Do you need specialty bed adhesives or is your pantry already hiding a perfectly suitable 3D printer bed coating? Let’s find out! Usually the articles here are an illustrated version of the video’s script, but this one only came together once I did the experiments. So for your convenience, here’s the summary of how each one of these materials did! Pasta Water Once dried, pasta water creates a rigid, but tacky film that adheres well to PLA and PETG Sriracha Sauce Smells awesome when warm, but doesn’t hold down 3DContinue reading

Author: tom

Slice Engineering Copperhead Review

It’s been a while since I’ve reviewed just a 3D printer hotend without also looking at the printer around it – but that’s exactly what we’re going to do today. This is the Slice Engineering Copperhead, and I think it’s the first time a company is really serious about competing against E3D’s de-factor standard v6 hotend and ecosystem ever since that came out. But the Copperhead isn’t just a single hotend, it’s actually more of a set of hotend building blocks that you can use, adapt or leave out asContinue reading

How I tune in new filaments

A couple of weeks ago I asked which topic you all would like to see covered on the channel. Clear winner – how to tune in a filament you’ve never printed with before. So, let’s go over the steps of getting practically any PLA, PETG, ABS, ASA, PC, PMMA, PA, etc filament to work and to print well, but keep in mind that specialty filaments like fiber- or wood-filled ones, super-flexibles ones or stuff like Colorfabb’s lightweight PLA will need a bit of extra attention. But honestly, once you haveContinue reading

3D Printing Basics 10 – What now?

Wow, we’re already at the last video of this series… I’ve produced these over the course of almost two months, and yeah, it has been crazy. I’ve got to get used to a routine again that isn’t “eat, sleep, produce, repeat”, and you’re probably wondering what should be the next steps for you. Do you really need to buy your own machine? How should you go about starting to use it productively instead of getting stuck in “novelty” phase? Yeah, let’s looks at that today! So where do you goContinue reading

3D Printing Basics 9 – Common Issues and Solutions

3D printing doesn’t always work perfectly. I hate to say it, but, you know, when even commodity inkjet printers still need a bit of help every now and then, I think 3D printers are actually pretty good on that front today. But, still, there are things that can go wrong due to user error, the manufacturer not doing their homework, or because of bad materials. We’re going to look at some of the most common hiccups you can run into and where to start when fixing them. I gotta tellContinue reading

3D Printing Basics 8 – Requirements

In this video, we’ll look at the things you should consider when thinking about 3D printing something – can you even print the part you want to make, what should your environment look like where you print stuff and what do you need for equipment and tools to work with the machine and the final prints. What can you print? Okay, let’s get right into it and start with the models themselves. Over the years, 3D printers have become a lot better when it comes to what they can andContinue reading

3D Printing Basics 7 – What printing looks like

Okay, so in the Hackaday article that got me to do this series in the first place, one of their first questions they want to be answered is “What does the actual workflow of 3D printing look like? What happens from beginning to end?” So that’s what we’re going to look at today – the full process of going from wanting to print something to having a physical, usable part. 3D Model The thing the actual 3D printing process starts out with is a 3D model. Last week in episodeContinue reading

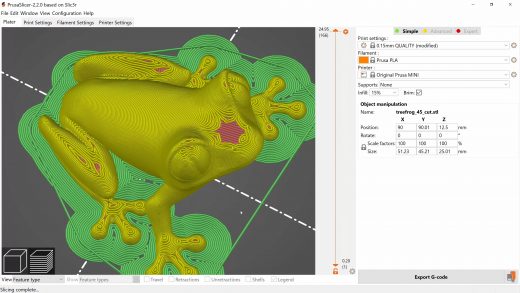

3D Printing Basics 6 – Basic slicer settings and what they do

The slicer. A mythical piece of software that decides the fate of your every 3D print. To tame it, you must first learn its language and appease the demons that live within. Today we’re going to go over the common settings you might want to adjust to get better prints out of your filament printers! So for this video, I’m going to be using Prusa Slicer, even though the name doesn’t suggest it, it actually works for any filament printer that accepts standard g-code, which means basically every relevant machine.Continue reading