What I’ve been up to last week was trying to find out how much and how quickly filament absorbs water and what the results of that are. While there’s no question that filaments like PA, Nylons, as well as PVA, absolutely need to be kept in a moisture-controlled storage solution, with the more common stuff like PLA or PETG, it’s not that clear. Sure, PETG does absorb some moisture and you’ll get some extra stringing, but how bad could it be, and is PLA just generally fine to be kept out in the open. That’s some of the things that I tried to find out, by exposing filaments to different grades of humidity and running some tests. And not everything went exactly as expected.

So in this video, I’ll be trying to get a feel for how much there really is to filament absorbing moisture. I’ve got a lot of open filament up on shelves in here, but I tell myself the dehumidifier will keep things in check and I shouldn’t worry about it too much.

But while I feel like PLA is mostly fine and maybe gets a bit brittle after a while, PETG does start to show just a bit more stringing than the same stuff new, and styrene-based filaments like ABS or ASA, I think do smell a bit more than if they were completely dry.

Three things that you might start to notice with wet filaments

- Changes in mechanical properties:

With PLA, I don’t know if there’s something chemical happening, but for example, parts printed from wet PETG are supposed to be less strong. What’s happening here is that as the water absorbed into the filament rapidly boils off as it gets heated in the hotend, that motion of the steam actually tears apart the polymer chains that give plastic its durability. So even though your parts might look fine, because the polymer itself is supposedly altered, they might perform very differently than what you’d expect. That’s actually a similar reason why resin prints are often brittle – the cured parts have shorter polymer chains because optimizing a resin for longer chains would make it harder to print with.

- Stringing:

Again, as the moisture boils off, it creates little puffs of steam, and those push the molten filament around, and in a hotend, there’s only one way to – out of the nozzle. You overall just get less precise control over the filament flow.

- Increased amounts of smell:

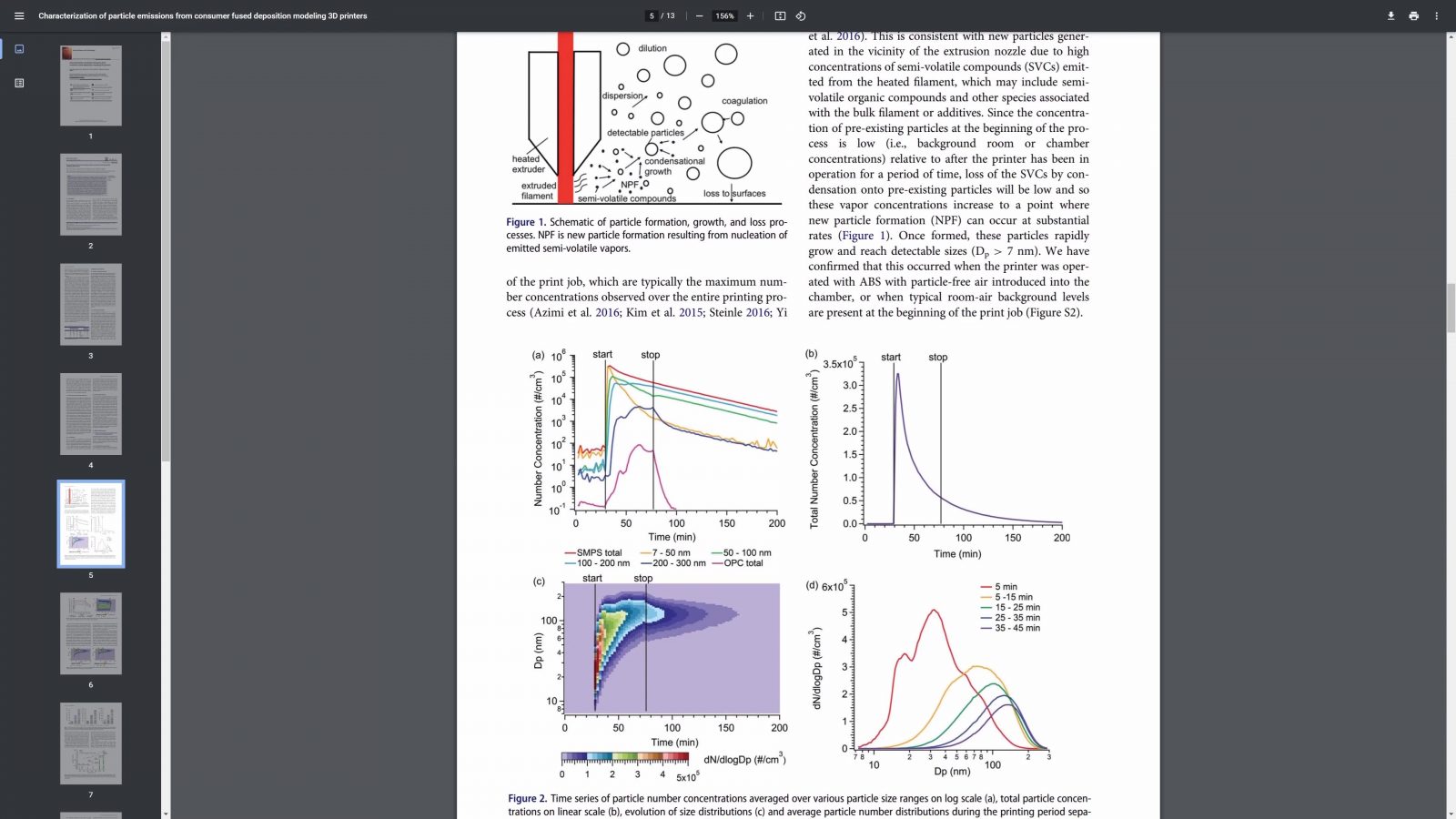

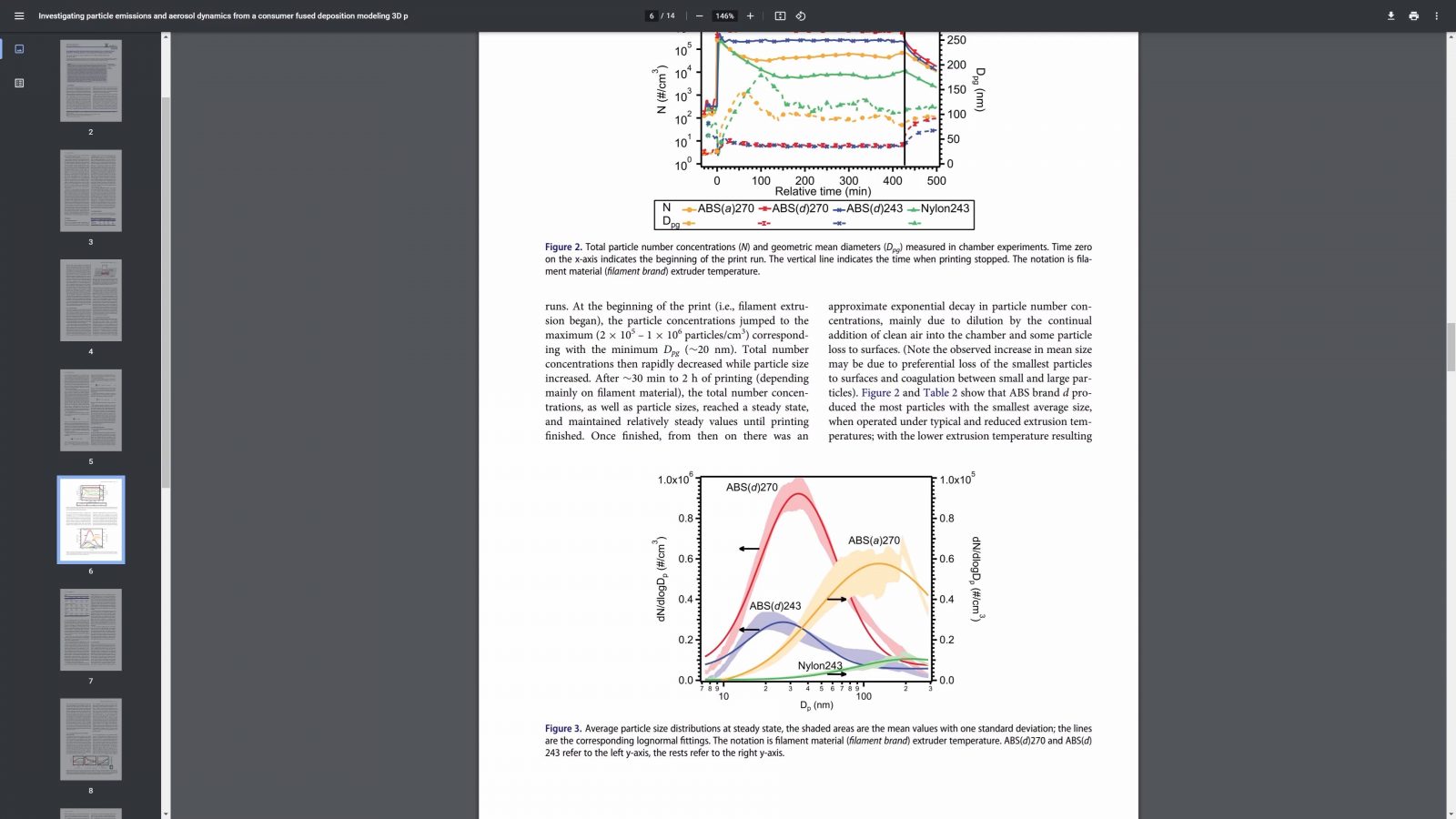

This one is hard to measure, but thankfully a couple of studies have already looked into this. What we can notice is an odor, but what can be measured is particulate emissions from the print. As the filaments moisture content or the hotend temperature goes up, the emissions of fine and ultra-fine particles drastically increase, easily up to a point where it’s not quite healthy anymore to be in the same room with a printer.

So yes, this was something that I did notice, I think, but I didn’t quantify for these tests. I do have two particle sensors, so this might be something to look into for next time.

What exactly did I test?

Well, the first question was, how can I quantify how much moisture is being absorbed and how much of a difference it makes? So the first one should be fairly easy – grab a scale that weighs down to 10 milligrams and just weigh the filament samples fresh and after having some time to soak up some moisture. So I did that. For these tests, I’m using all-Prusa parts, that is a Prusa MK3 and PrusaSlicer which also has built-in factory-tuned profiles for the Prusament I’ll be using. I could have saved a whole lot of print time by using the Voron, but then I’d never have known whether what we’re seeing is my profiles or the material itself.

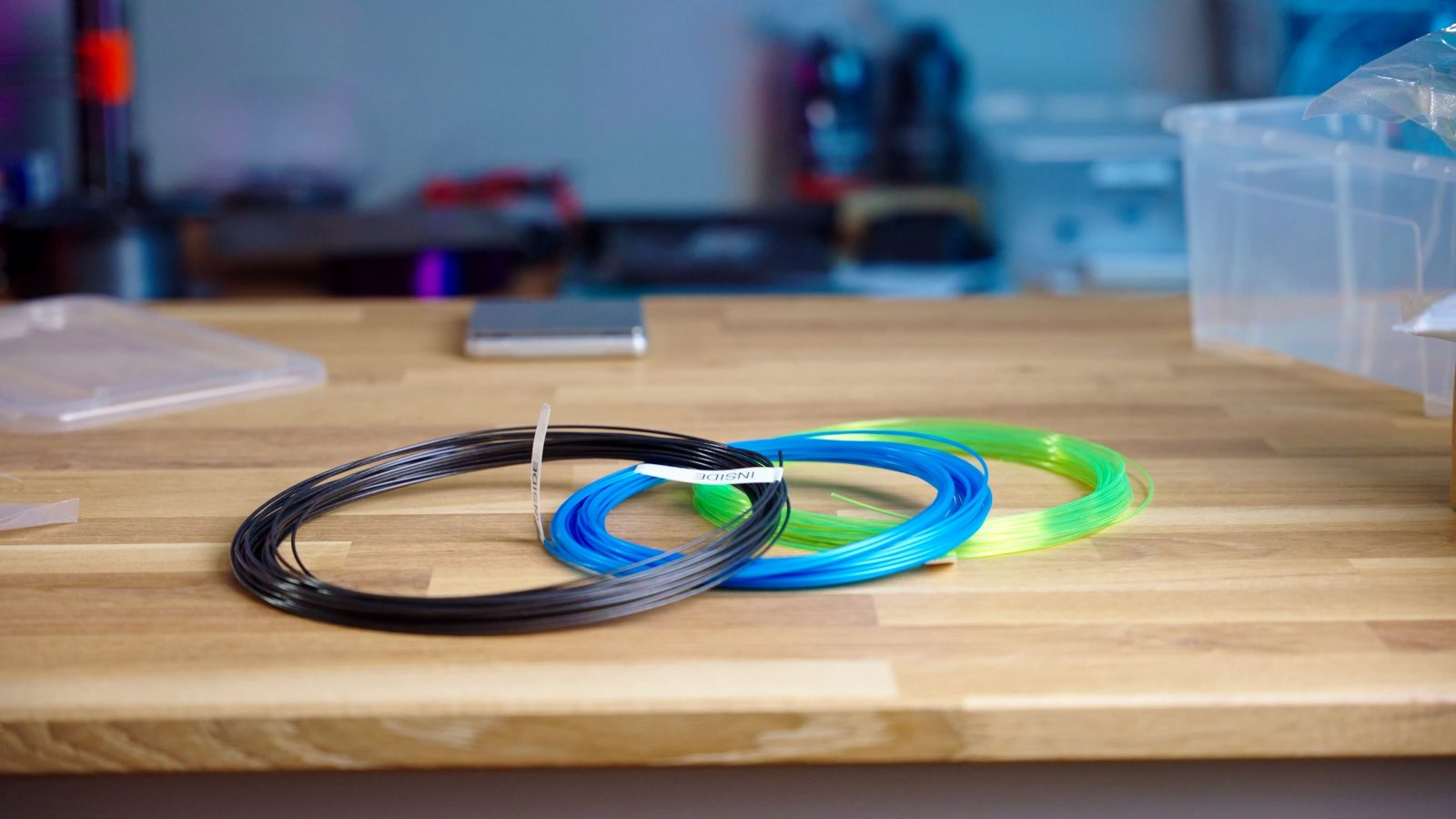

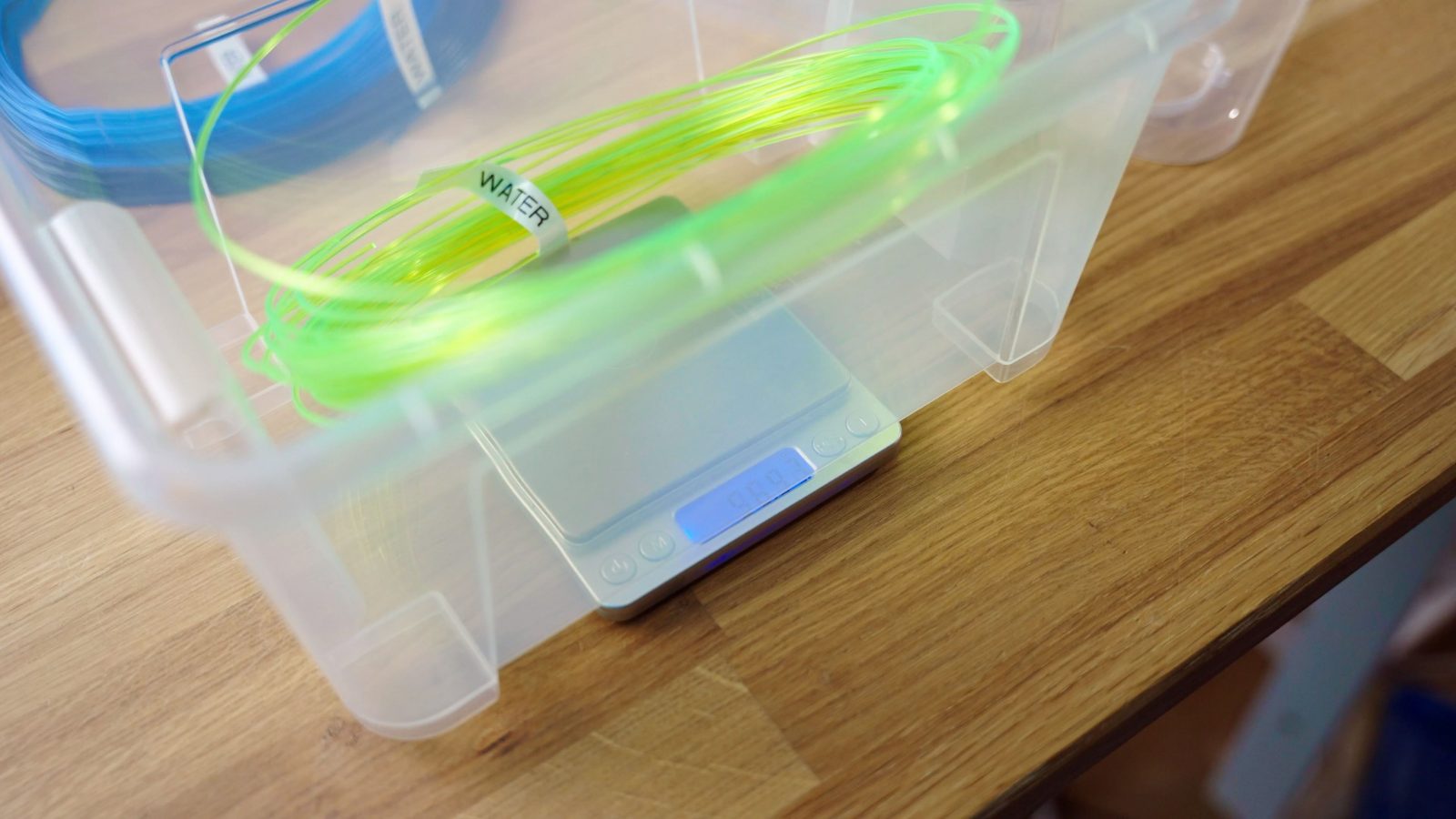

So I roughly measured out roughly 15m long samples of Prusament PLA, PETG, and ASA, enough to print my samples and a bit extra, and they went in a couple of different spots.

inside

outside

water

The first set stayed here in the studio, with no enclosure or anything, this room is relatively cool, it’s around 18 to 20°C, but there is a dehumidifier running that’s set to 50% relative humidity. So fairly good conditions to store filament in, I think. Of course, it’s still better to store it in the original bag with some desiccant, which I also did with the remainder of the spools and then used those to print some samples with what is 100% fresh filament.

But the next set of filament samples went outside, it was fairly cold and foggy these days, a bit below freezing a couple of nights, so this should be a good portion of humidity that the filament is getting, but just to make sure we’re also capturing the extreme end of the scale.

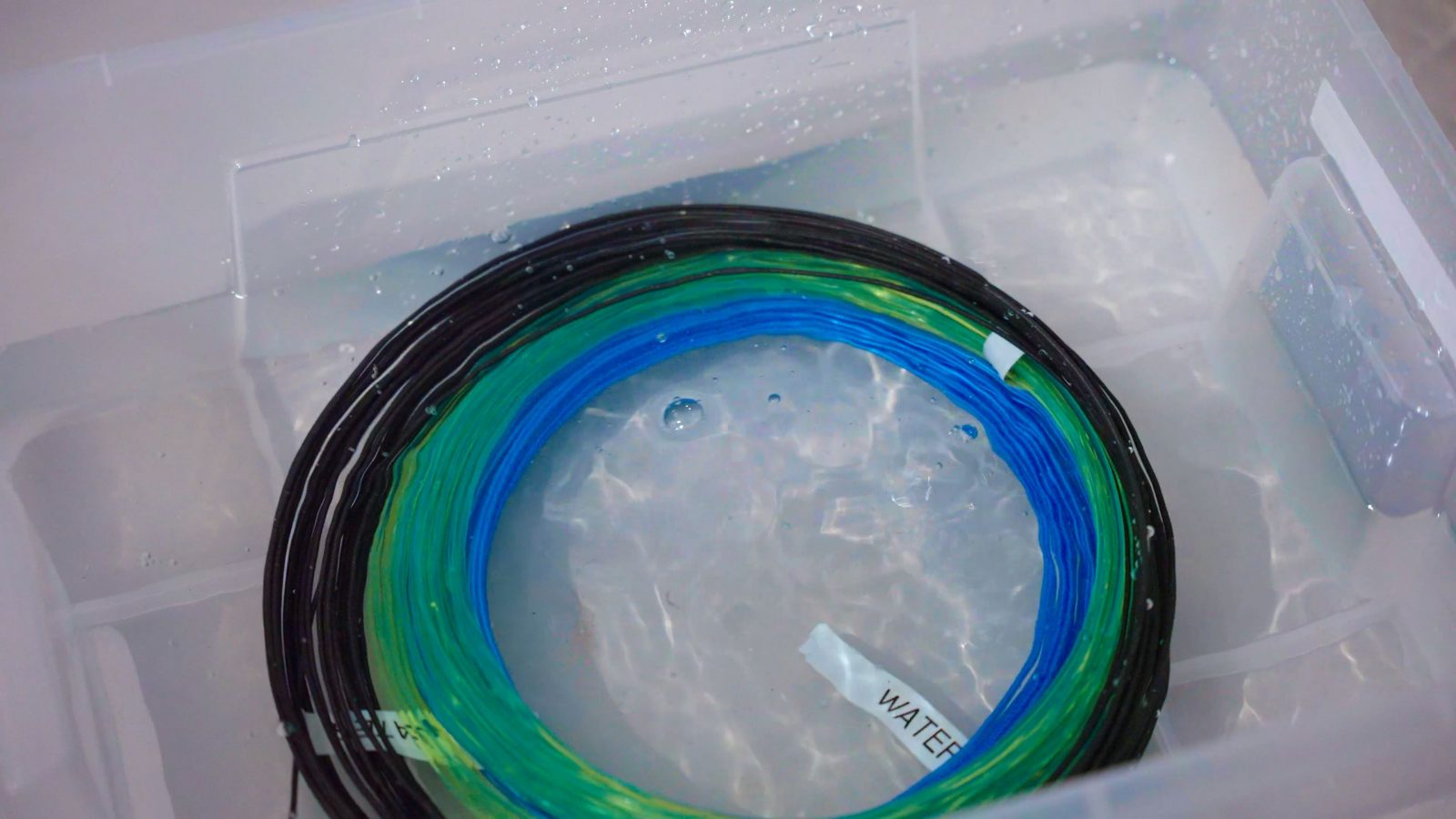

I also dumped some samples into a bucket of tap water. Like, actually, submerged them and let them sit at room temperature. Short of heating up the water or pressurizing it, I don’t think there’s a way that these samples would be absorbing any more humidity than this.

I labeled all the filaments, let them sit for 7 full days, and then came back and weighed them before starting to print with them.

And this is where things started going wrong. Because I absolutely couldn’t measure any weight gain at all, and some of the samples looked to have even lost weight according to the scale. So this scale supposedly has a 10mg resolution at up to 500g of weight. It doesn’t. Not even close.

Turns out it does at best 50mg, and usually more around 100. With a sample weight of around 50g, that’s 1 or 2% of weight difference instead of the advertised 0.2%, and it’s just not enough to discern “wet” from “dry” filament. Nylon can absorb as much as 10% water by weight, but typical absorption rates of e.g. ASA are more around 1%, so there’s no chance I could have measured anything here. Oh well.

Printing and Print Results

What followed was a full week of printing and reprinting parts, some of the test plates had a part come loose and I was really starting to worry that the 15m filament samples weren’t going to be enough, but in the end, it barely worked out. With these plates, I printed each of the parts in sequence, so that they actually get printed one by one. Octolapse really doesn’t seem to get along with that print mode, though.

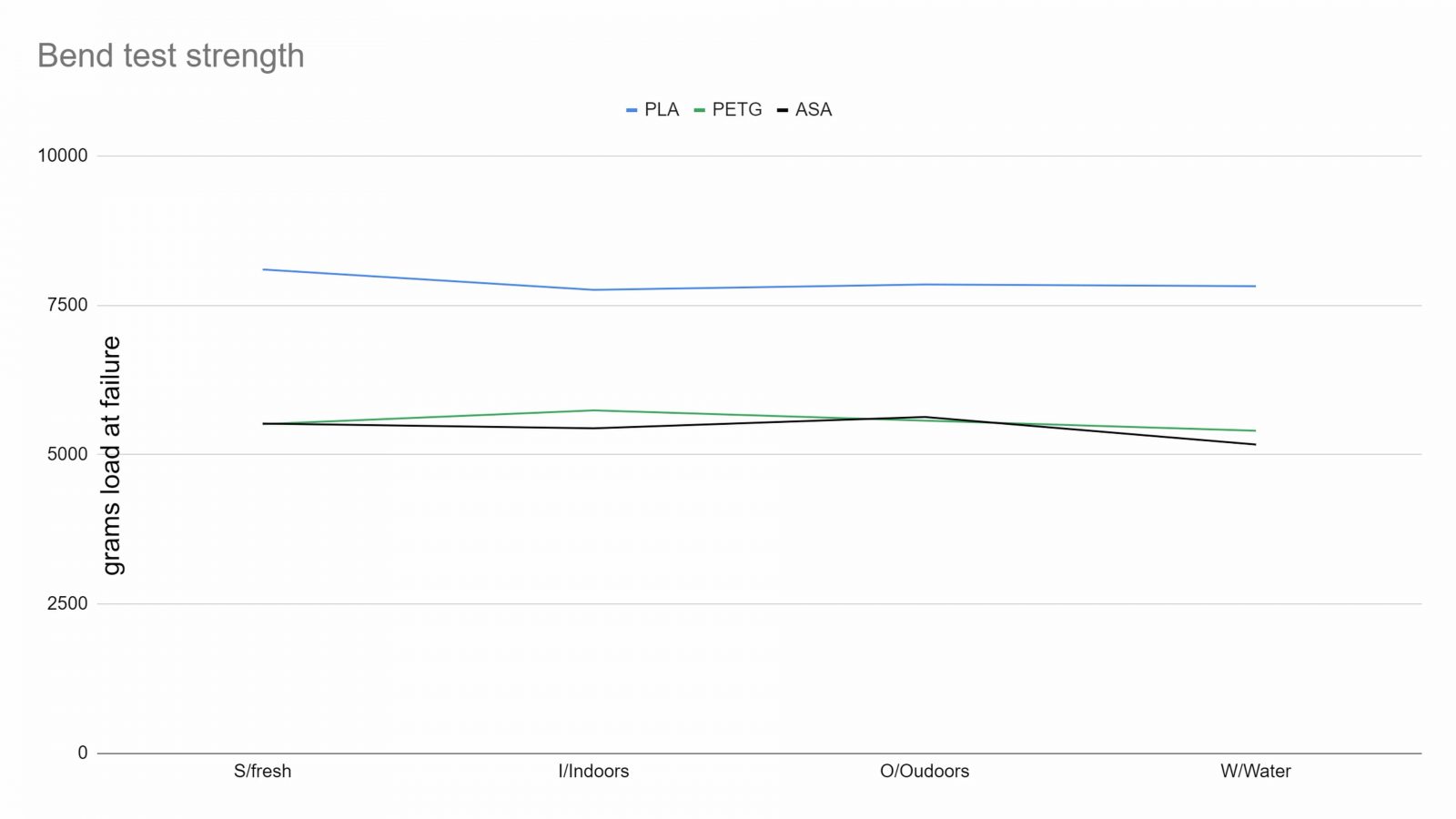

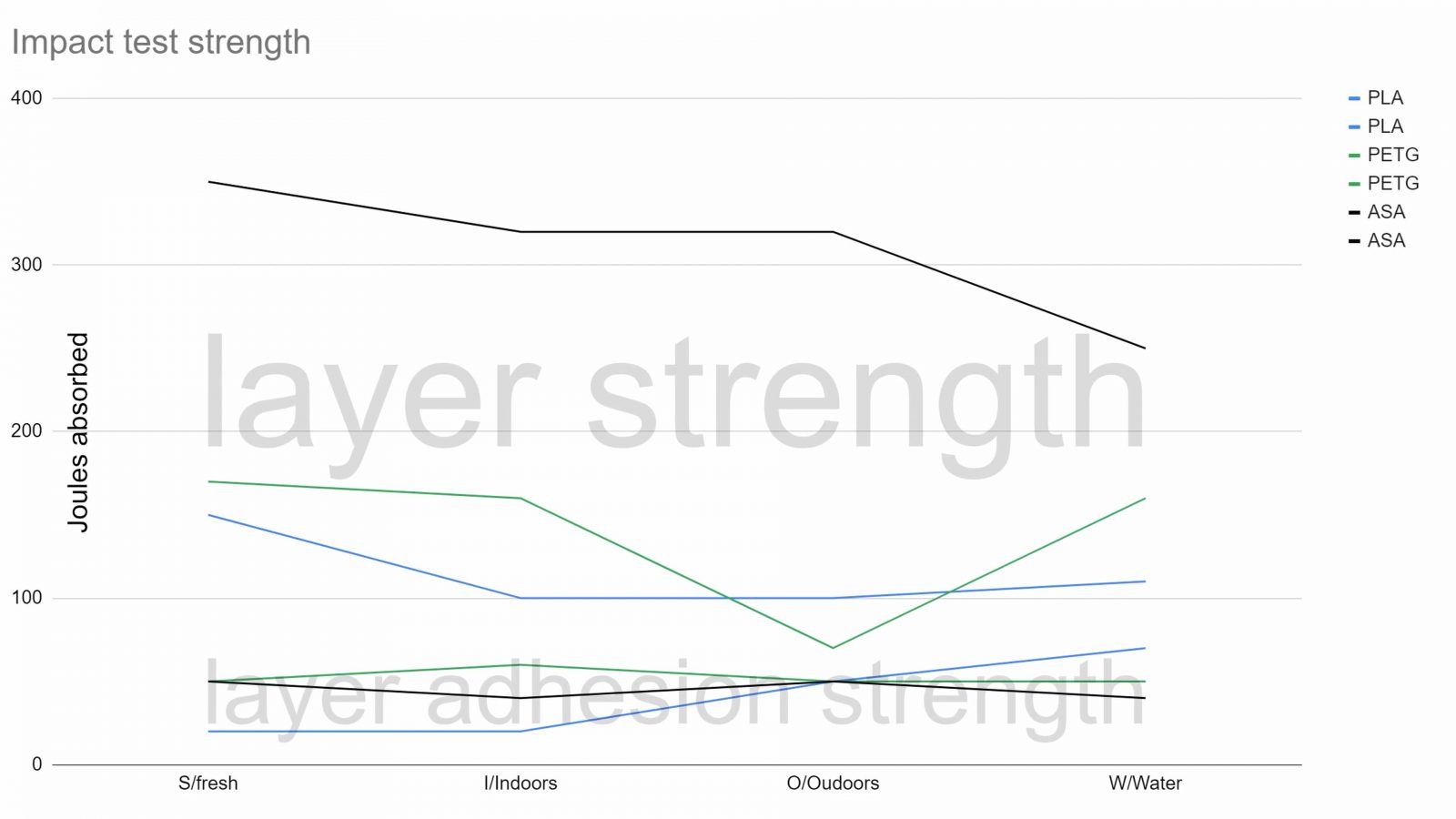

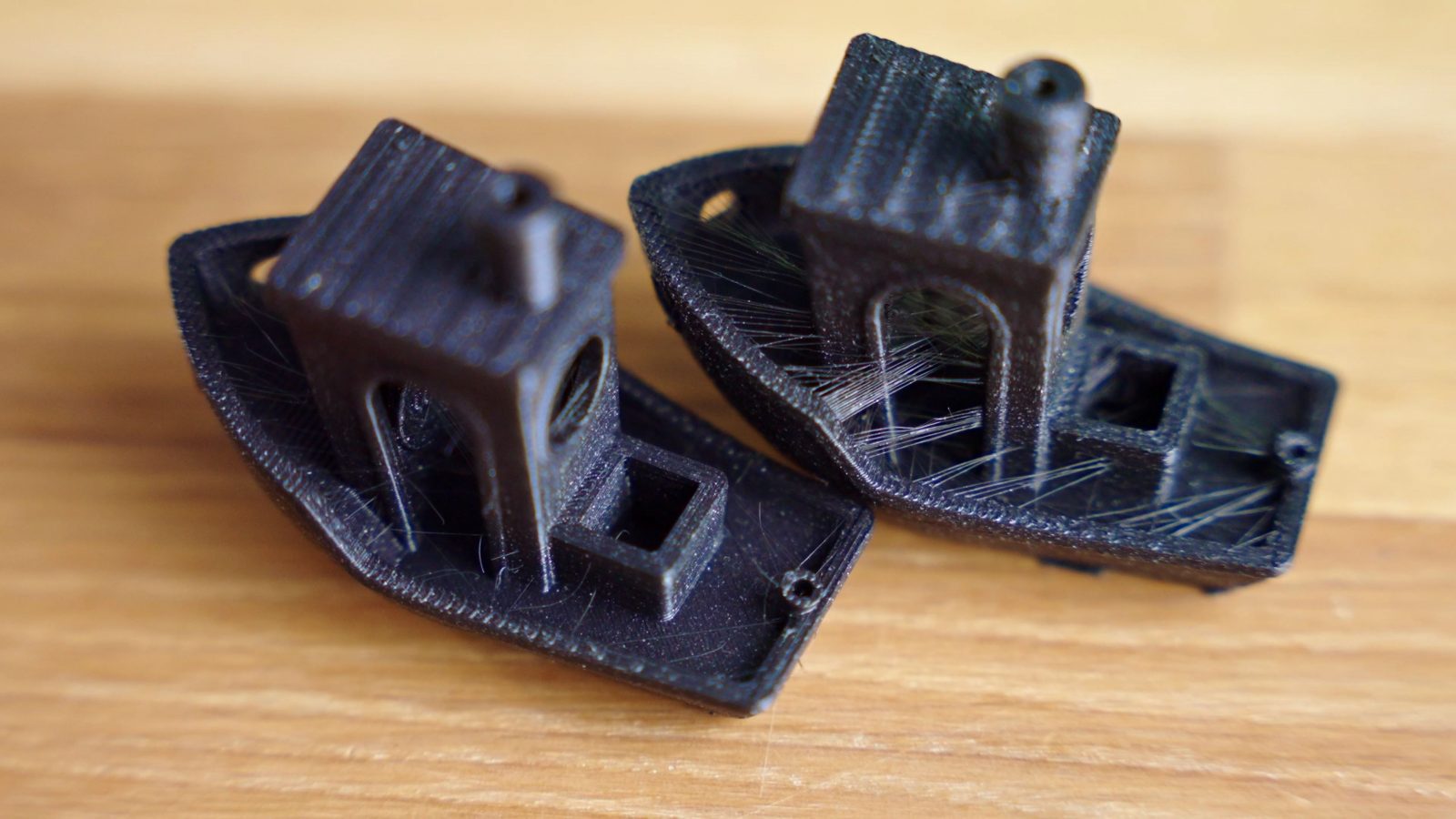

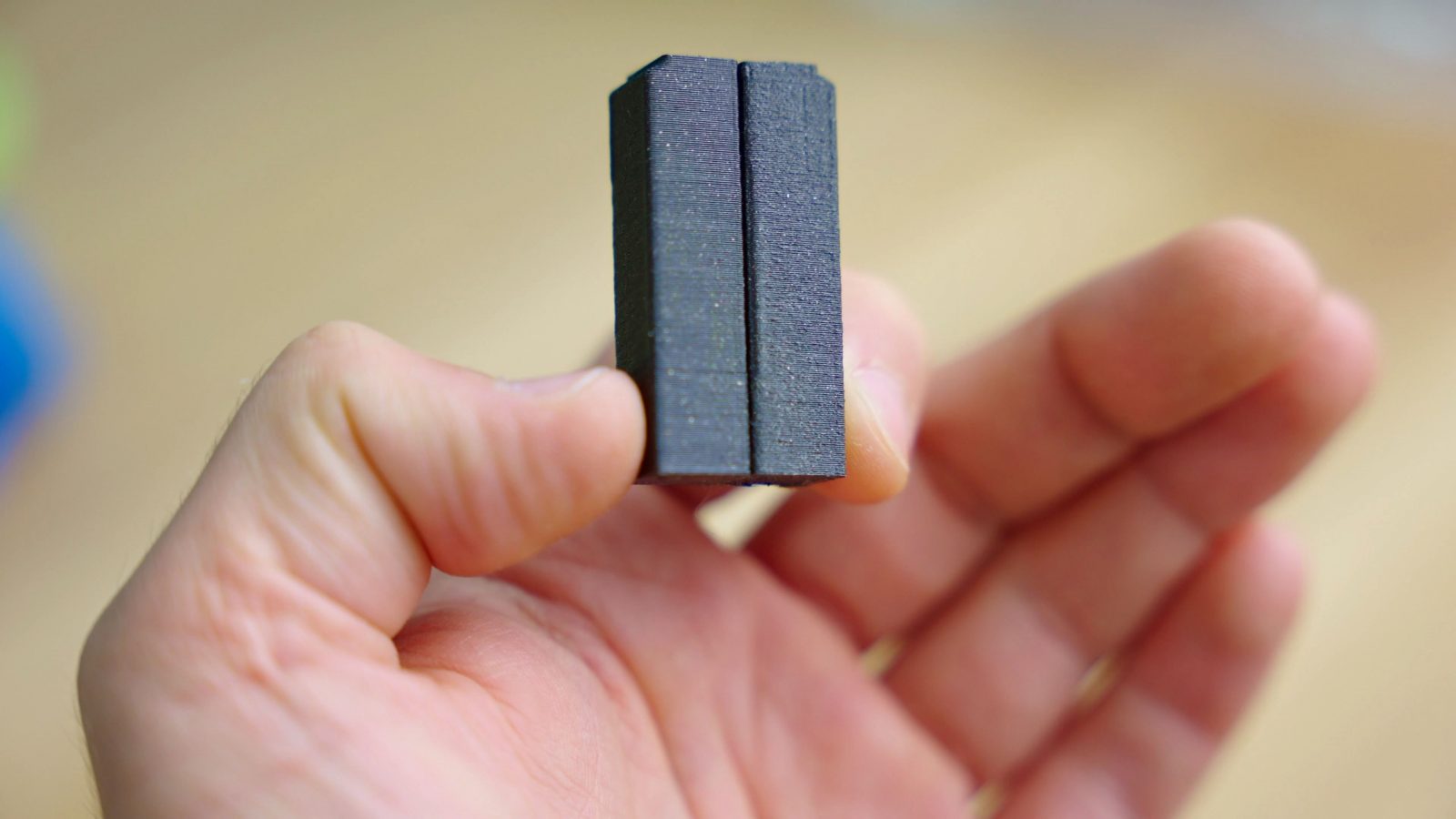

So we’ve got, of course, a 3D Benchy for each of the materials and “wetness” state, my filaween bend test, printed laying down flat, and an IZOD impact test printed laying down and standing up to see whether layer adhesion or layer strength would suffer more. These were all done with the Prusa Slicer 0.2mm speed profile, so they do use infill and are not solid parts. The important bit to me is that they’re similar to how you’d actually be printing stuff.

Visual quality

There are two things that I’m noticing. First, stringing, as expected, does increase the more moisture we put into the filaments, but differently for each material.

PLA

PETG

PLA doesn’t seem that affected, but you can see just a little bit more stringing for each step between fresh, stored indoors, stored outdoors, and underwater filament. PETG has more noticeable degradation, but on the outdoor and underwater prints, the chimney is now all swollen up and over extruded, too. This is the area of the Benchy where the printer has to slow down to not overheat the part as it’s being printed, and I guess with the PETG spending more time in the hotend, that allows it to get cooked more thoroughly and the escaping steam can have a larger effect in pushing out filament.

ASA indoor and underwater

ASA is somewhere in between these two, with some over extrusion on the chimney, but also a larger increase in stringing between the outdoor and underwater filament. Also, the underwater filament really smelled a lot like ten years ago when we were mostly still printing ABS.

Overall, every single filament was already affected by being stored indoors. For PLA, it was not that bad, but it’s still a noticeable difference which, honestly, I didn’t think there would be. But it’s there.

The other thing that was noticeable was actual bubbling in the prints, especially in the areas like, again, the Benchy’s chimney where the printer slows down. The main thing I’m noticing is either a very rough-looking surface finish on ASA, almost like Colorfabb’s foaming LW-PLA, or the part being more of a milky translucent instead of true crystal clear with PETG.

rough surface on ASA

milky PETG

Which, honestly, could actually be desirable if you want to create a diffuser for softening up a light source, for example. Though this extra foaming is really only noticeable on the very wettest of filament samples. So if you see this on your own prints, well, something has gone horribly wrong somewhere.

So, okay, optically, there is a very noticeable dip in quality the wetter the filament is.

What about strength?

Well, remember how I said “things *started* going wrong” – well, this is where that continues. Because I couldn’t actually measure a difference in strength, either. So you know the Filaween testing sets, I’ve always tried to not make those look like they are actually scientifically precise tests because frankly, I just can’t provide that with reasonable effort. So there is some variance in there, there is some human error that can influence the results, so if, for example, two results are within, maybe 10% of each other, first of all, that’s not enough for me to say “this is clearly better than the other”, but also, in practice, you’re most likely not going to notice a difference at all. Sure, printing more samples would improve this, but this was already plenty of printing as-is.

This is the bend test, where I take the sample and bend it until it snaps or develops a sharp kink, and there’s, well, not much. Which is surprising, honestly. My prediction would have been that, at least for PETG, there would be some measurable decrease in bend strength, but with these tests always have been quite consistent and repeatable, seeing practically no dip in strength, even for the wettest of samples, that’s just something that I’m going to have to take as fact until proven otherwise. Now, keep in mind that the lack of extrusion control that we saw before can still mean you’re getting weaker parts overall, but it looks like it’s not going to be because the material itself got significantly weaker.

For the impact tests, there was something that you could call a trend towards lower impact strength for all materials, but given how much the readings fluctuate here, I just don’t think this is significant enough. The layer adhesion tests are basically all noise already, and even the layer strength ones don’t seem particularly trustworthy. So there might be something there, but this set of data doesn’t show it.

My Conclusion

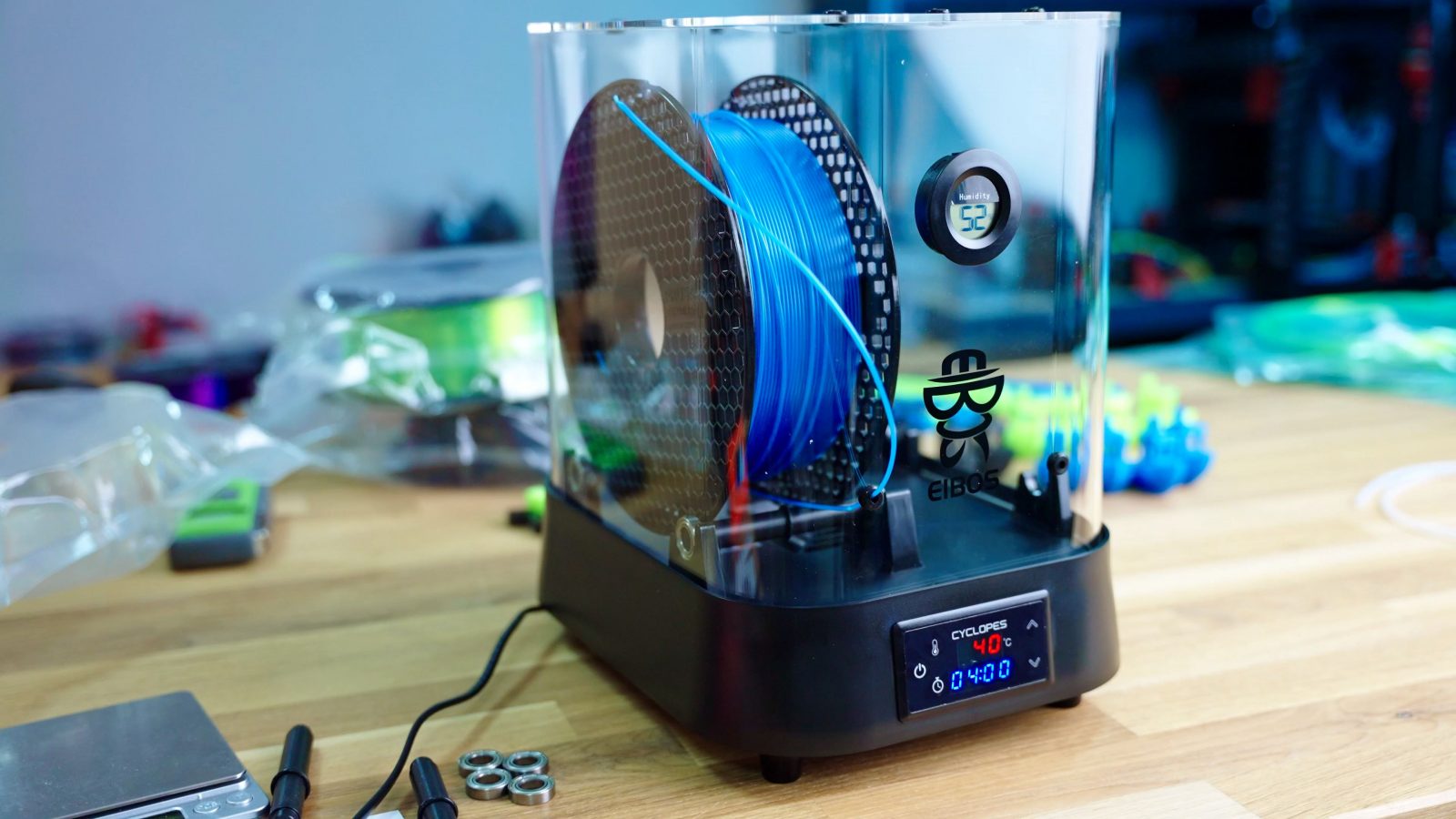

So what do we learn here? Couple of takeaways here that I’m going to keep in mind for the future. First of all, seven days of exposure to an imperfect environment is already enough to degrade print quality, even for PLA. PLA is most likely fine to be stored in a low-humidity room for day-to-day printing, but there’s still a quality gain to be had for storing it perfectly, like in a drybox. PETG and ASA definitely gain a lot from being stored well, so if you want perfect prints and have had your filament sitting out in the open, you’re best advised to dry it first. This was actually going to be the main part of this video, how to dry filament, whether it’s in an oven or in a drybox, like the one that Eibos sent me, but for lack of a suitable scale to measure stuff, I had to cut that out of the video.

So while print quality and dimensional accuracy definitely suffer with all materials, it doesn’t look like material strength decreases too much. So if you just need strong, and not-too-precise or pretty parts, I guess leaving filament out in the open could actually be totally fine.

But, as always, there’s definitely more testing to be done.

Thanks to everyone who’s supporting the channel by watching, liking, subscribing, or sharing, or even directly through Patreon or YouTube memberships. Thank you.

Products shown:

Eibos filament dryer: on Amazon

Eibos filament dryer: on Aliexpress

💙 Enjoying the videos? Support my work on Patreon!

Product links are affiliate links – I may earn a commission on qualifying purchases (at no extra cost to you)

Check out my second channel “More Layers” on YouTube for livestreams

Check out the Meltzone Podcast (with CNC Kitchen)!