Wow, we’re already at the last video of this series… I’ve produced these over the course of almost two months, and yeah, it has been crazy. I’ve got to get used to a routine again that isn’t “eat, sleep, produce, repeat”, and you’re probably wondering what should be the next steps for you. Do you really need to buy your own machine? How should you go about starting to use it productively instead of getting stuck in “novelty” phase? Yeah, let’s looks at that today!

So where do you go from here? Great question, but that really depends on you. I’ve tried to stress in this series that you should think about what you’re going to do with a 3D printer before you grab one. Now, I know usually 101 or “basics” series have an “examples” section where they just go through the things we just learned and apply it to a “real”, fake project, but you know, there are plenty of videos or writeups on my channels and on others that are either full-on 3D printing projects or just make use of 3D printing where it makes sense.

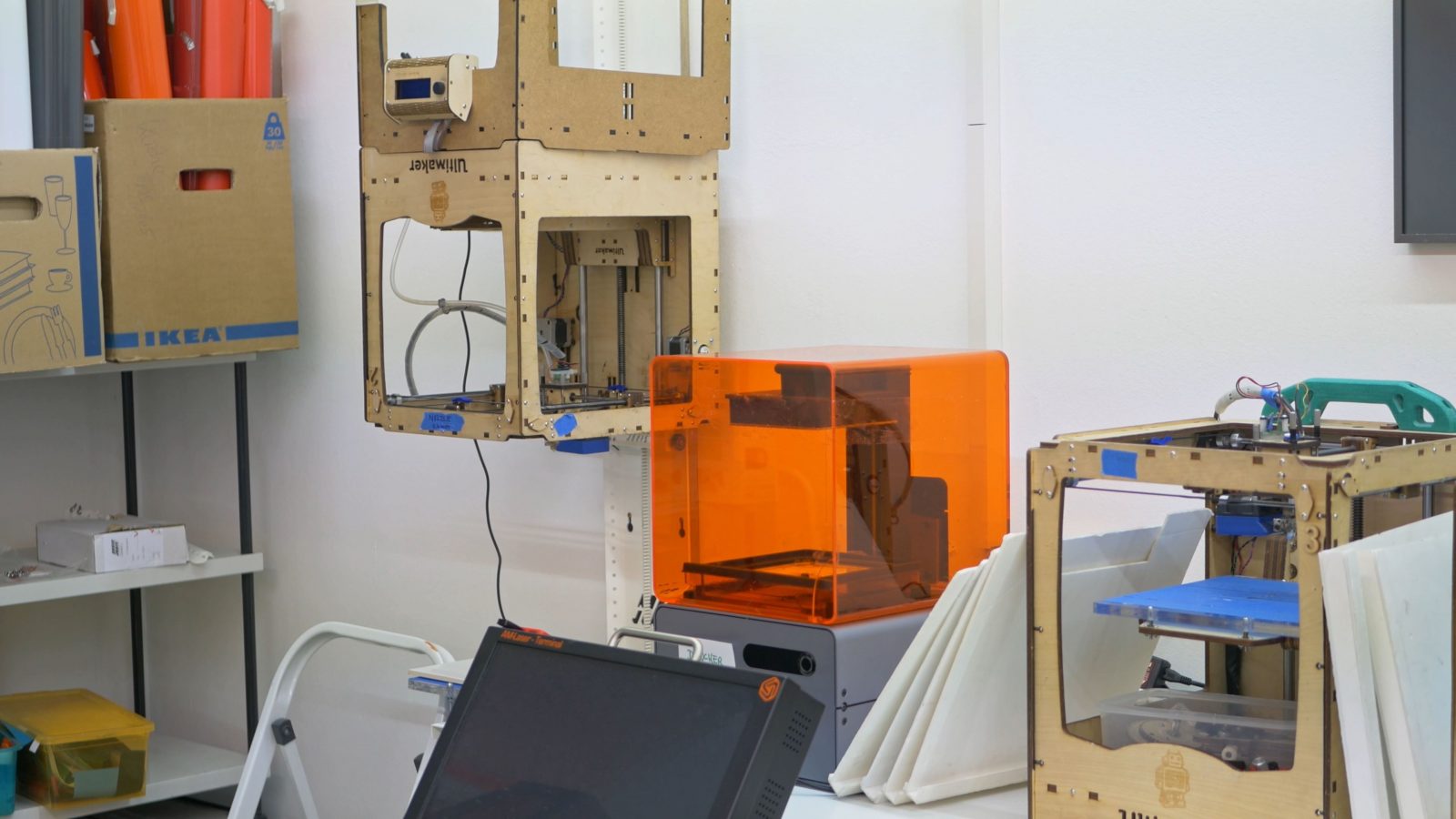

If you’re unsure about whether a 3D printer is the right tool for you, maybe check out your local makerspace first.

Right now, a lot of them are still closed, unfortunately, but maybe you’re watching this video a year after I uploaded it in what is now July 2020 and maybe things are different by then. Or maybe not. I don’t know.

Anyway, having a “known good” machine that you can try printing your ideas on is really valuable and you’ll get a much better feel for what’s doable and what actually printing something entails than what I can show you on video.

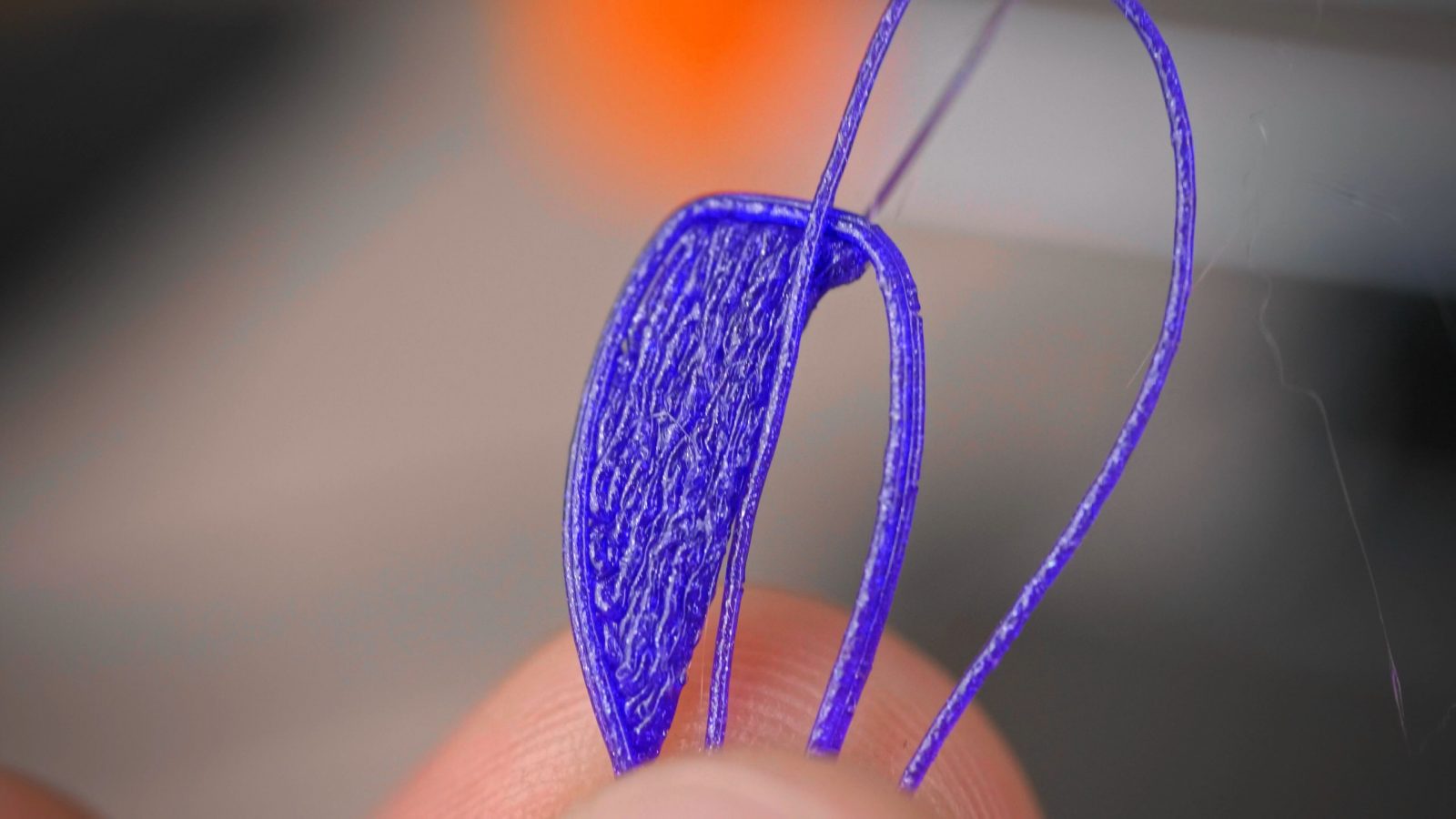

Whatever you do, start small. Pick a small project or a simple design to get going on, and just take things one step at a time

And that can be as small or as insignificant as this little piece. This is an adapter my mom needed so that she can directly set her coffee filter onto her mug in the morning. Perfect for making just one mug of coffee!

You know, stuff like that, useful, not too much of a time investment if it doesn’t work out, but still with plenty of learning opportunities along the way. For example, for this to be dishwasher safe, I printed it out of PC-ABS, because PLA is obviously just going to warp.

And with those learning opportunities comes the temptation to start upgrading things. My suggestion: Try to understand what is going on first before you dive into a potentially frustrating and costly upgrade bonanza. Sometimes just a better slicer profile can make heaps of a difference for print quality and reliability.

What I also always find super useful is being able to print different materials. PLA is totally fine for a lot of things, but knowing how to print with PETG, ABS, Polycarbonate, and maybe flexibles and Nylon really expands what you can do with that same skill set of knowing how to print parts. When trying a new type of material, start with a known-good filament first, so that you can learn how it behaves and how to work with it without having to worry about the material just being bad. And once you’ve figured out how to print it, you can then always step down to a cheaper brand if you want to and if you run into problems with that, you’ll know whether it’s bad filament or just an an inherent shortcoming of the type of material you’re using.

Once you’re comfortable with your machine, there are plenty of good causes that you can use your 3D printer for. For example, in the early months of the Covid-19 outbreak, there’s been a huge demand for printed faceshield, in fact just the small headbands that you clip an easily available transparency sheet to. That has worked fantastically well in places where regular supply chains just weren’t able to keep up, so I guess you can expect a lot more like that in the future, now that we, as a 3D printing community, have proven that yes, these machines are able to make real, functional parts, fast, and that people are able to self-organize to make it happen. So, thank you to everyone who has contributed to that cause.

If you want a big project, there’s e-nable that you could join, printing low-cost prosthetic limbs, but you know, even just helping out friends and family and printing the little nick-nags they need is, I think, something that already makes the world a tiny bit better.

Let’s check out some of my subscriber’s comments and questions from the rest of the series!

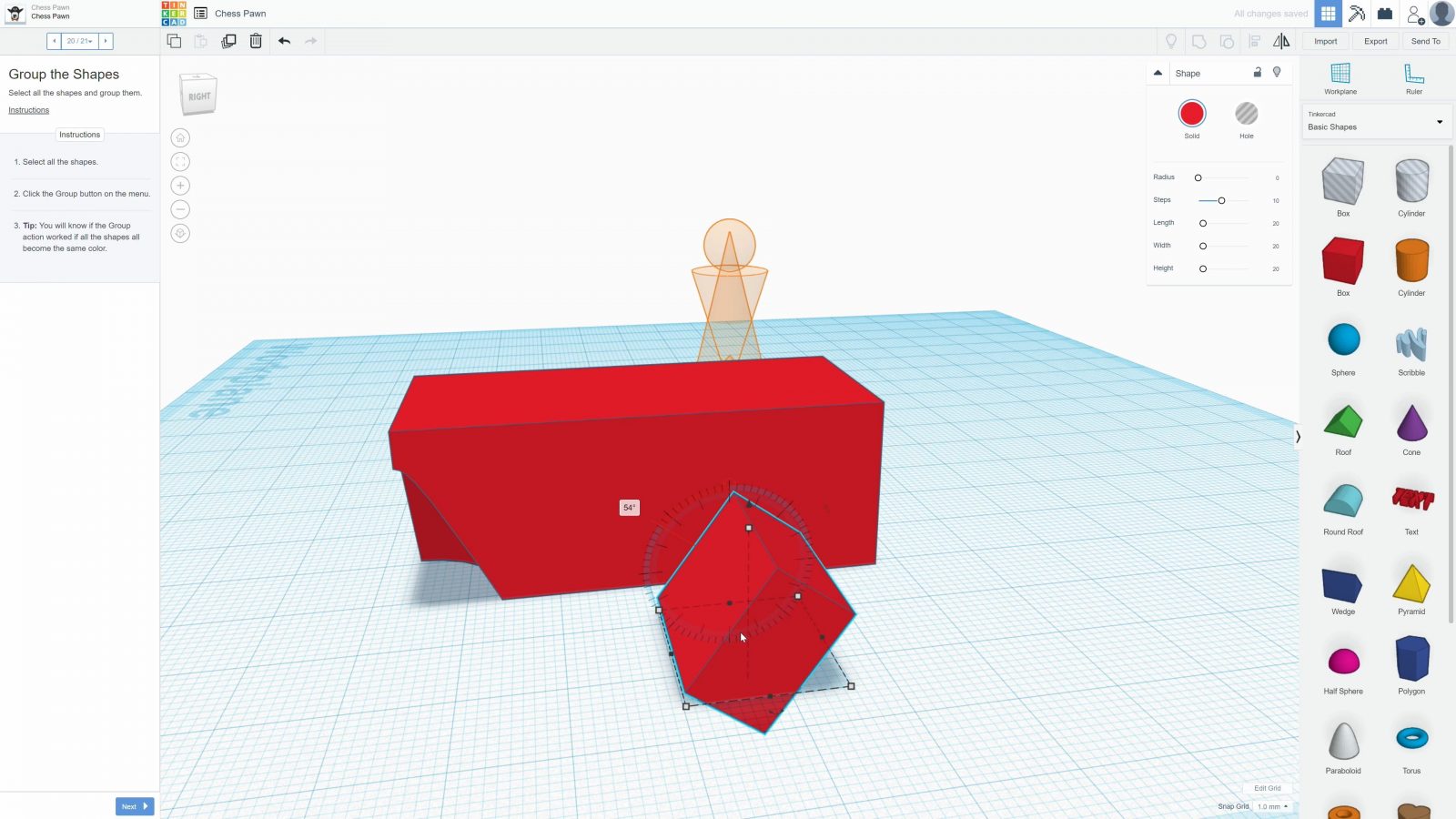

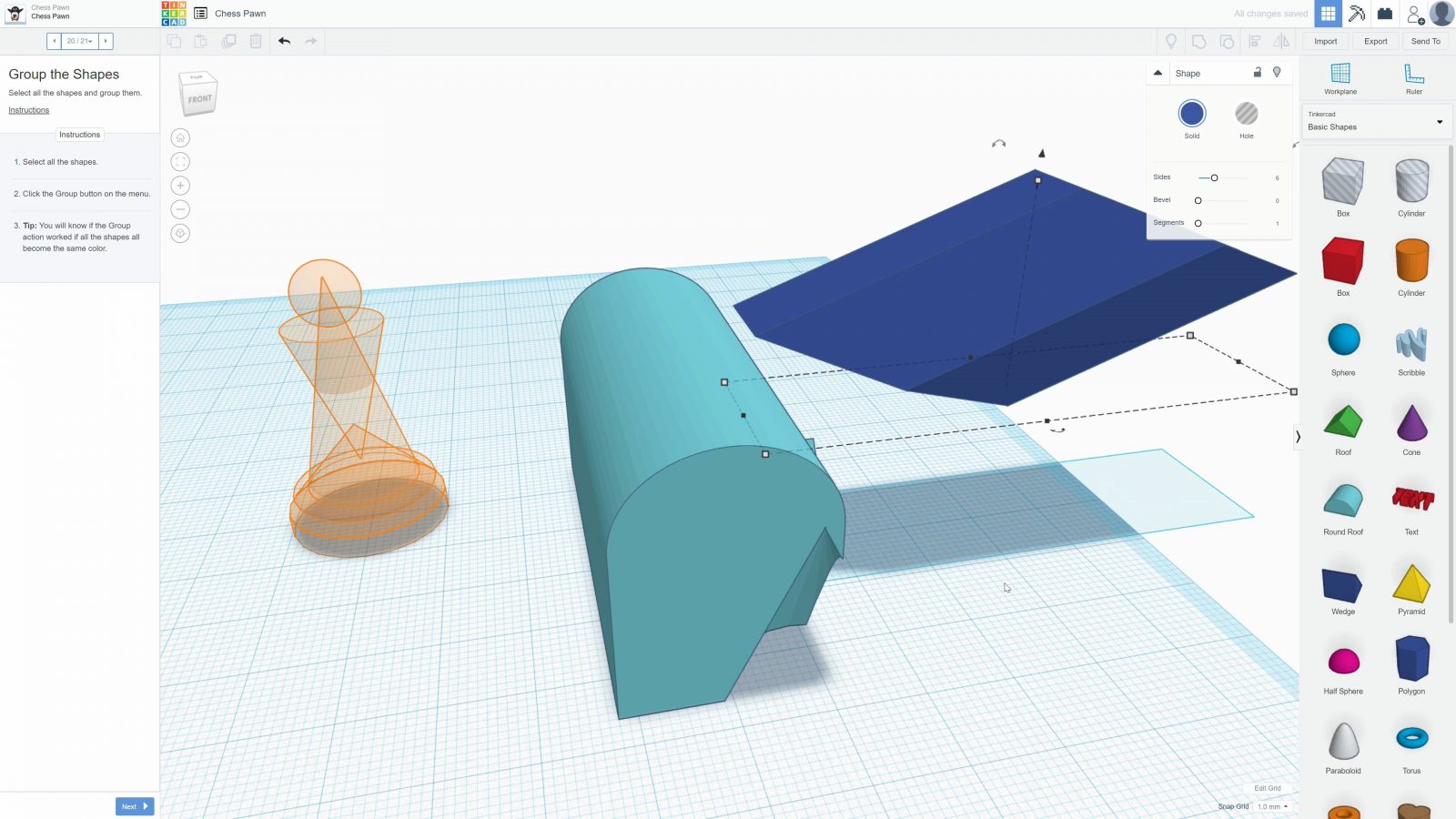

Mario is saying “great content, please don’t forget Tinkercad!”: Yes, you’re totally right, I should have mentioned that. Autodesk used to have a lot more “simple” tools, like 123D Design, which was a Fusion360 “light” version, basically, but all those 123D tools are now gone, but Tinkercad survived! So Tinkercad is a really simple, I guess actually “playful” way of designing 3D parts.

It’s all about starting with a few basic shapes and combining those with each other, cutting away bits, adding bits here and there. It’s not the most powerful tool in the world, but it’s definitely an easy start if you or your kids have never used a CAD tool before. So definitely, Tinkercad is worth a look. It’s free and I guess Autodesk are seeing it as a “soft introduction” to eventually sell you a subscription to their bigger products.

Adam is asking “should I use a 0.45mm first layer height on a 0.4mm nozzle and will that a loss of detail?”: I’m not a fan, unless you go really wide on your extrusion width as well, you do lose quite a bit of control over how that extruded filament sausage ends up looking, and as a rule of thumb, if you go above ¾ of your nozzle size, or I guess more accurately, of your extrusion width, your filament is going to start squirming out towards the sides and isn’t going to make great contact with the bed, so you end up with the opposite of what you’re trying to get.

Now, you’d think the extra width would be an issue with small details, but modern slicers like PrusaSlicer actually compensate for that and will fill those small spots as well.

MC is saying “Newbies should know about thermal protection!” – and yes, I totally agree, but it’s impossible to find out if the manufacturer has correctly implemented all the safety features that are needed for a reasonably safe use their printer, so definitely look at some reviews that test those features.

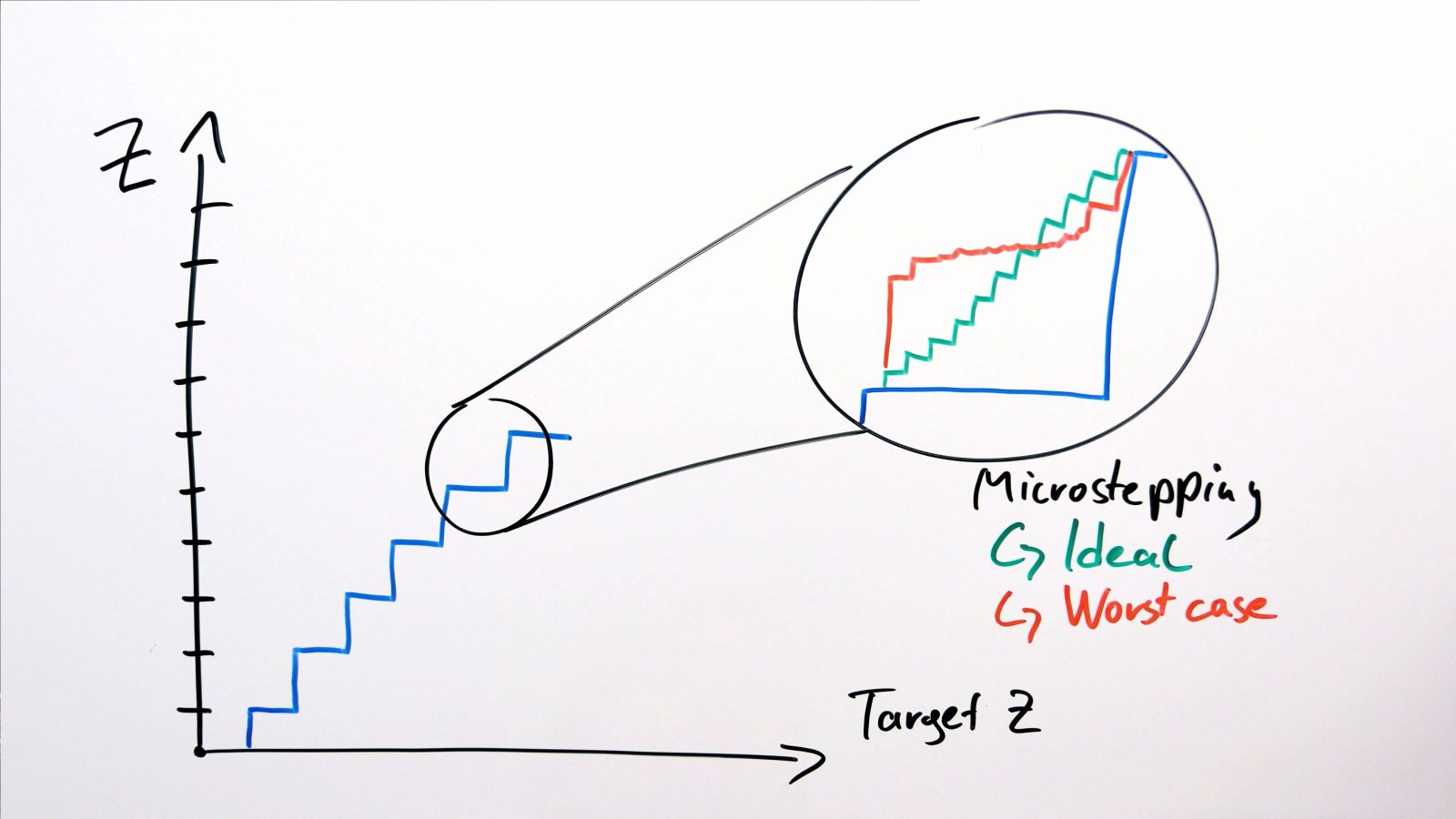

Tom is asking about the resolution of the Z-axis, which I’ve super briefly touched on in one of the videos, but basically, every axis has a “natural” step size, and on most printers, you don’t have any guarantee that the microstepping between those positions is reliable.

Now, Prusa does something where they let you calibrate that microstepping interpolation on their Trinamic drivers, but on most printers, the microstepping positions can be pretty far off. So on those, in the best case, you can only get reliable position on every half step, so with a common setup, every 0.02mm – and 0.15mm layer heights aren’t divisible by that. So yes, 0.16mm layers would be a better choice, but as soon as you introduce auto bed leveling, all that goes out the window and basically, you can use any layer height you want because you get dithering of those steps throughout the layer. But that’s a topic for another video.

Vorname wants to know where I get my shirts: On the internet! It takes a lot of scrolling to find these!

Anyway, I hope that answers some of those burning questions, and I hope this series helped you get into 3D printing – or if you already knew everything I was talking about, share it with a friend that could use the info.

A massive thank you goes out to my Patrons and YouTube members for the help with deciding which topics to cover, I’ll try to do a lot more direct voting on future video topics there. We also do Q&A Hangouts there!

And lastly, I couldn’t have taken the risk of spending the better part of two months just working on a series like this, so thank you to the sponsors that made it possible.

And thank you to you for watching! I would encourage you to get subscribed and then to comment below what you would like me to cover next. Anyways, that’s it for this series, keep on making, and I’ll see you in the next one!

💙 Enjoying the videos? Support my work on Patreon!

3D Printing Basics – Episodes

- What is a 3D printer?

- Choosing a machine

- Resin printers

- Filament printer parts and maintenance

- Acquiring print files

- Basic slicer settings

- Whole 3D printing process

- Requirements for 3D printing

- Common issues

- Where to go from here