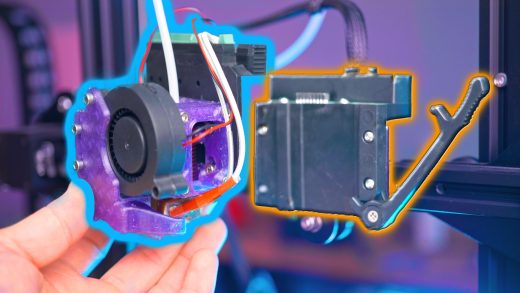

This is the WhamBam Mutant – patent pending. You just saw what it does – it’s a quickchange system for 3D printers and light-duty CNCs, be it with a routing head or something like a laser. You have one part that stays on the machine, they’re calling this the “Fixed plate”, and one part that stays with the toolhead, that’s the “Mobile Plate”, and they lock together with a pretty simple, but effective mechanism. They slide together with a dovetail and then it’s this lever that locks it all inContinue reading

Category: Hardware Reviews

Reviews of 3D printer components and accessories

Elegoo Mars vs. Mars Pro vs. Mars 2 Pro

Elegoo has really become known for their resin printers recently – but originally, they’ve been doing robotics and Arduino stuff. And that shows. In a good way. Today we’re going to take a look at their Mars lineup, specifically, the Mars, the Mars Pro, and the Mars 2 Pro. They’ve also got a cost-down Mars-C, and in the future, apparently, there will also be a Mars 2 non-Pro. But these 3 models are arguably the most popular ones they offer, so what I wanted to find out is what theContinue reading

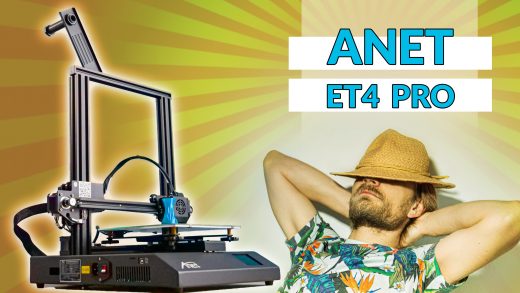

What a lazy 3D printer design! Anet ET4 “Pro” review

Here’s a little behind-the-scenes: Some of you might already know this, but I script all the videos where it’s reasonable to do so, for example for a review, I do my testing, write down notes, and then write a script from those. It just makes for more compact and easier-to-follow videos, I’ve found. Writing this review for the Anet ET4 “Pro” has been the most challenging scripting process I’ve had to do for a while because the things Anet are trying to get away with here are making a mockeryContinue reading

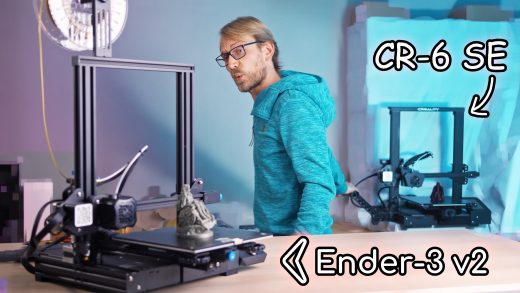

Creality CR-6 SE vs. Ender-3 v2

The Creality CR-6 SE. It’s an attempt to catch up to the big boys and to finally have something that’s not going to be labeled as “just another budget 3D printer”. But here’s the thing: The Ender-3 v2 is their actual budget 3D printer and it is actually doing a much better job at just about everything the CR6-SE tries to do. It’s more reliable, it prints better, it looks like a more professional machine, comes in 1/3rd cheaper and it’s a printer you can buy right now without havingContinue reading

Slice Engineering Copperhead Review

It’s been a while since I’ve reviewed just a 3D printer hotend without also looking at the printer around it – but that’s exactly what we’re going to do today. This is the Slice Engineering Copperhead, and I think it’s the first time a company is really serious about competing against E3D’s de-factor standard v6 hotend and ecosystem ever since that came out. But the Copperhead isn’t just a single hotend, it’s actually more of a set of hotend building blocks that you can use, adapt or leave out asContinue reading

First look at the Shaper Origin – a template router that needs no templates!

As shown in the video: dog paw svg on Flaticon Shaper Origin

Prusa Y-Axis upgrade

The MK3 is a really easy platform to upgrade – but does it need a 200€ HIWIN linear rail kit? Watch the video to see the process and results!

Interview One Click Metal

Let’s 3D print… with metals! There are a ton of options available now for producing 3D metal parts, but the most straightforward one involves laser-welding pulverized stainless steel directly into your final shape. No de-bindering, post-sintering or other steps necessary to get a fully functional part. And One Click Metal is working on making that technology a lot more affordable*!

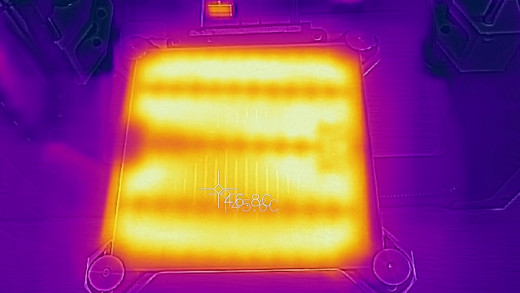

Testing 5 different heated beds!

No two heated beds are the same – in this video, I test which beds have the best chance of getting your prints to stick!