Today we’re going to have a look at the Flashforge Voxelab Aquila. Can you tell which one of these is the Aquila? Yeah, I can’t either. And I think that’s a problem.

But first, let’s start out with the Aquila itself. It’s a 220x220x250mm build size, 32-bit board, silent drivers, 0.4mm nozzle, color LCD screen, silicon carbide coated glass bed, no auto-leveling, no filament sensor, the standard Creality-style hotend, good print quality, but plenty of design flaws and a price of between 150 and $200, depending on when and where you buy it. It’s pretty much the same recipe we’ve seen repeated over and over again over the last years with minimal variations, and just like all the other Ender-3 clones, this one is… fine if you turn a blind eye to a couple of things.

Though, honestly, I was expecting a little bit more after I saw the hype from you guys for this very machine back when I was working with the Elegoo Neptune 2.

Let’s start with the good stuff:

Print Quality

Like I mentioned, print quality is actually really good. On par with what the other machines in its class can do, and if everything works well, easily competitive with the big boys as well. Print quality out of the box is something that you should really be able to take for granted these days. Speaking of out-of-the-box, the unboxing and assembly are fine, too – the manual is well done, the assembly itself isn’t overly complicated and in general, you shouldn’t have any problems getting this printer running. They even tell you to adjust the v-wheels on the bed and carriage, but as all manufacturers do, forget to instruct you to actually lock them, so, as, on other printers, these wheels will come loose over time. Easy fix, though. The manual does basically end once you’ve got filament loaded and are printing the first included parts as the included troubleshooting Q&A is questionably useful, with tips like adjusting the transmission ratio if the accuracy isn’t good. Like, I don’t even know what they’re trying to say here.

Slicer

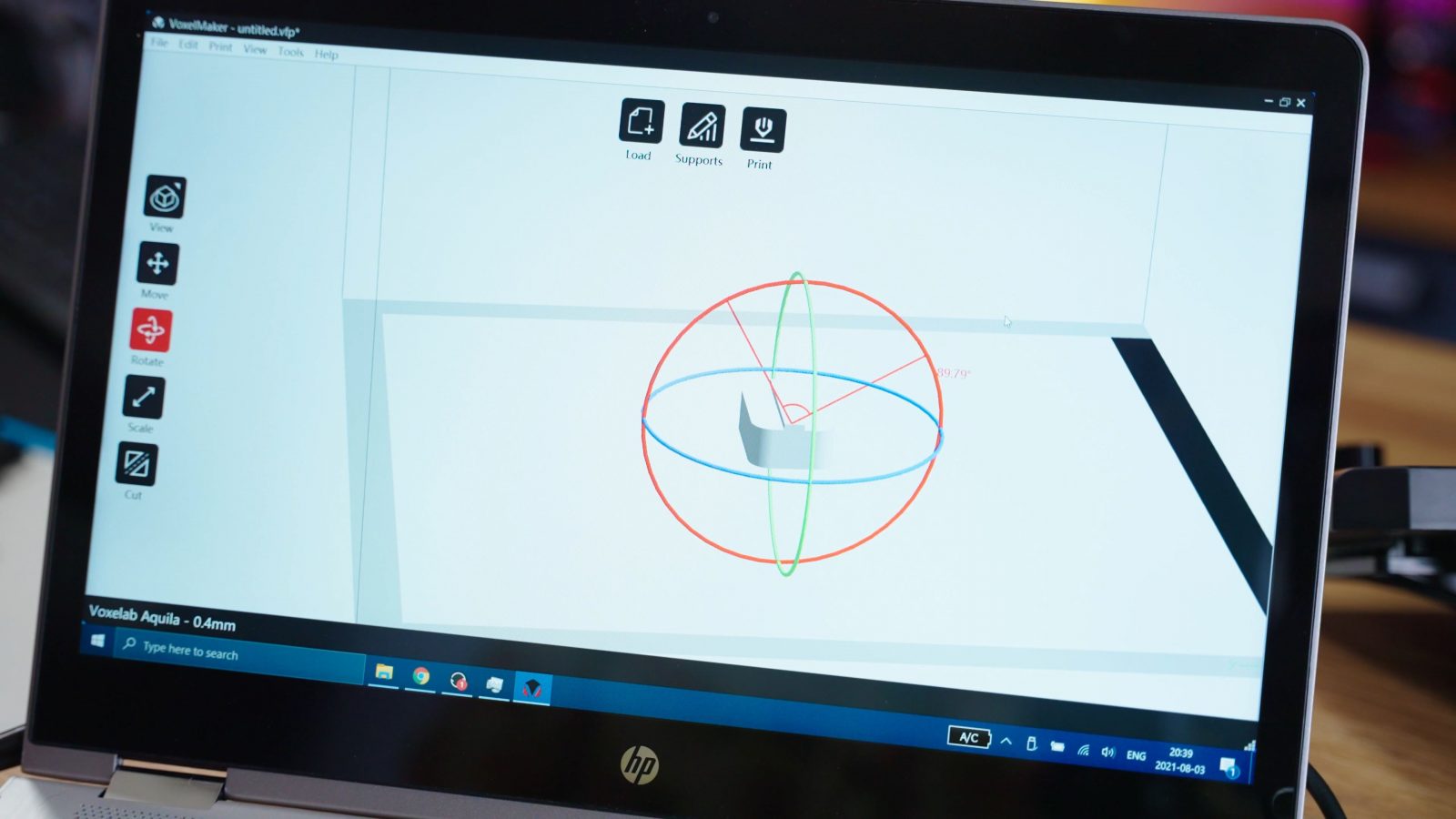

They are including their own slicer VoxelPrint, a renamed version of Flashforge’s, you guessed it, FlashPrint, which is pretty basic and has a few quirks still, like by default generating supports that work for resin prints, but not for filament printers, and estimating print times at least 30 to 50% too short, but it’s totally usable and produces good results, but as always I wish they would just use and possibly contribute to the excellent open-source slicers Cura and PrusaSlicer. Both of those are open for any manufacturer to submit their printer profiles and be included in the official releases, or like Elegoo and Creality are doing, for manufacturers to create branded versions. I just doubt that Flashforge Voxelab has the ambitions to develop VoxelPrint to a level where it could rival either of the open-source solutions, so I think using those would be the better choice.

LCD Screen

On the printer, really the only thing that stands out is the comfortably-sized LCD screen. It’s not a touchscreen, and instead uses a physical click wheel, which I much prefer, especially since the interface is responsive and straightforward to use. You can still tell it’s a bit of a tossed-together mashup of nicely antialiased jpegs and hard, generated text, but it does the job. What I do miss are graphical print previews on the screen – it has the space to show them, but even though they’ve got their own slicer which should easily be able to include those with print files, for some reason, that’s a feature that’s missing.

But what’s actually missing more than anything else is any sort of innovation or improvement over the dozens of other Ender-3 clones. Like, at this point in the review, I’ve already talked about everything that’s unique to Flashforge Voxelab Aquila that I can say. It’s an Ender-3 clone with a big screen. That does not feel like enough of a reason for this machine to exists alongside all the other versions. Angus just did a fantastic video on a range of topics about the, let’s call it “weird” stuff 3D printer manufacturers are doing and one of his points was that really, manufacturers are throwing as many machines onto the market as they can, just to take up space of storefronts, get more coverage by reviewers and overall drown out everyone else who tries to sell a 3D printer, too. This is one of those machines that is done with the absolute minimum of engineering effort required to produce a “new” product.

Like, look at all the flaws that they perpetuate with this very machine.

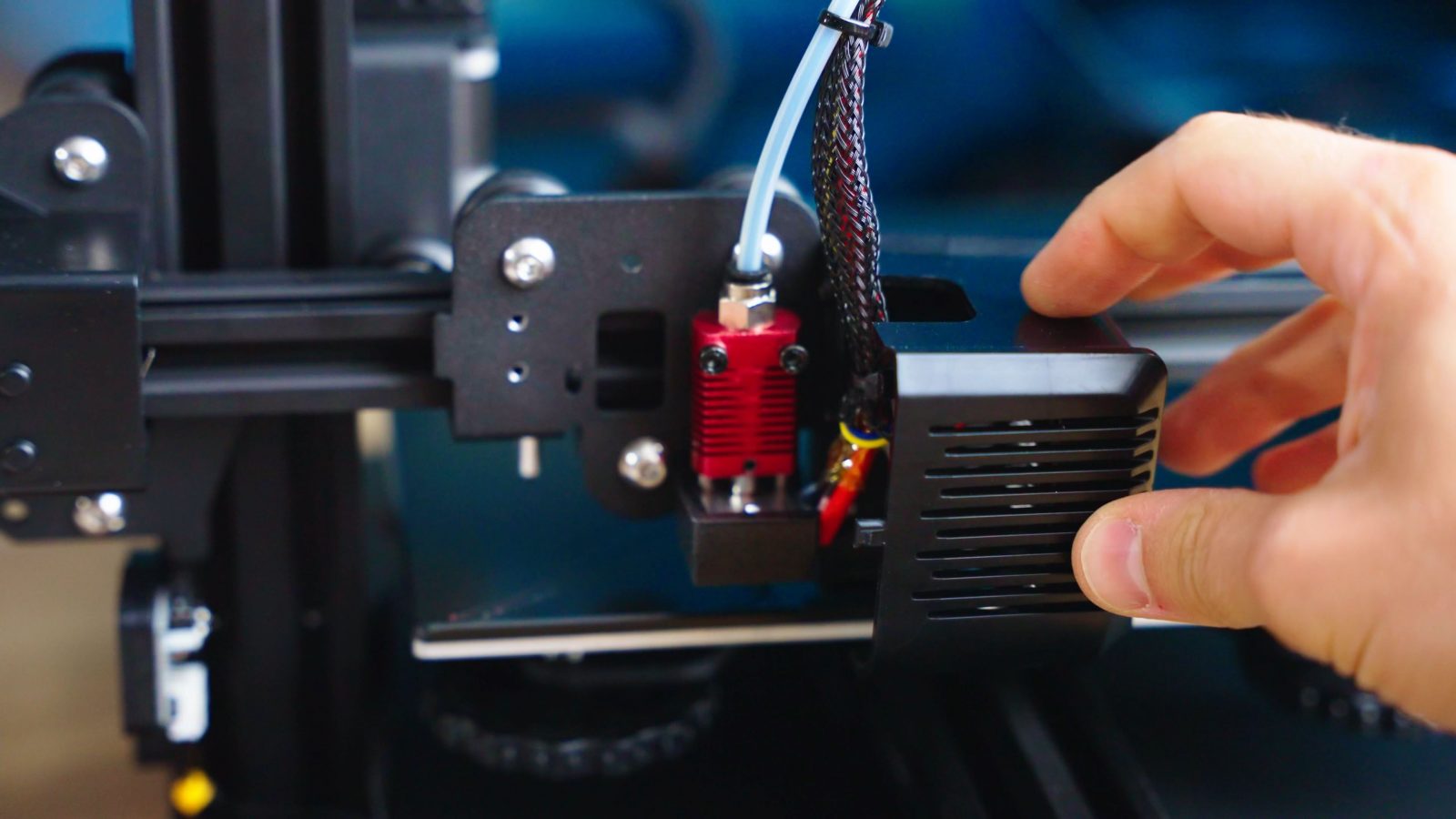

Hotend and Extruder

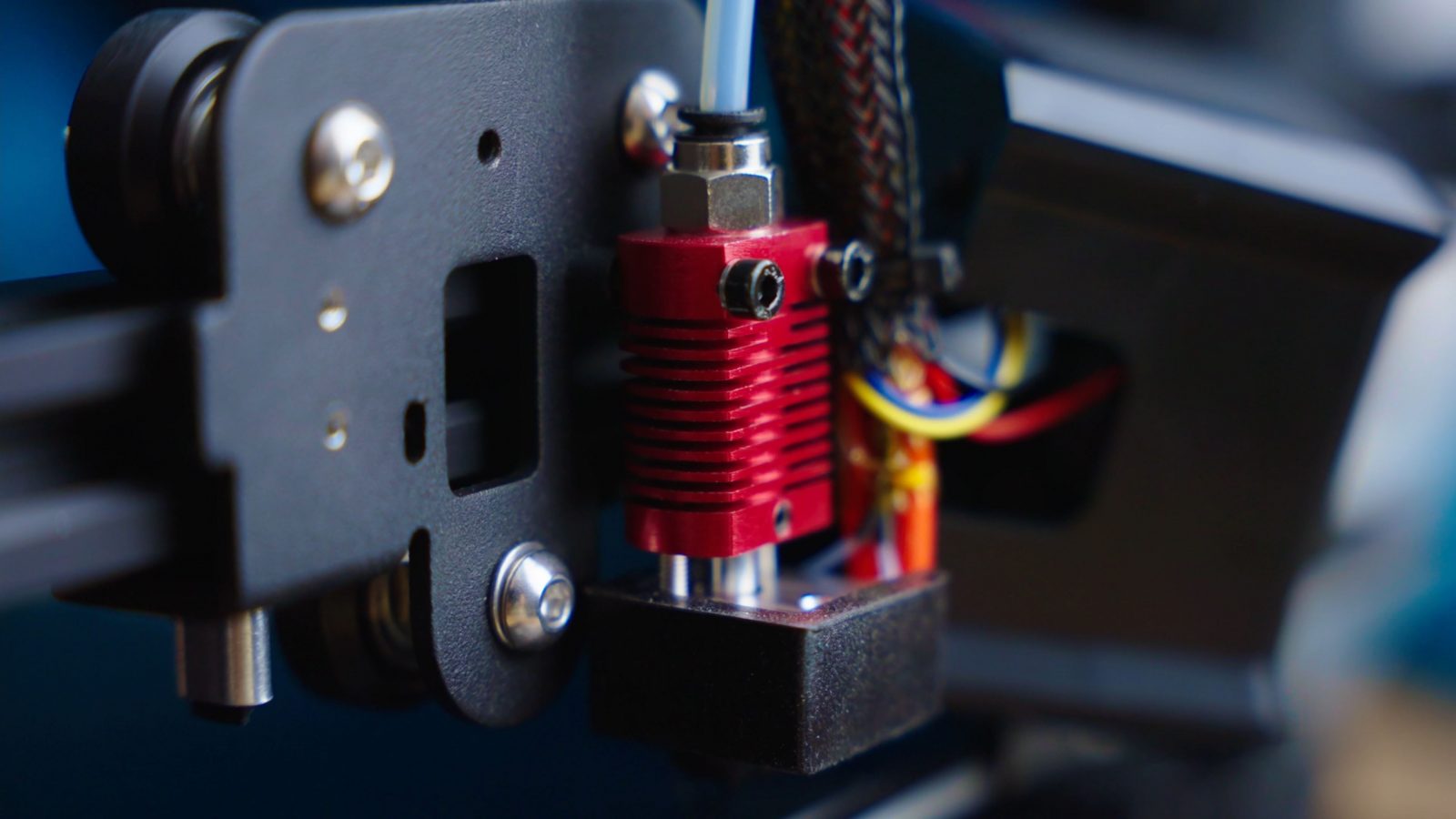

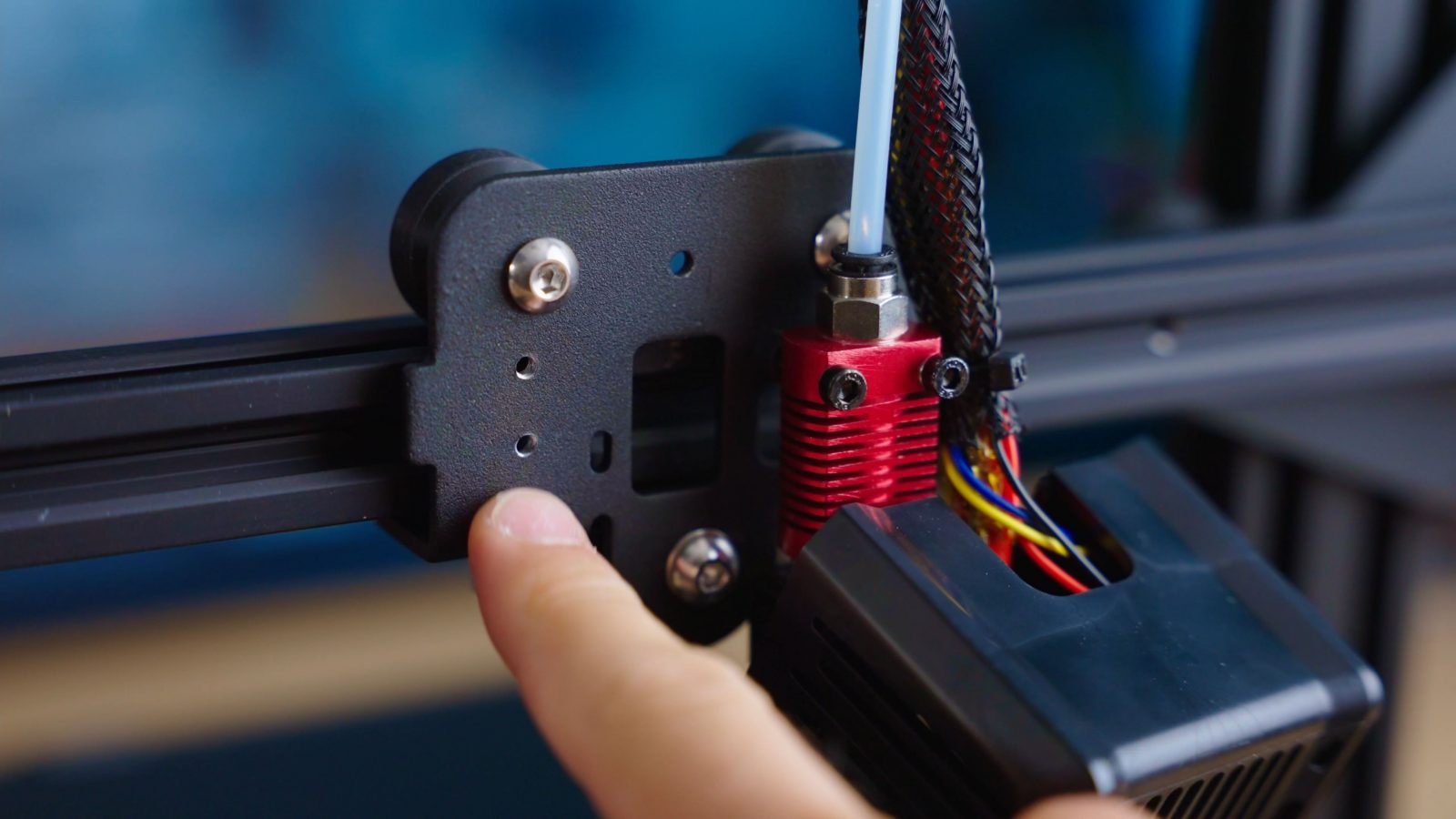

Let’s start with the core 3D printer functionality – the hotend and extruder.

The hotend is a standard Creality-style Teflon-lined one, where the Bowden tube runs all the way through the hotend until it touches the nozzle. That’s a design that is notorious for failing over time, as the Teflon degrades, deforms, and constrains the filament path, and notorious for the Bowden coupling slipping, so eventually the hotend will produce jams and hiccups that are pretty hard to identify unless you know exactly where you’re looking.

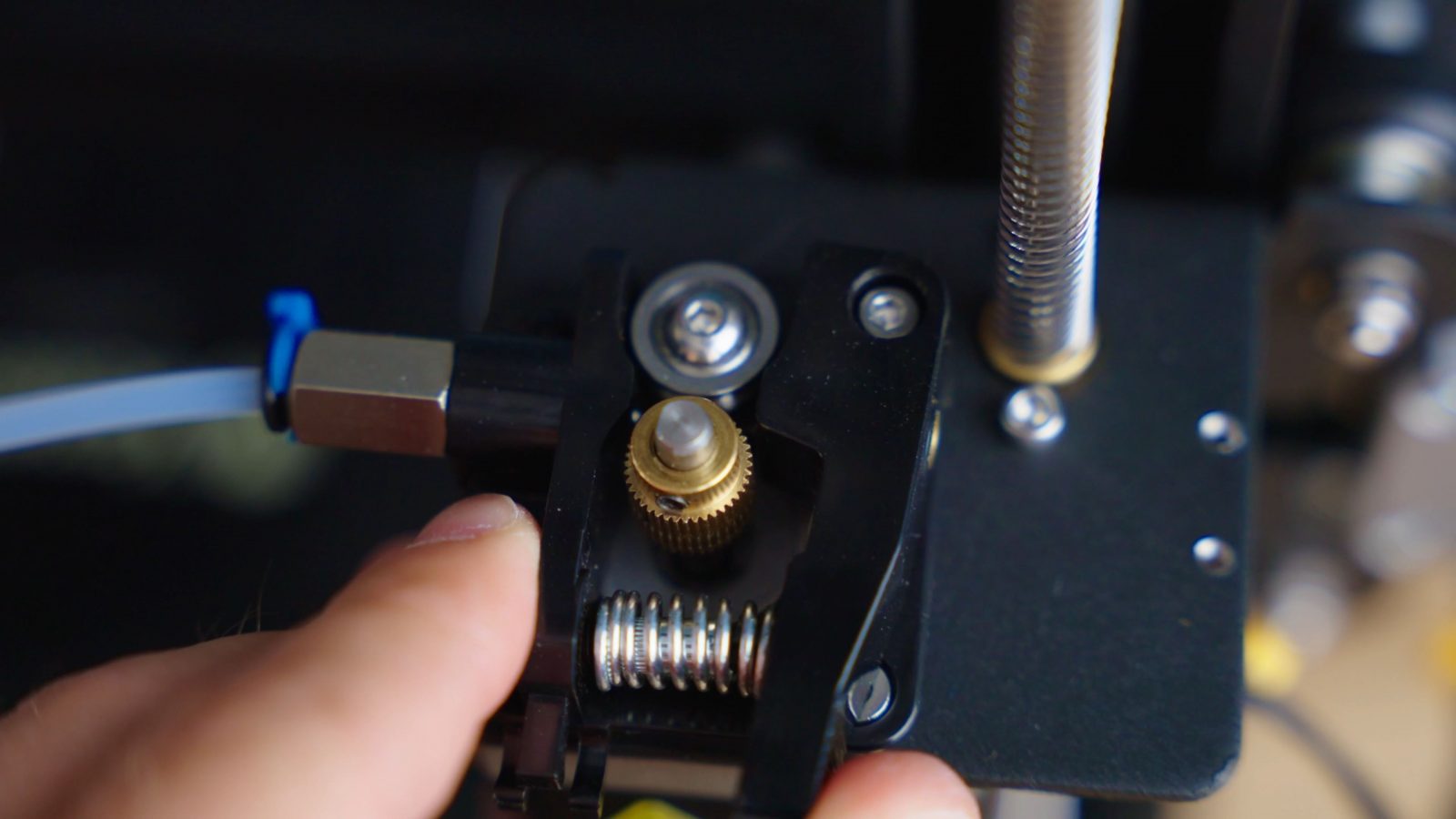

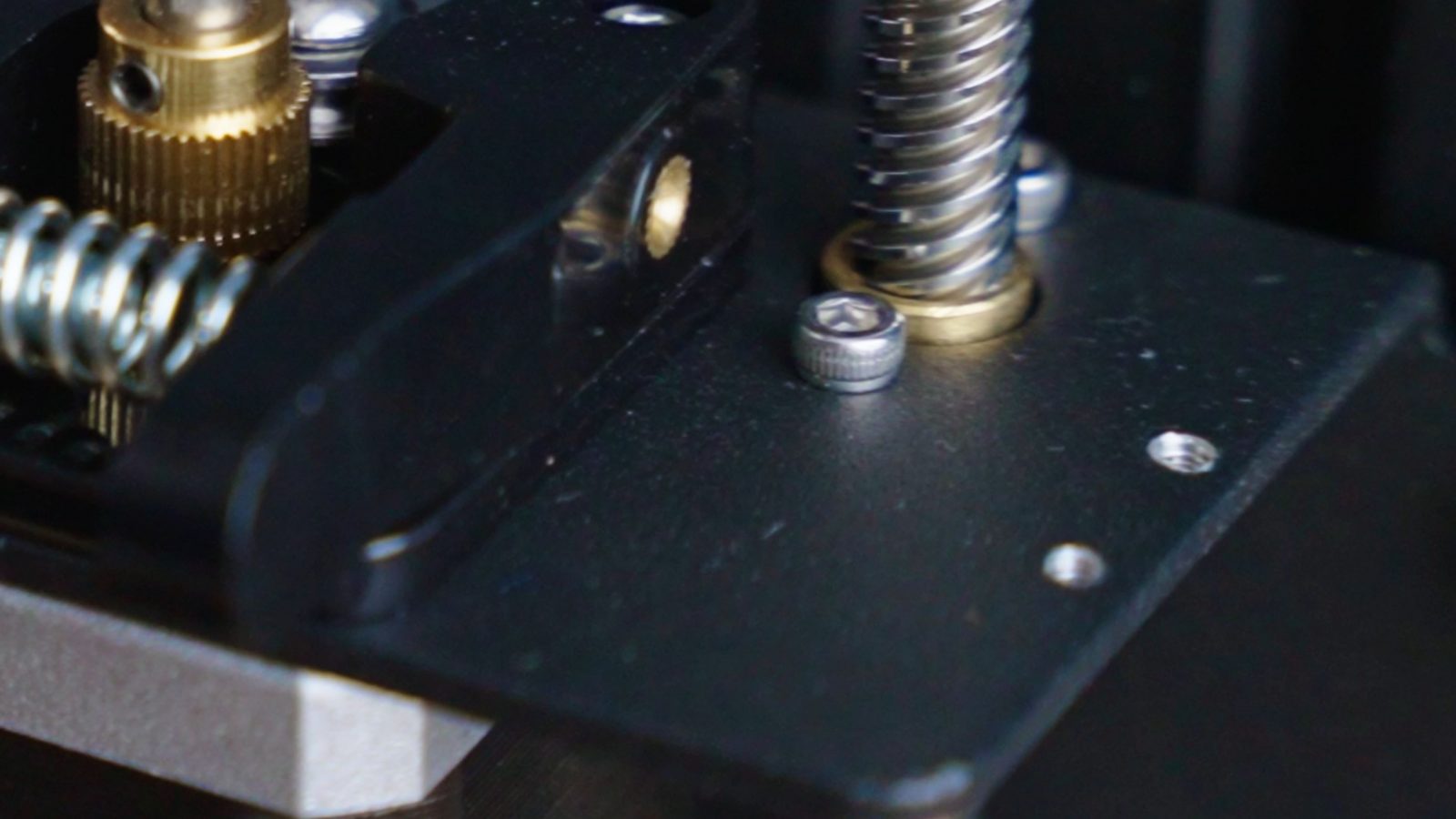

The extruder. Same 49ct plastic construction with a single brass gear driving the filament. It works fine for now, but as the brass wears down, it’s only going to get duller. And there are also plenty of reports of these extruder bodies starting to crack.

Cable Mangement

Then, the everlasting issues with cable management. On the Aquila, the major cable bundle rides straight over the IEC power connector and essentially blocks the on-off switch, but also, the wiring coming out of the bed, it has so much reinforcement that I guess they thought was useful as a strain relief, that they simply ended up moving the spot where the bed wiring kinks, instead of preventing it – and eventually that’s going to fail, just further away from the bed.

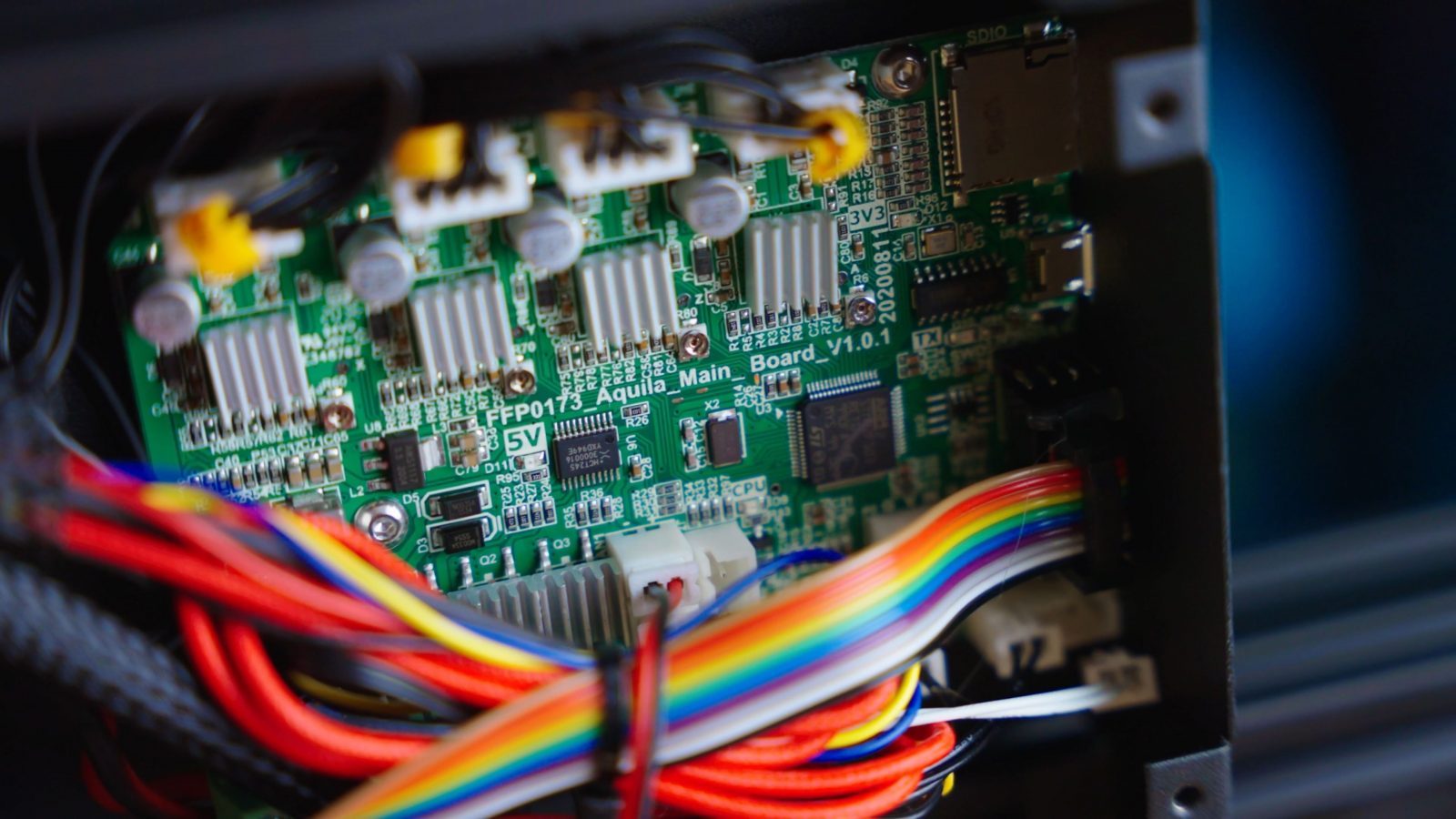

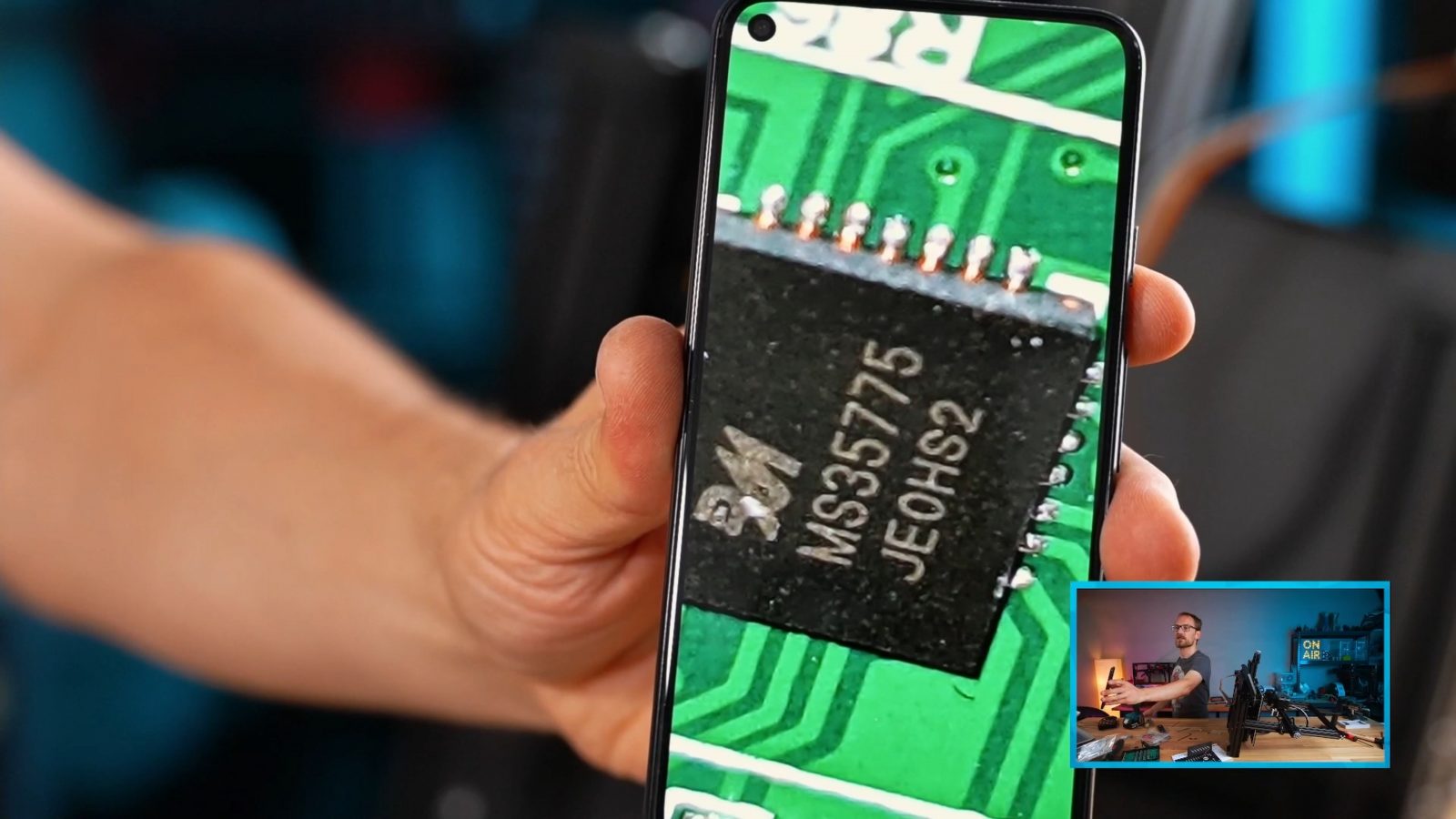

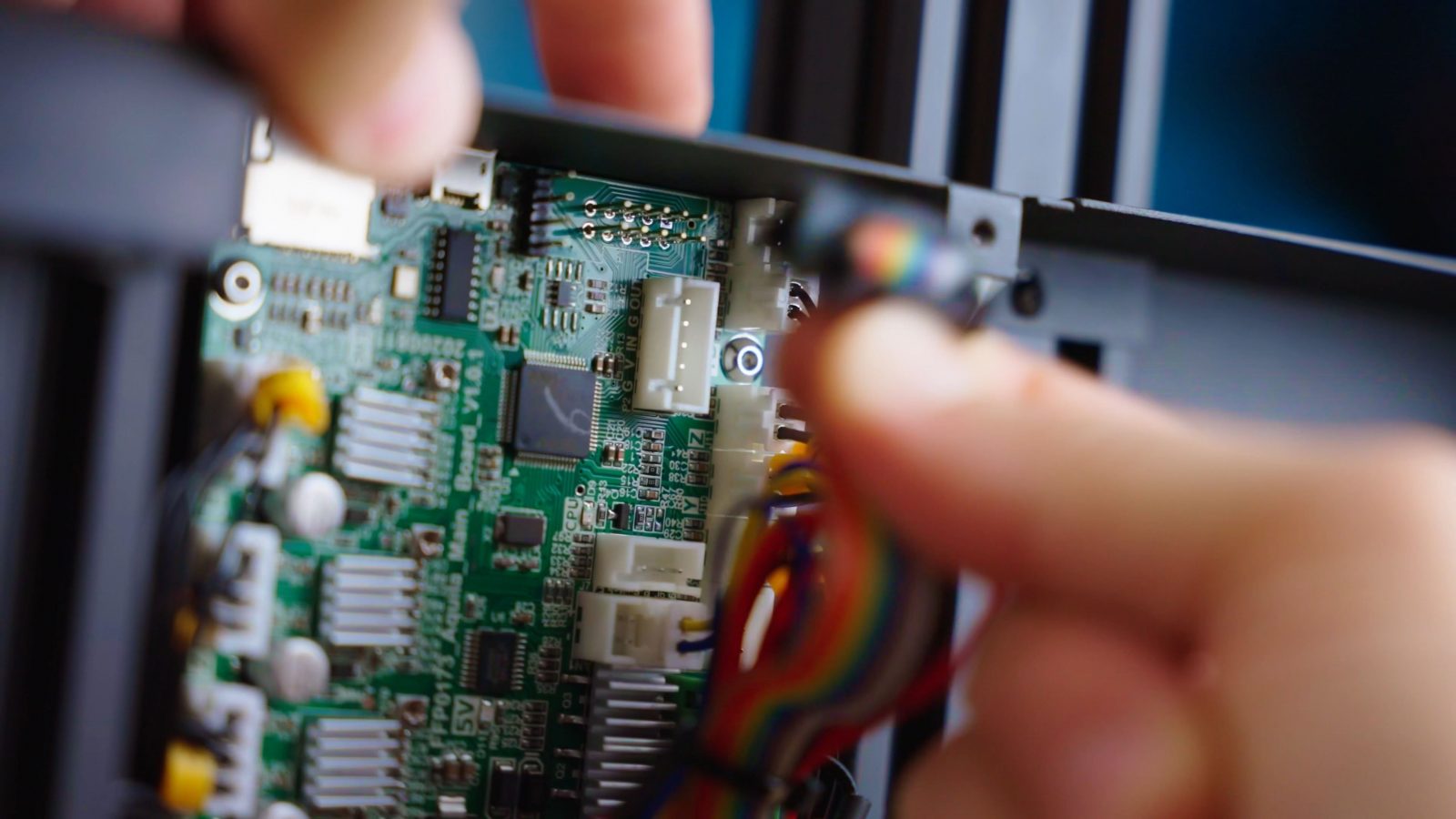

Electrics / Electronics

Moving on with electrical, while the mainboard does look fairly clean, in the unboxing livestream I casually pulled off one of the heatsinks from the knockoff Trinamic drivers and found a massive aluminum flake just wedged in there comfortably. I don’t think I need to tell you why having a sharp, conductive aluminum chip pressed up against the board and its components is not a particularly good thing.

Heated Bed

There’s still obvious design flaws, like the screw heads that hold down the aluminum bed, they stick out beyond the top of the aluminum surface and cause an airgap between the aluminum and the glass sheet.

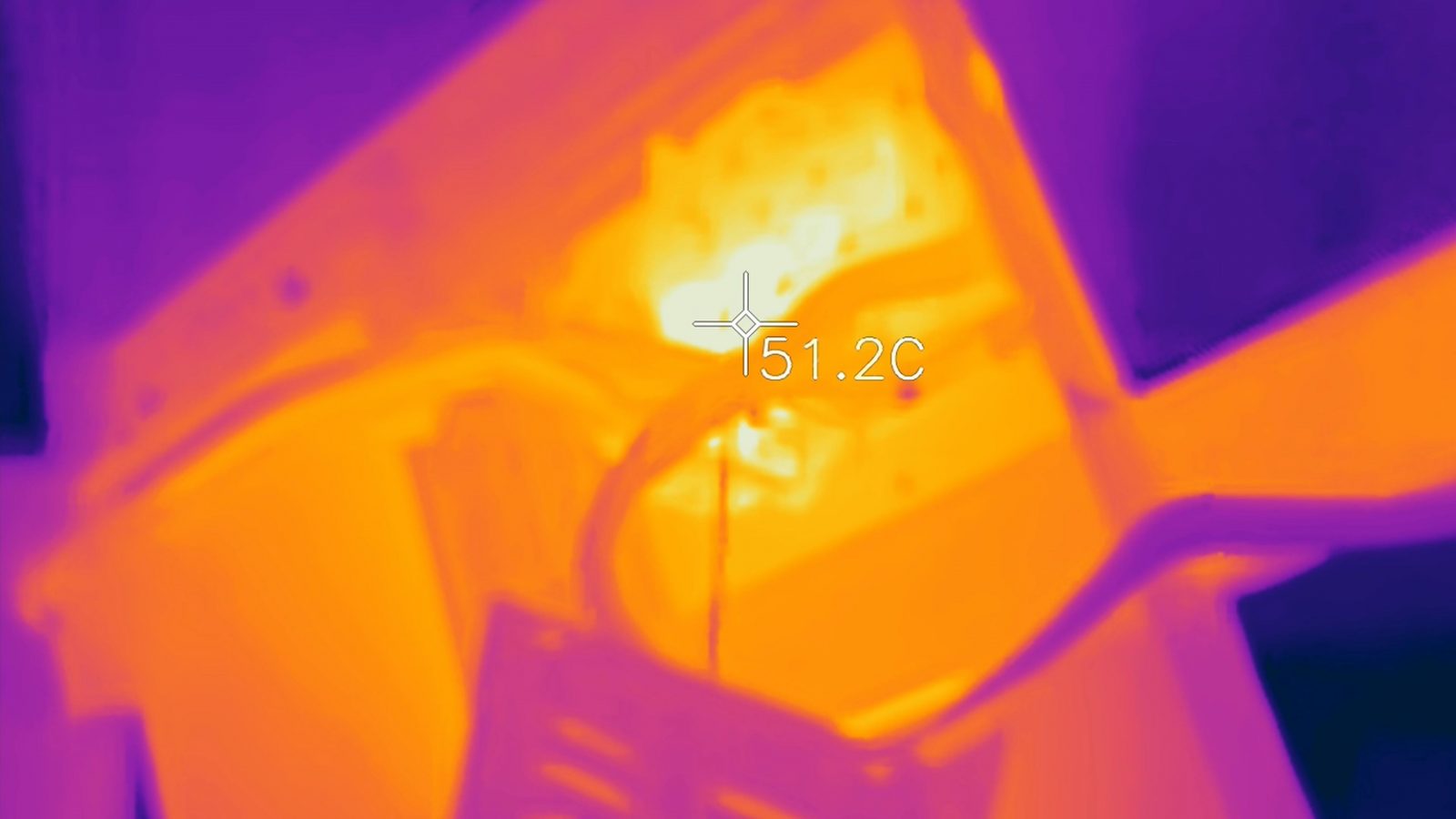

I did a whole video on how that creates huge issues for thermal transfer from the heater to the glass and makes especially the outside edges of the bed barely usable because they’ll be colder than the rest and more sensitive to being cooled down by the part cooling fan blowing over the bed. In the case of the Aquila, if we look at how much the bed manages to heat up over 20°C ambient, the center, where the clips press down actually gets 50% hotter than the rest of bed, which makes printing larger parts hard.

And it’s not something you can solve by just adding more clips, because the bolts are still sticking up and creating an airgap.

Thermal Safety

Oh, and these clips?

Well, they overlap with the electrical traces on the underside of the bed, and the chances are high that over time, they will rub through the insulating solder resist and short out some traces, which not only makes the bed heat less evenly, but also increases the current the bed draws, and that combined with the bed wiring wearing down over time, could be a bit of a fire hazard.

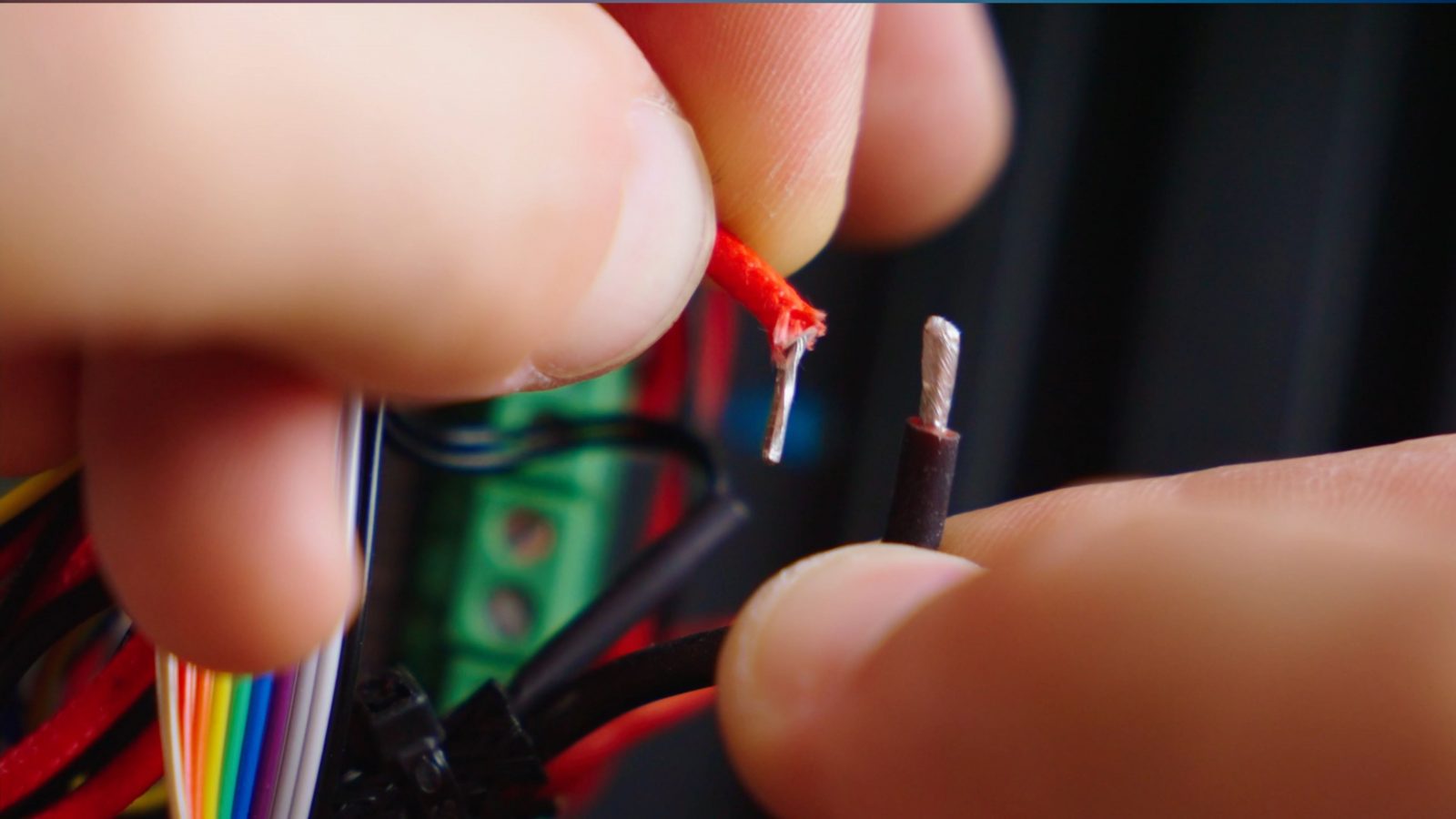

The mainboard and connectors stay reasonably cool, so that’s good to see, but they are tinning the wire ends of the heaters instead of using a proper crimp, so over time, that tin will flow out under the pressure from the screw clamps, which increases the resistance in that connector, and that that can eventually melt the connector or start a fire. Why?

But the most atrocious thing about safety on this printer is the thermal runaway protection that they actually managed to make worse than if they had done nothing. So thermal safety on a printer consists of a couple of things, and it all focuses around making sure that the heater elements won’t overheat. So the first one, and the Aquila is doing that perfectly, is checking that when it sends power to a heater, it actually starts seeing a temperature rise in the thermistor that’s measuring the temperature, so that protects against the thermistor for example falling off the bed. It’s just taped on in this case. So on the Aquila, huge alarm, full-screen message, perfect.

But the other two potential failure modes are the thermistor experiencing a wire break or an internal short. And both of those cases are easily detectable, and normally, if you don’t have any checks at all, only in the case of an open circuit would the printer keep heating. A short looks like it’s reading a super high temperature, so in that case the control loop would say “oh, I’m at temperature, I don’t need to keep heating”, so that would be fine.

However, in both of those cases, the Aquila just completely freezes up. The screen becomes unresponsive, there’s no alarm or anything, and it just keeps on heating. So I wanted to see what would happen to the machine in that case.

Thankfully, in my case, it didn’t burn down or melt anything, but there was a good amount of smoke from the silicone sock, and because there’s so much Teflon in and around the heater block, that would have definitely released a good amount of neurotoxins. I re-ran the test with a thermocouple hooked up and it got to over 330°C within 10 minutes. That’s with the thermocouple just wedged between the silicone sock and the block, so it probably got quite a bit hotter on the inside. You know, that’s not a room you want to walk into without some serious breathing protection.

The fact that the printer just freezes had me thinking that they tried to implement some sort of safety feature, but ended up screwing that up and now that code just crashes the entire thing. Like, sure, that can happen, no software is perfect, but Flashforge either didn’t care to test these safety features or intentionally decided to ship the printer anyway, knowing that this stuff wouldn’t work, and both of those options are unacceptable.

And no, “oh, it’s already fixed in a firmware update”, that’s not an excuse. This is how they shipped the printer. This is what they thought was acceptable. Most people never update the firmware, there’s no reminder in there or anything, this is how I don’t know how many thousands of people will be using the printer. This thing shouldn’t exist.

New Features?

Now, I could at least somehow see a reason for this printer to exist if it had some actual features that were, maybe, new? I mean, if we go through what Voxelab tout as new features, there’s print resuming after a power outage, I tried that, but when it resumed, the printer managed to knock over part of the print, lose some steps and basically ruin the part.

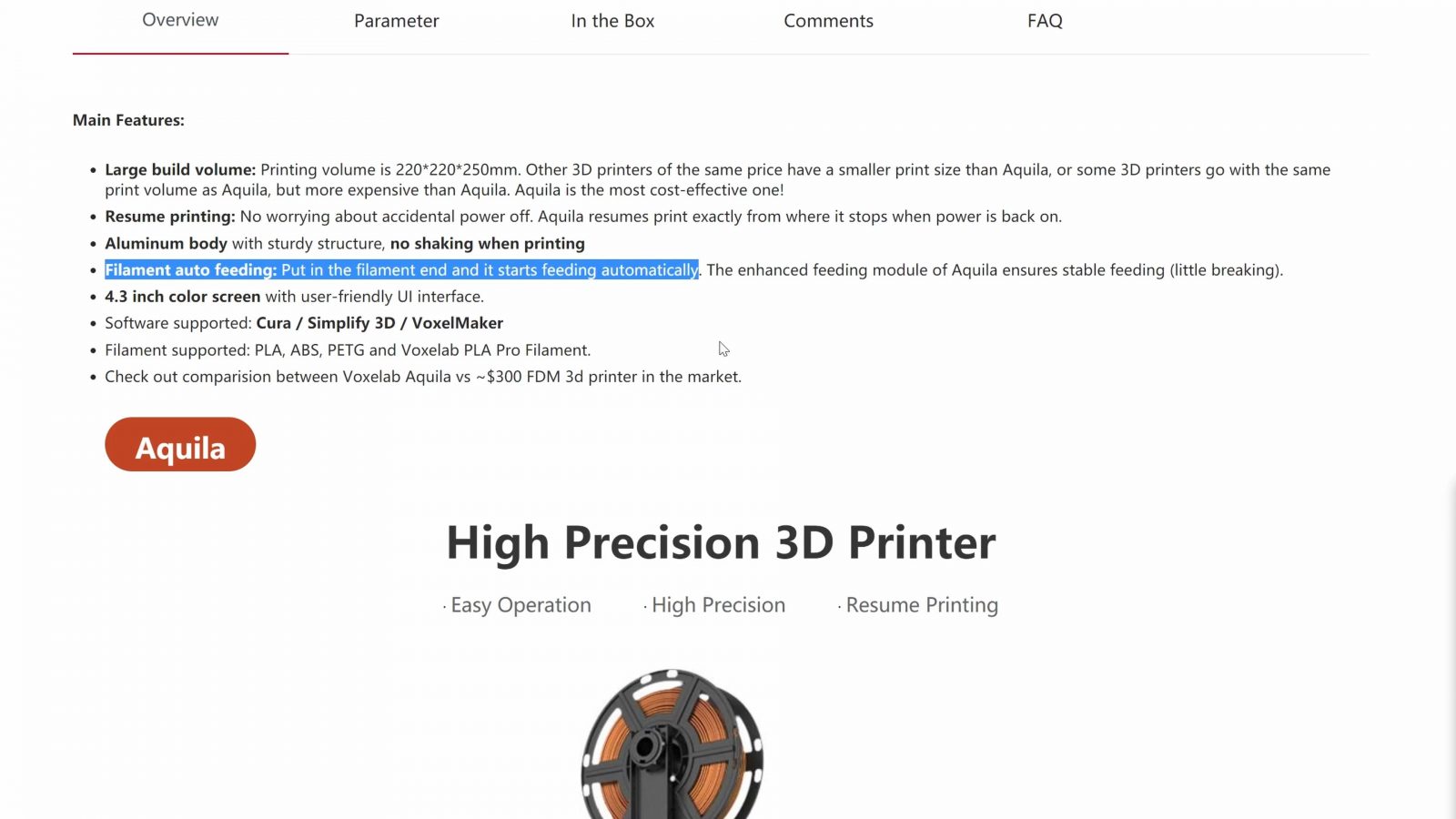

Then they’re saying there’s, quote, “Filament auto feeding: Put in the filament end and it starts feeding automatically”. Which is… a lie? This printer has no filament sensor, so loading filament automatically is something the machine is physically incapable of doing. They’ve got a menu item for the filament sensor, but it’s not actually on the machine.

Then, it’s claiming not just silent printing, but “Ultra-silent printing”, and to be fair, the stepper drivers are doing a great job of keeping the motion quiet, but the hotend cooling fan, the part cooling fan, the one in the power supply and the one cooling the electronics all add up to a sound stage that is anything but silent. It’s pretty annoying, actually.

Oh, and a big feature apparently is having belt tensioners. Like, true, it has belt tensioners, but it’s hardly a new feature.

One of the other things I saw them point out is that there is support for adding a BLTouch, and yeah, they did add a dedicated socket to the mainboard with the pins for a BLTouch, and there are two extra tapped holes on the toolhead, but that honestly sounds more like they intended to ship with some sort of a sensor, then cut that feature to save cost, but decided they could market the traces of where a sensor would have been as a feature?

They’re not exactly documenting how to enable BLTouch support, so the community has had to come in and provide custom Marlin 2.0 builds for the Aquila just to enable that.

My Conclusion

So what is this printer? I mean, they call it a “DIY” machine, but are they implying that it’s up to the user to make this work as a proper 3D printer? Because as Flashforge Voxelab sell it, it sure looks like it’s going to last just long enough for people to write their hype Amazon reviews or make a review video about it, and then after a couple of spools of filament, all the spots where they cut corners or simply screwed up design decisions will start to show. So, like at that point, you’re supposed to DIY fix and upgrade it? Which is fine, honestly, if you need a hobby. Lots of people, including myself, spend a lot of time tinkering with 3D printers, but then you’re not left with an actual tool that you can use for other stuff, the 3D printer becomes the stuff you work on.

Four or five years ago, when the Ender-3 was still fresh and it was a huge upgrade over the other standard budget 3D printer, the Anet A8, this would have been right up there. But in those 4 years, nothing substantial has really improved about these machines. And with this one in particular, even the stuff that has already been figured out is not on here. The hotend and extruder combo is absolutely bottom shelf. There’s no filament sensor. There’s no magnetic flex bed. Wire management is still bad. The fans and the way they run them is poorly done. Thermal protection is worse than it’s ever been. And overall there are too many design flaws and mistakes to be excusable. Now, it looks like that must have somehow become accepted, because if you check out the reviews on Voxelab’s site, all you see is 5 stars throughout. And it’s not like the Aquila is so much worse than all the other Ender-3 clones, but while things like smartphones are moving into the direction of being able to choose one by going over which one does the fewest things wrong, 3D printers seem to be moving more and more towards it being easier to list the very few things they do right. And that’s not a great spot to be in.

That’s not something that’s particularly unique to the Aquila, I mean all the other Ender-3s are “fine”, basically, until they break, but the more manufacturers keep pushing these unoriginal and unimproved machines onto the market, the less of a reason there is for them to exist.

One more uninspiring Cheeseburger

Originally I wanted to write this entire video in a bit of a different style where I would only talk about different fast-food cheeseburgers and the differences or lack of differences between them. Because honestly, it doesn’t matter if you get a cheeseburger from McDonalds, Burger King, Wendy’s, Jack in the box, etc, they’re all the same soggy, basic, uninspiring food item, that, yeah, provides you with some low-quality calories when you’re hungry, but does anyone really look forward to another borderline disgusting, basic cheeseburger when they’ve been eating the exact same thing for breakfast, lunch and dinner? I don’t. What about a Long Chicken, Royale with Cheese, Lé Big Mac, seasonal specials, vegan options, or maybe even trying an actual, properly-made burger for once? Instead, Cheeseburgers is all it is. And they’re fine. But not much more.

So thanks for watching, choose your burgers wisely. As always, if you enjoyed the video, give it a thumbs up and get subscribed or maybe even buy me a burger on Patreon or through YouTube memberships, but otherwise, keep on making and I will see you in the next one!

Disclosure (missed it in the video): The Aquila was provided to me free of charge by Flashforge Voxelab. Neither Voxelab nor anyone else had any say in the way the review was done and they did not see the review (or its script) before it was published. As always, no money changed hands. My full review terms https://toms3d.org/review-guidelines/

Get an Ender-3 v2 instead, maybe

💙 Enjoying the videos? Support my work on Patreon!

Product links are affiliate links – I may earn a commission on qualifying purchases (at no extra cost to you)

Check out my second channel “More Layers” on YouTube for livestreams

Check out the Meltzone Podcast (with CNC Kitchen)!

Product links are affiliate links – I may earn a commission on qualifying purchases (at no extra cost to you)