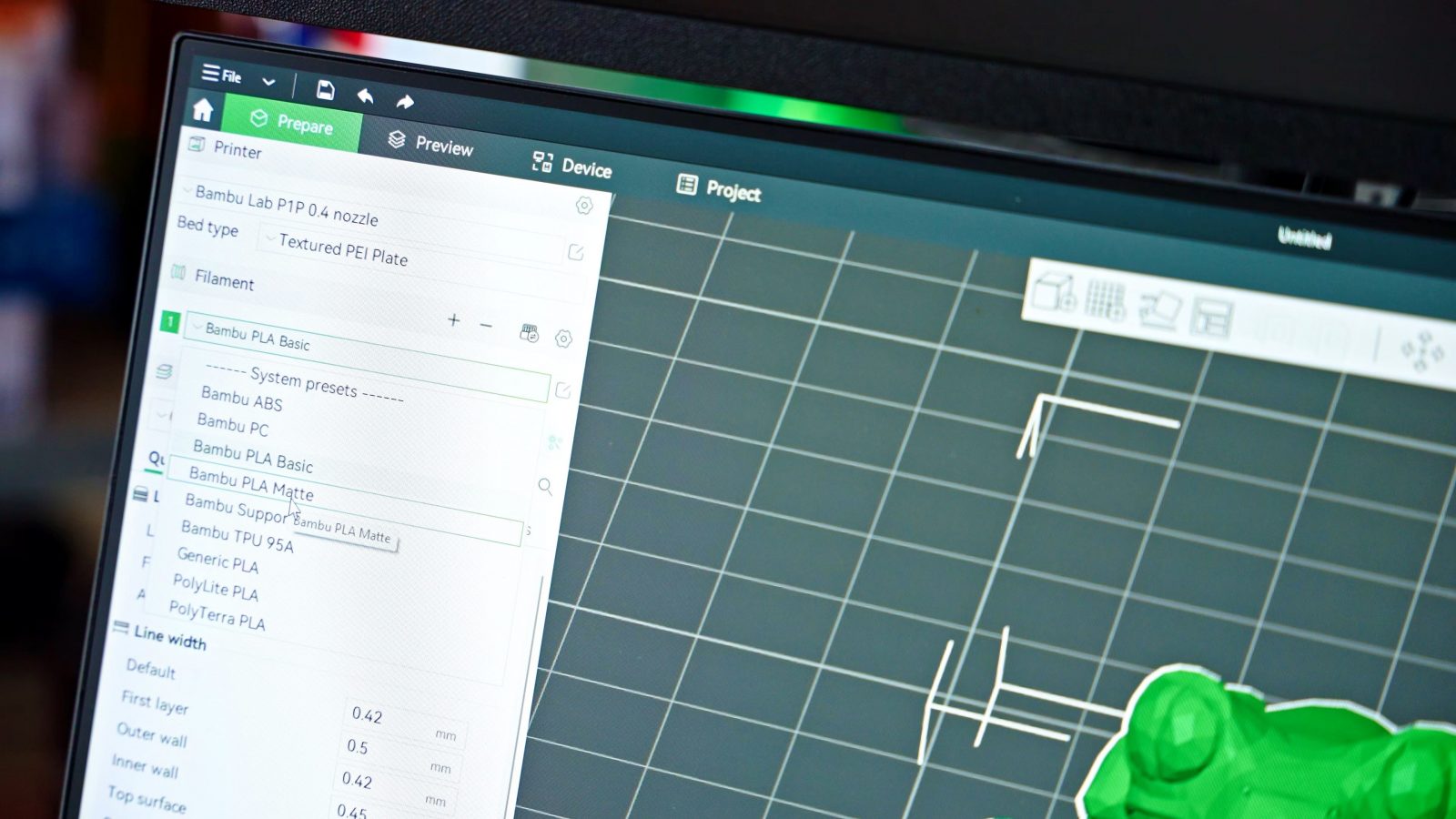

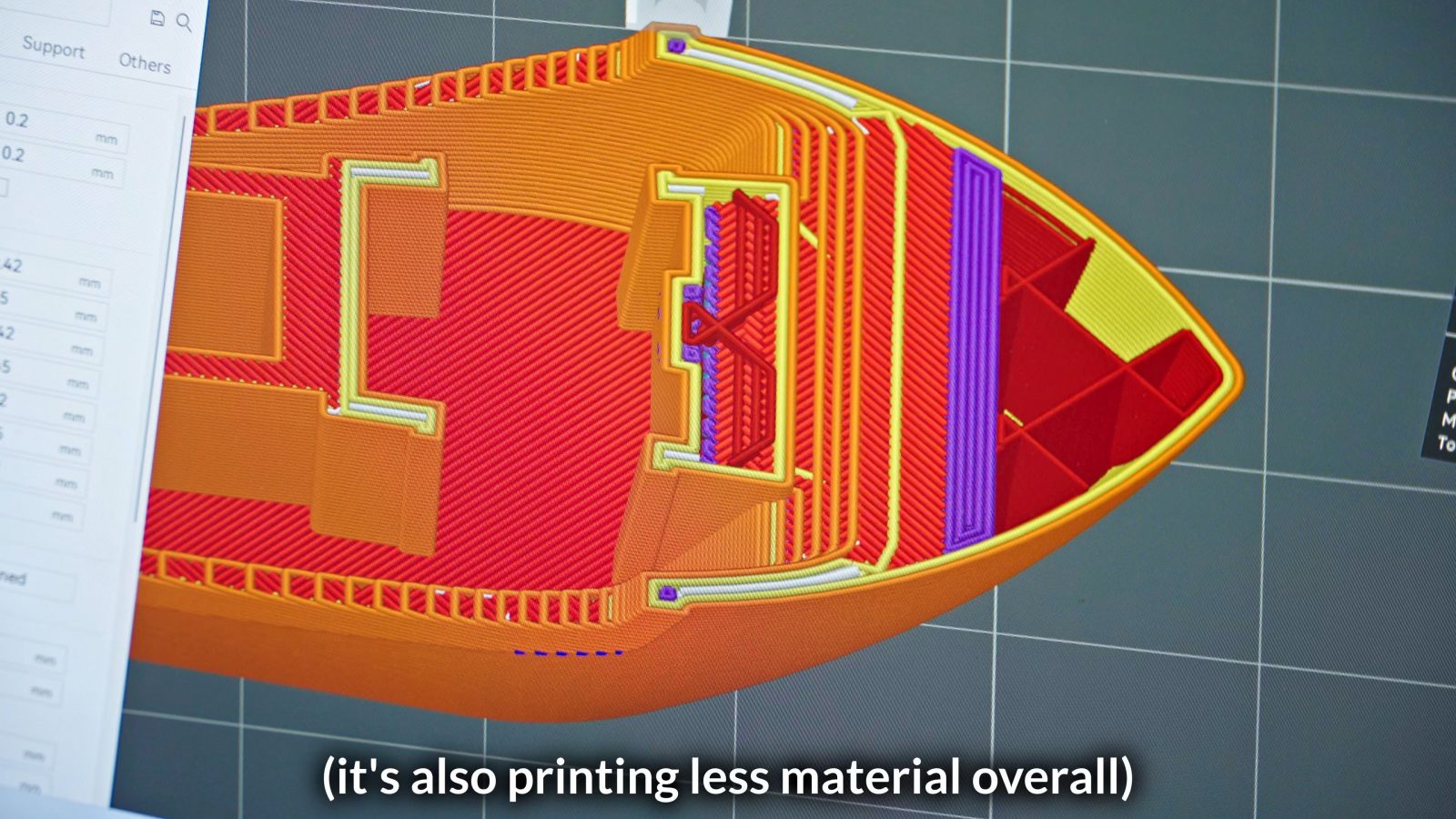

For the slicer, they’re using a modified version of PrusaSlicer with plenty of tuned presets for their machines – a huge plus. But here, also, the settings are tweaked for speed. Basic straight-line grid infill is the new default, and many of the sections that used to be printed as little back-and-forth squiggly lines to grab onto sparse infill better are now just straight lines, and that does matter a lot more when you’re trying to get up to higher speeds.

Of course, there’s networking built in, so you can send files straight from your slicer to the printer – which is super convenient, but just like with releasing the code they based on previous open-source work, here, also, Bambu Lab had to be poked with a mini-shitstorm to take some measures to implement basic security features for the data they’re sending over the network and over the internet.

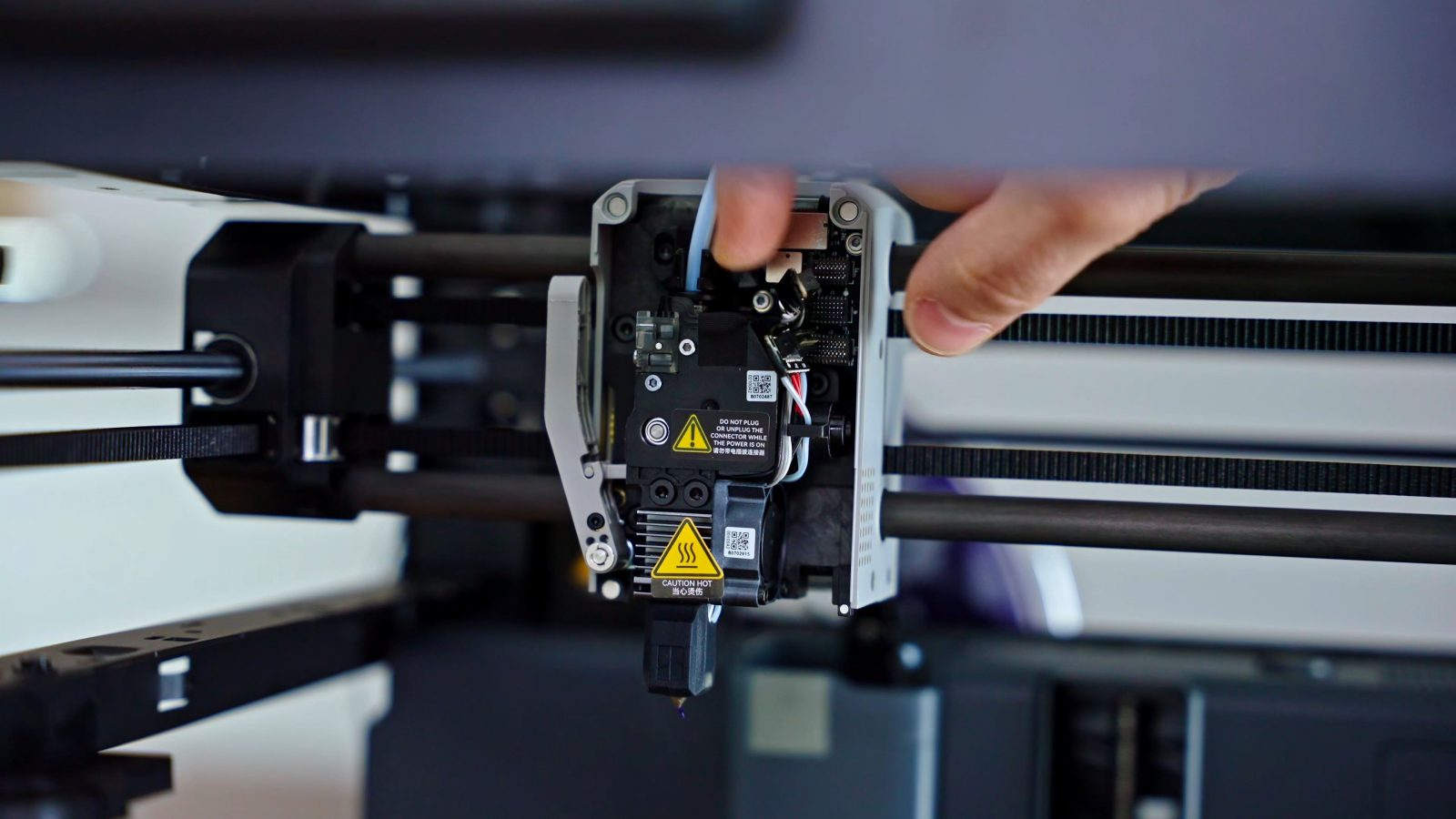

Now, what I was wondering the entire time when looking at the differences between the P1P and the X1 and X1 Carbon that it’s stripped down from, is whether the changes introduced with the P1P are really there to save cost or whether they’ve more of a means to make the P1P worse than it actually needs to be – to differentiate it from the more expensive X1 series and to protect the market for that.

I mean, just look at it – it’s like someone took a ready-built gaming PC, tossed all the panels, and ripped out some fans. This thing looks incredibly bare-bones, and frankly, flimsy, without the, arguably, decorative shell. Of course, the X1 series is completely enclosed, but would it have hurt to add at least some shells around the corners? Yes, you can print panels yourself, but now we’re starting to slide into the “an Ender-3 is the best printer, you just need these 23 simple mods” territory.

On the X1 series, there is basically a touchscreen Android phone stuck to the front of the printer, which, to my understanding, handles not just the user interface, but also the networking, camera, and print failure detection.

And they replaced it with a low-resolution, poor viewing angle, monochromatic screen, and the buttons from an Anet A8. This just feels like such an unnecessary downgrade. Sure, I get that including an Android device is going to add cost, but couldn’t they have used something like the screen from the Ender-3 v2 instead of going all the way to the bargain bin? And that’s on a printer that is less than 1/3rd the price of the P1P.

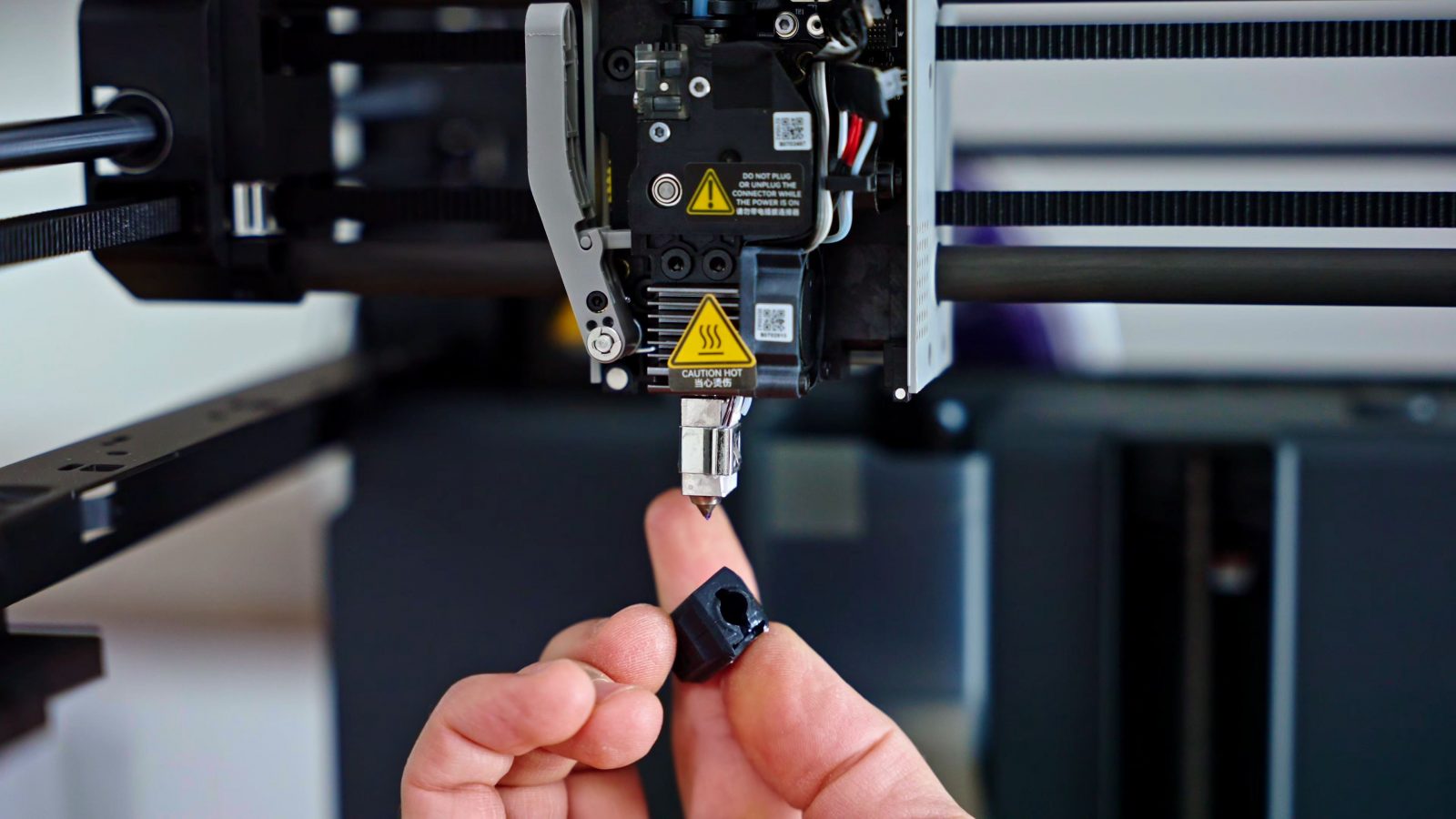

They’re also not including a hardened nozzle on the P1P, even though it costs the same as the included “stainless” steel one.

But the P1P is also getting some upgrades over the X1 series – it’s the first printer from Bambu Lab that uses a coated, textured PEI sheet. Yet there is now a lower bed temperature of just 100°C, which seems unnecessary. And for that hotend, apparently, it’s an upgraded version over the one from the X1 which seems to have had a weak point in the connector used. So it’s already making the X1 obsolete in some way.

So the question is – what would you like to see tested for the full review?

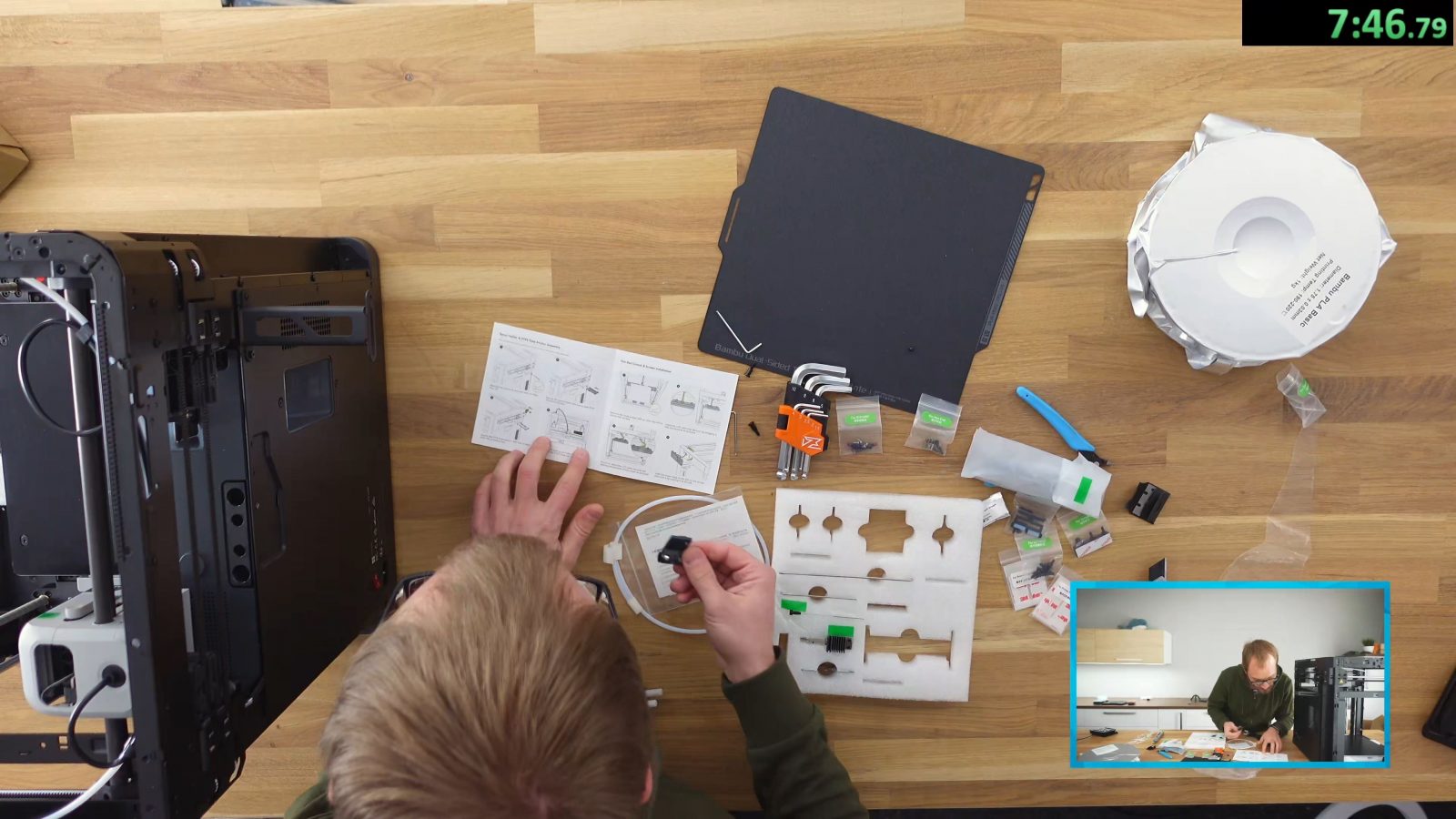

Should I go hard on print speed, compare real output quality vs the speed gains, or just do the full upgrade-a-thon that they’re suggesting with printing your own panels, adding adapters to accept an AMS and installing the massive secondary part cooling fan, LED lights and the camera that you only get included for free if you preorder?

And if you want to see the full unboxing of this machine, including me trying to speedrun to the first print in the 15 minutes that Bambu Lab suggests, you can check that out over on the “More Layers” channel.

In either case, thanks for watching, keep on making, and I’ll see you in the next one.

Models shown:

💙 Enjoying the videos? Support my work on Patreon!

Product links are affiliate links – I may earn a commission on qualifying purchases (at no extra cost to you)

Check out my second channel “More Layers” on YouTube for livestreams