A few weeks ago, Hackaday posted an article saying that 3D printing was still way too hard to get into and that finding the knowledge that everyone seems to be taking for granted these days can be kinda hard to piece together. So that’s what I’m going to fix with this video series.

Welcome to the basics course on 3D printing!

- What is a 3D printer?

- Choosing a machine

- Resin printers

- Filament printer parts and maintenance

- Acquiring print files

- Basic slicer settings

- Whole 3D printing process

- Requirements for 3D printing

- Common issues

- Where to go from here

The Episodes

We’ve got 10 episodes coming up that will help you understand how 3D printers works, what the fancy terminology means everyone’s throwing around, what to look for in a machine if you’re considering getting one yourself, and, of course, how the printing process works. If you’ve heard of 3D printing and are maybe thinking about getting a machine for yourself or have already picked one up, then this series is for you. But if you’ve already gotten started, I think you’ll still get some good info out of it.

This series is free for everyone to watch, there’s no paywall, this isn’t a free sample for a longer course I’m trying to sell you somewhere, this entire thing is just up here on YouTube. It’s the biggest video project I’ve worked on and I want to thank all of you who are subscribed to the channel or are even supporting my work directly through Patreon or YouTube memberships, without you, I wouldn’t be able to produce this series and just put it up on YouTube. And also, we’ve got a few partners onboard for the series, they have been providing materials and sponsorships, so thank you to all the companies supporting this project as well, you’ll hear more about them as we move on.

One note for the entire series:

Instead of doing a boring lecture-like approach, I’m instead focusing on one subject for each video – that means, you can watch them out of order and just focus on the bits you’re interested in, but you can also jump to other video explaining some bits in more detail if we’re moving at a pace that’s a bit too fast for you. So, let’s get into it.

Okay, let’s get started with the most basic thing of all:

What is a 3D printer?

I just want to make sure we’re all talking about the same thing here. The textbook – Wikipedia – says it’s a machine that produces three-dimensional parts using an additive, layer-based process. That makes a lot of sense – to me.

So, let me break it down, three things in here that really define what is a 3D printer and what is not:

- Three-dimensional

- additive

- layer-based

“Three-dimensional” means that you can make parts that are more than just a flat geometry. If you have a 2D printer, you’re adding ink or toner onto a perfectly flat sheet of paper; and cutting out contours from flat material like paper, aluminum or plastic gives you, technically, a part with some thickness, but it’s still only got that 2D shape, but now a bit thicker. A 3D printer can also make those flat parts, but its unique feature is that it can have details practically anywhere on a part, in any orientation. This is how these parts came off the printer, and that’s the three-dimensional part.

Next, “additive”. If you want to make anything, really, there are two basic ways of creating it. Additive and subtractive. Let’s say you want to bake cupcakes, what you do is you start with an empty bowl and add in your ingredients, one by one, until you have your finished batter. That’s an additive process. What you could also do is to buy a cake and then cut away everything that doesn’t look like a cupcake. Also works, but I don’t think that’s how you typically make cupcakes. That would be a subtractive process, you start with something larger than what you need and remove everything that’s in the way.

The subtractive equivalent for making 3D parts would be something like manual wood carving or CNC milling or laser cutting, where you shave away at your material stock until only your finished part is left. But 3D printing is additive: The two common ways of printing parts that are relevant for the machines you are most certainly going to be looking at are either filament- or resin-based, where the machine takes your raw material and, for example for filament printers, melts it down and uses that to add on material until what you have looks like the part you want.

And that brings us to the last part, “layers”. Now, there are some approaches in 3D printing that blur the lines of whether that process is actually using layers or not, but generally, a 3D printing process will slice a model into fine layers and then print those ones on top of the other, from the bottom up. The printer knows very little about what it’s actually printing, and at most, it’s only seeing parts of a single, two-dimensional layer at a time. For a filament machine, it’s getting all the paths along which it needs to lay down material in each layer, then it moves up a bit and starts working on a fresh set of moves for this new layer that it’s now printing on top of the old one. Resin machines are similar, but the common ones actually project light into the resin tank, which cures the resin in all the spots where you want to end up with a part and block out the light anywhere where there should be no cured material in the final part at all.

We’ll have a closer look at resin printers in episode 3 of this series, they’re a great type of machine for special applications, but I think starting on a filament-based machine is a way better choice. The parts can still be very detailed, but the process is much safer, less messy and it’s an approach you can actually watch while it’s happening instead of looking into a black box and then miraculously having a part appear a few hours later.

Want a few examples?

Cool. The Prusa Mini: Makes three-dimensional parts, check. Additive process, check. Layers, check. This is a 3D printer.

Resin printers, like the SL1 or Mars: Check, check, check.

Cupcake decorating: Uhm, I guess it’s three-dimensional, though really it’s just a single 2D layer you lay down, Additive, yes; layers, definitely. So I guess, kind of a 3D printer? But typically, it’s a machine controlling the process, not a human.

A “3D laser printer” – commonly known as a lasercutter. Three-dimensional: Nope. Additive: Nope. Layers: Nope. Who exactly had the idea of calling these “3D laser printers”?

An injection molding machine does make 3D parts, but it’s lacking the “layer” component, and 2D, like, paper printers are missing the “three-dimensional” part, obviously.

Ok, so I think we’re on the same page when it come to what sort of machines we’re actually talking about. So what do we use them for?

Tool or Hobby

This is, I think, one of the most important bits when it comes to how you look at 3D printers. Of course, you’ve all seen the trinkets and flower pots and pretty things you can just download and print, and if that’s all you want to use a 3D printer for, that’s fine! But as we’ve recently seen with printed faceshield brackets for healthcare workers, 3D printers are able to make parts that are more than just nice to look at. With how capable and just, you know, ready to perform at any time even the simpler machines have become, I think we’re at that point where we can really look at a 3D printer just like at any other tool, like, I don’t know, a Skilsaw or something, where it’s really less about the machine itself, but more about being able to use it well enough and then making use of that machine, with the nitty-gritty details of the process itself kind of getting out of the way. You don’t need to know to wind the motor coils in a skilsaw or how to engineer the bearing in order to be able to make a good cut with it.

Much of what I try to do here on the channel is making use of 3D printers and other sorts of digital fabrication tools as just that – a tool.

But that’s not to say that getting into 3D printing as a hobby and because you’re interested in the tech and how it all works together, that that wouldn’t be a legitimate use. It’s just a different one, and going into 3D printing, you should be very aware of whether you’re looking for a tool or a hobby.

And actually, one really cool thing you can do with 3D printers is making more 3D printers. Yeah, yeah, I know, that a bit of a meme, but that’s actually how this all got started.

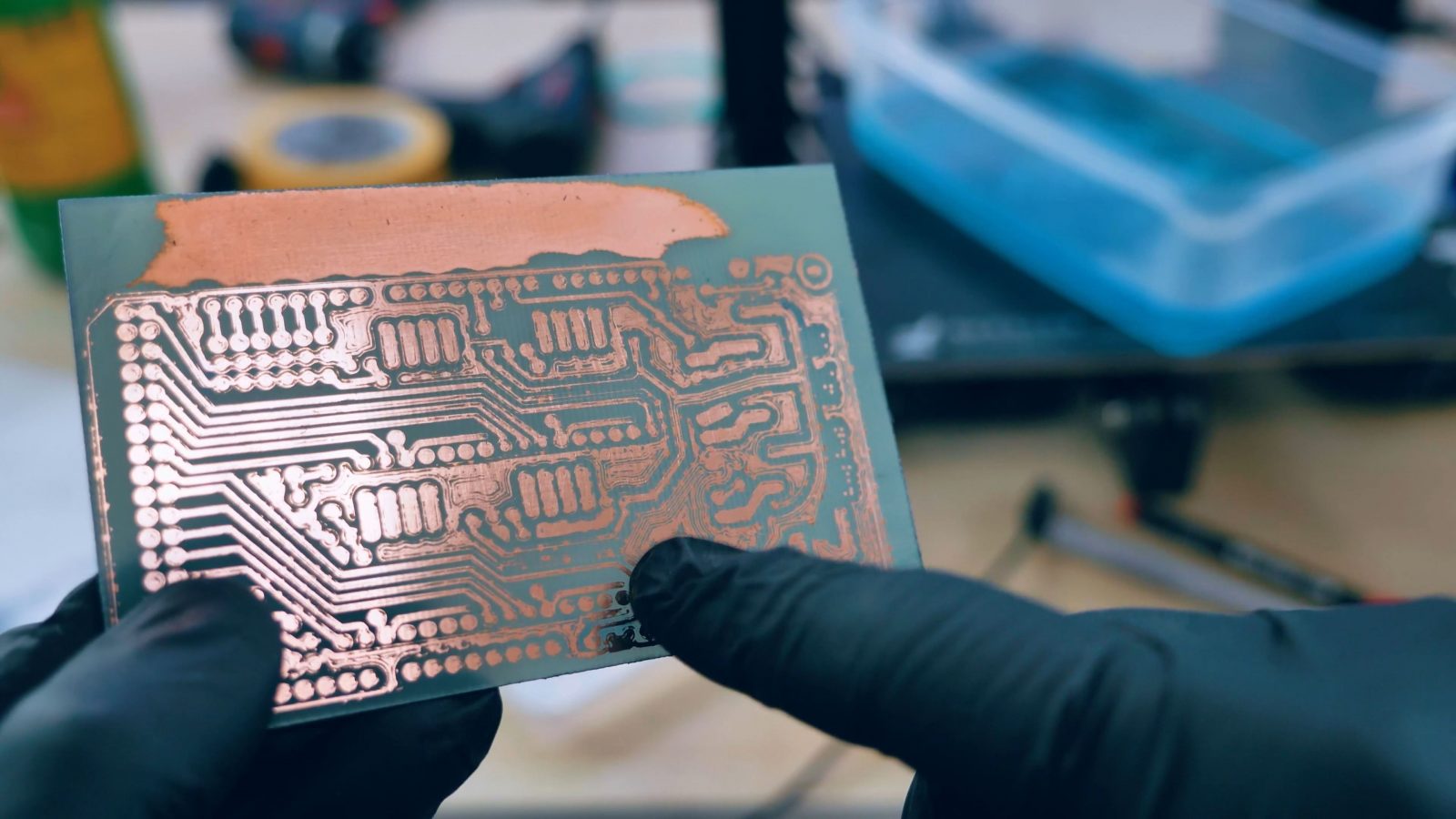

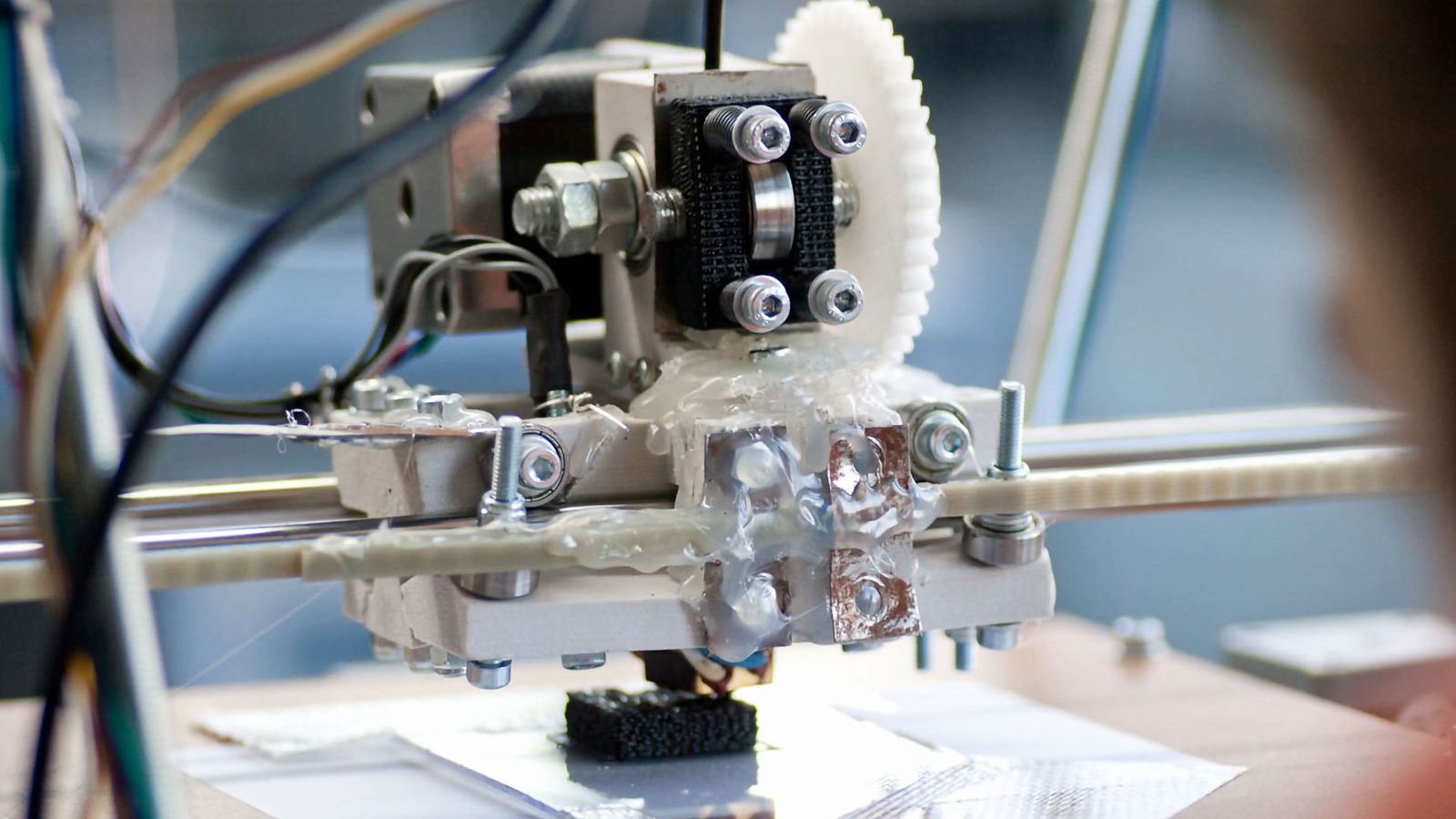

In fact, if you look at these two machines, you can still see that they’re also made of 3D printed parts. Some people prefer designs that make use of bent sheet metal and injection molded plastic instead, but I think having at least a few 3D printed parts is actually a good thing for a printer. The first machines of this style were called “RepRap’s”, and their goal was actually to manufacture as many parts for the next iteration of printers on the current machines they had, and then using common material for everything that couldn’t be printed. So of course, the printed parts would include all these frame parts, but also, circuit boards using markers to draw on the traces, printed pulleys for the belts, there are even projects that print the stepper motors that drive these machines, or just the entire printer frame.

And that allowed these machines to progress from expensive, complicated monstrosities to machines that cost maybe a fifth of what the first ones cost and are much more capable and reliable – in not even 10 years.

I built one of the early ones, and it was pretty rough.

The other part to why these machines were able to progress so fast is because so many people are sharing the effort they put into improving the designs as open-source, so that everyone else would be able to learn from what they did, and if anyone like a specific design, they would be able to simply use that previous work for their own designs. These two printers and a bunch of others are open-source, which means anyone can grab a copy of the mechanical design files, the software that runs on the printer, electronics designs, everything is available for others to use and learn from.

Unfortunately, we’re seeing more and more closed-source designs that not only make it harder to see how the features of that machine were created, but it also makes it harder for the community to work on those machines and share improvements with everyone else. That’s kind of a dead-end, just like when a manufacturer just grabs open-source software, uses it for their purpose, claims they’re “powered by open-source”, but then doesn’t share back what they did. But going into detail on that would be way too much for this video, it’s just something you should be aware of to understand what got 3D this far.

So, let’s recap!

A 3D printer makes parts by adding material in layers, and what it makes is entirely dependent on what instructions your software sends it. That’s both true for filament and resin printers. And lastly, we have these machines because their designs and ideas got shared freely as open-source and then improved on, and I think that’s still something that’s worth having, even today.

So in the next video, we’re going to go through what you should be looking for in a 3D printer and what to avoid. You can check that video out here, until then, thank you for watching, make sure to get subscribed, keep on making, and I’ll see you later.

💙 Enjoying the videos? Support my work on Patreon!

Product links are affiliate links – I may earn a commission on qualifying purchases (at no extra cost to you)

Check out my second channel “More Layers” on YouTube for livestreams