So this is the hot new product in 3D printing right now – it’s the E3D Herm.. Hem… Hemera. It’s the Hemera. It’s a hotend – extruder combo that I think does pretty much everything right. So let’s check out what’s new and what’s different compared to what else is out there.

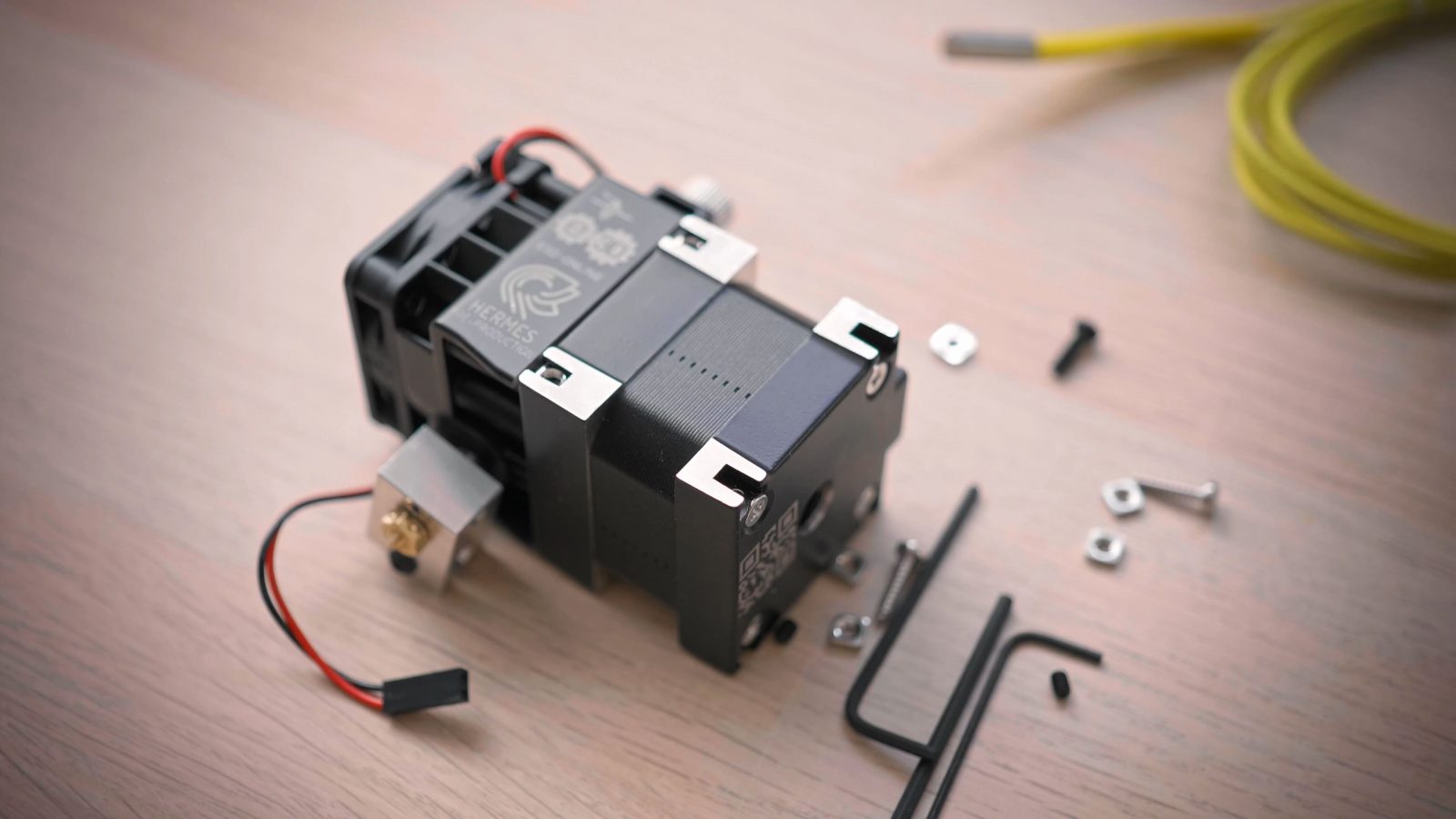

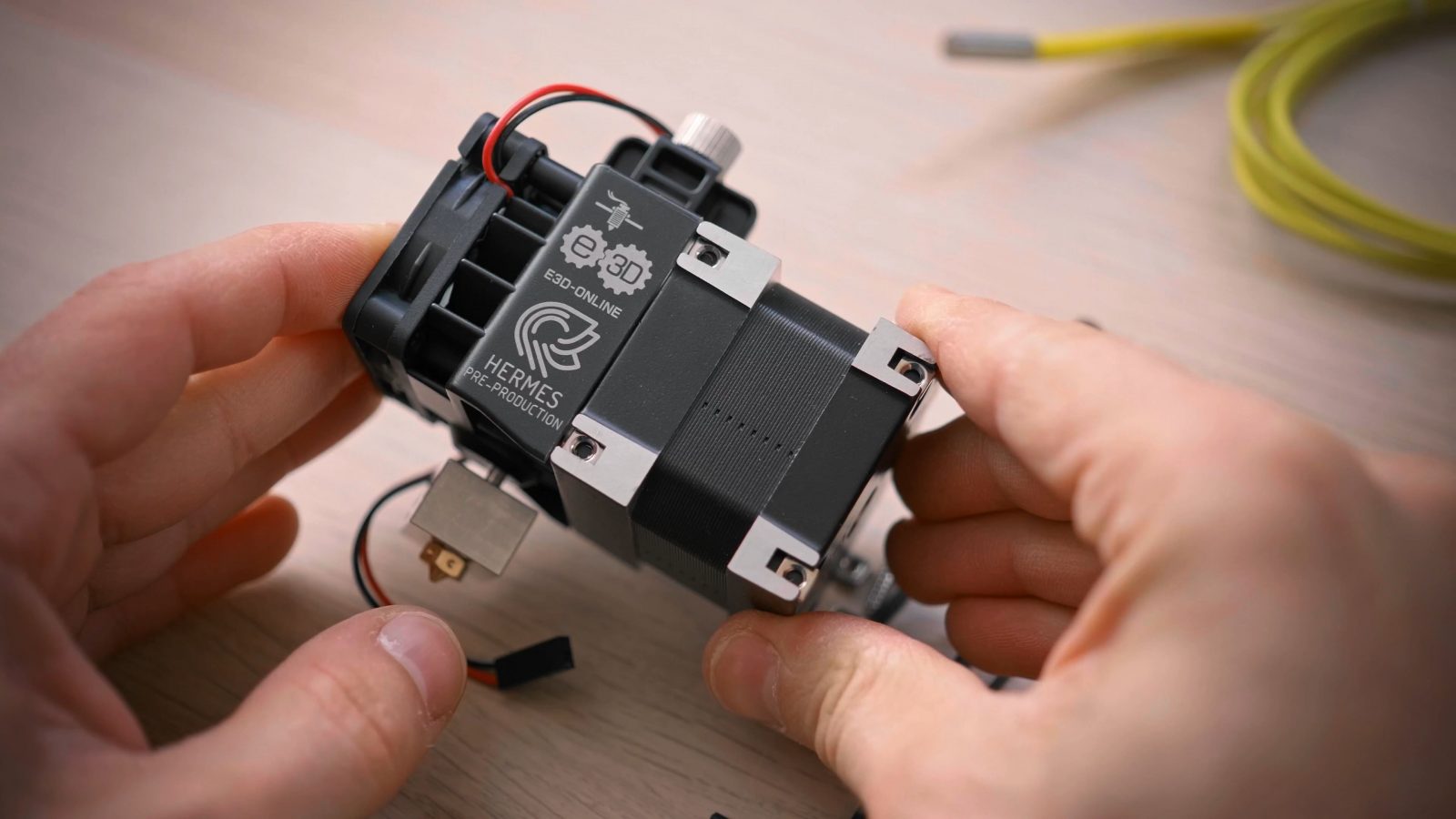

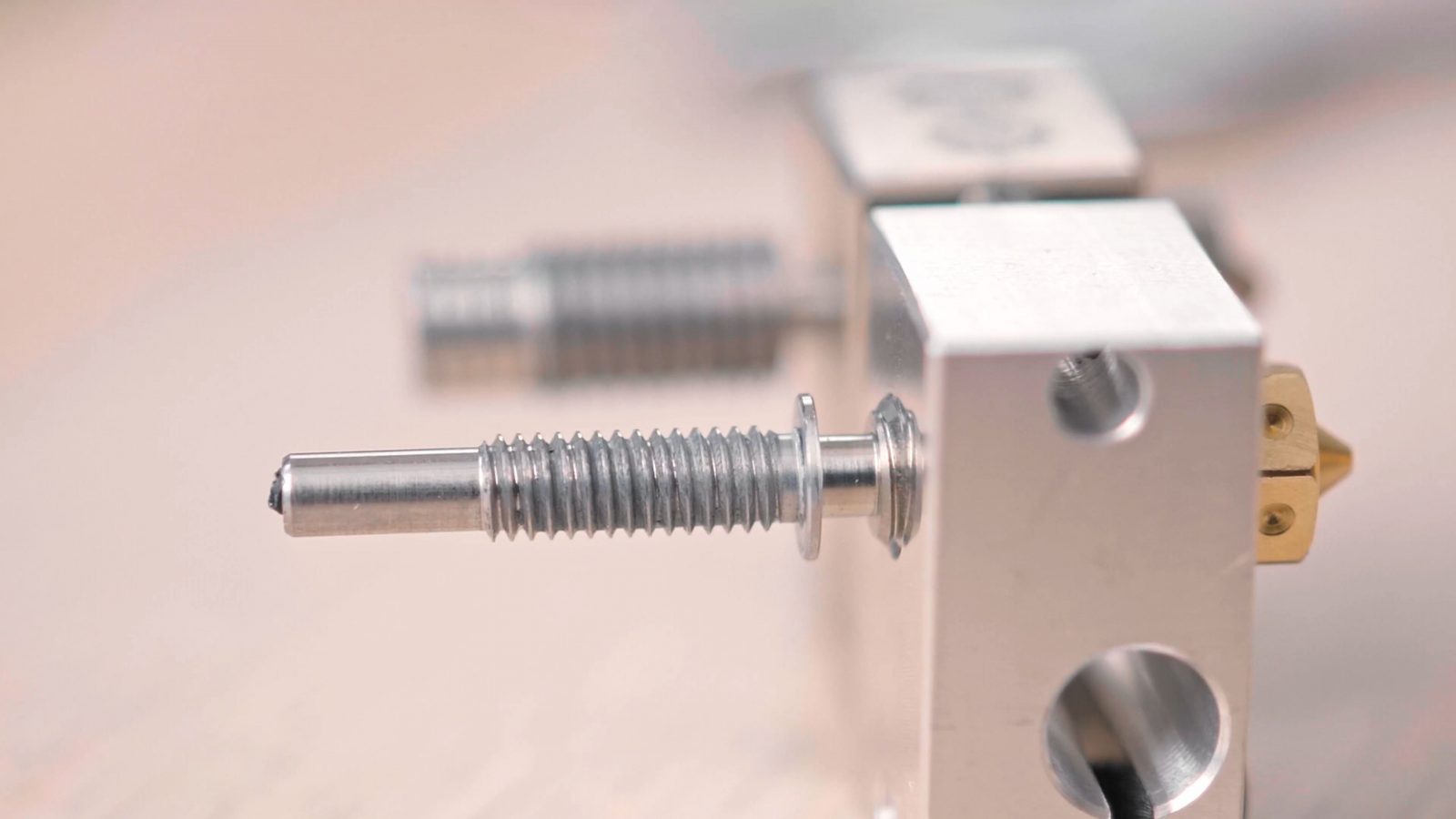

Okay, the biggest and most obvious new thing with Hemera is that it really is intended to be used in combination with the included v6 hotside. In fact, you can only buy it with the v6 hotside or as a Bowden version, which is just taking out the hotside and Hemera-specific heatbreak and replacing it with a Bowden adapter, aka the Bowdapter, and you obviously don’t need the fan anymore. But the nice thing is, instead of having an extruder body that you use with a hotend and a stepper motor, it’s all combined into one group of parts. The front plate of the extruder is also the heatsink for the hotend and the stepper motor’s covers do double duty as the backplate of the extruder and as mounting points.

That makes it super compact as a unit, but also shortens the filament path between the extruder gears and the nozzle by quite a bit. That helps extruder precision, there’s less wiggle room for the filament to “coil up” or just compress and act as a spring, which compared to an average extruder lets you lower retractions slightly, gives more accurate extrusion, but also lowers friction, which you really need for flexibles. And it does eat through flexibles like a champ, there’s nowhere the filament could escape to, either because you have that Hemera-specific heatbreak go right up to the extruder gears and that’s flanked by the aluminum casing on both sides.

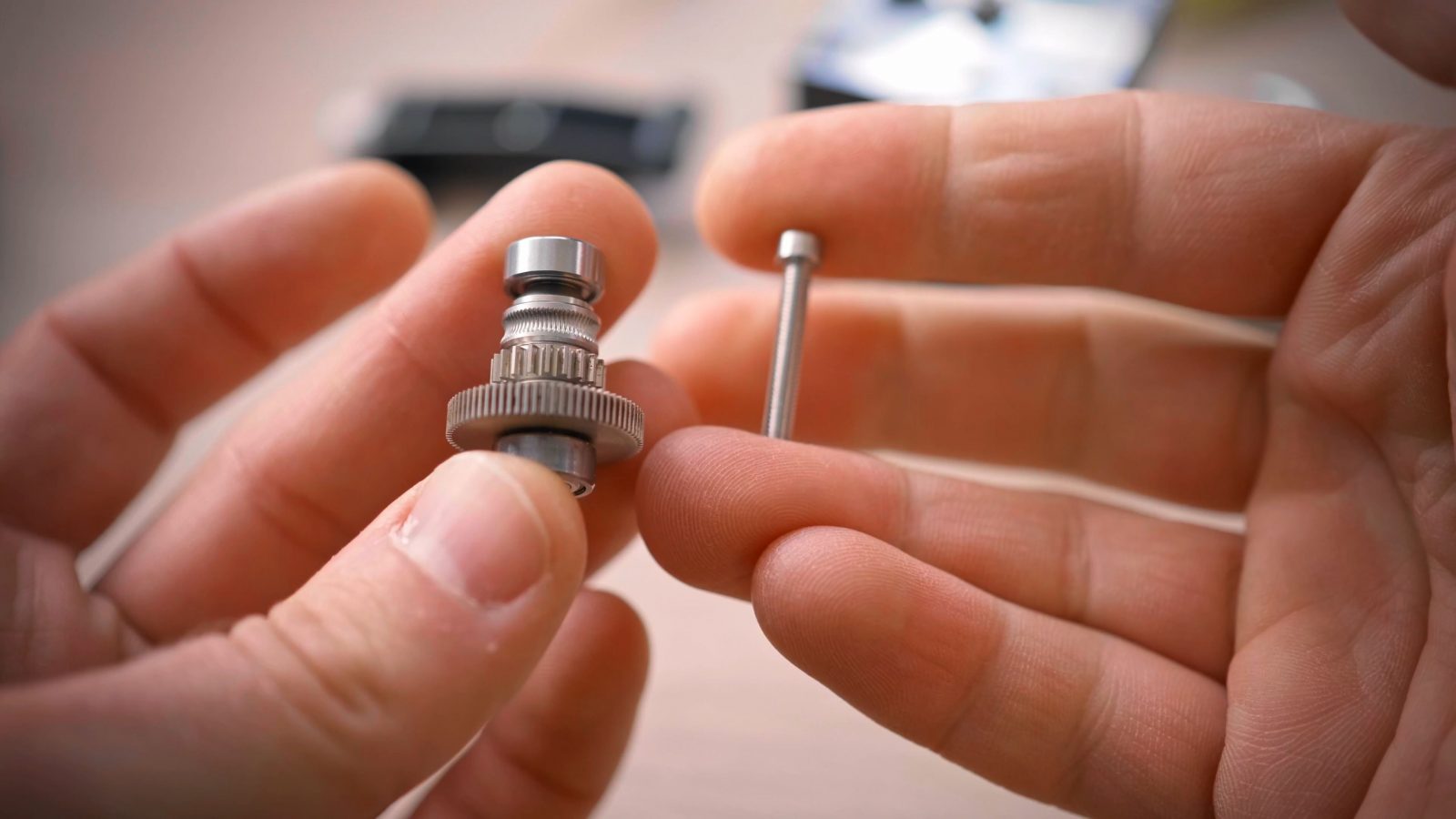

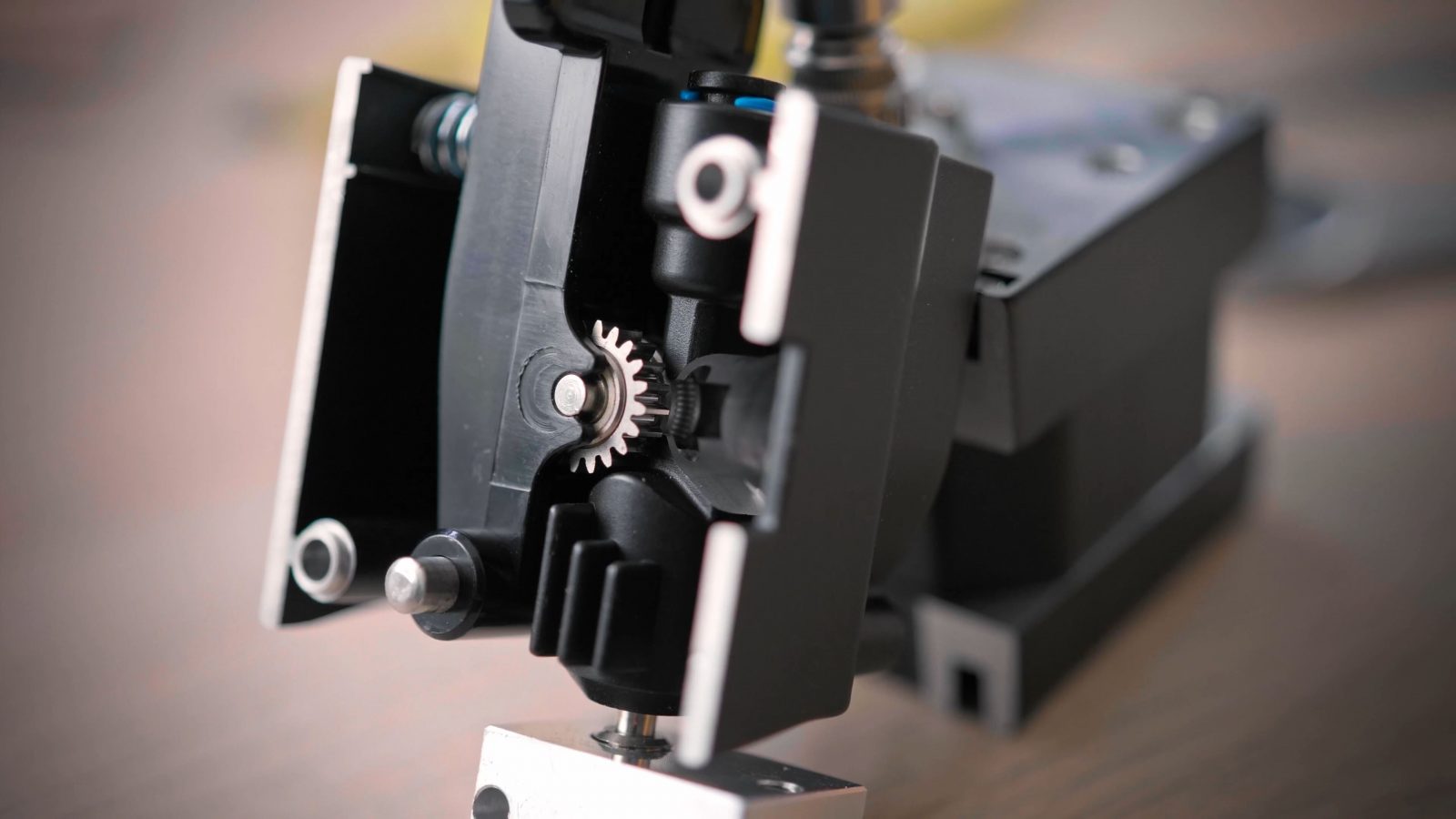

And yes, it does have extruder gears… three of them. The pinion on the motor shaft, the first extruder shaft with a larger spur gear for that three-to-one gear reduction from the motor, the hobbed section and a second spur gear to transfer the torque to the second extruder shaft, Bondtech style.

By the way, there’s a nice little IGUS bushing on the iderl. This is all pretty well miniaturized stuff, I mean that first extruder shaft is just pretty much crammed full with parts, and the reduction gears look pretty miniscule, and *gasp* is that a broken gear already? I only used this Hemera for a few kilos of PLA so far. Yes, yes it is. But this is also the pre-production Hemera unit, and this exact issue where the pinion cracked was discovered and fixed before the retail units were produced. So, yeah, that’s why you do testing with your products.

Anyways, so the extruder part is basically a Bondtech BMG. I don’t know exactly which hob profile the BMG uses, but the one in the Hemera is really close to an M3 thread, but without the thread pitch.

That’s on the fine side, which means there’s going to be little to no pulsation from something like a coarser spur gear chunking against the filament, but I’ve also found finer hobbing to have less of a “self-cleaning” effect, that if you ever strip your filament from a clogged hotend or messed up print settings, those shavings may not fall out on their own again, but then again, with a dual drive extruder, you’re probably never going to end up with stripped filament anyways. And I don’t even remember when exactly I last stripped filament, even with single-gear extruders. E3D also say that before running out of grip on the filament or breaking the spur gears, the motor should run out of torque and just skip a step. I hope I remembered that correctly.

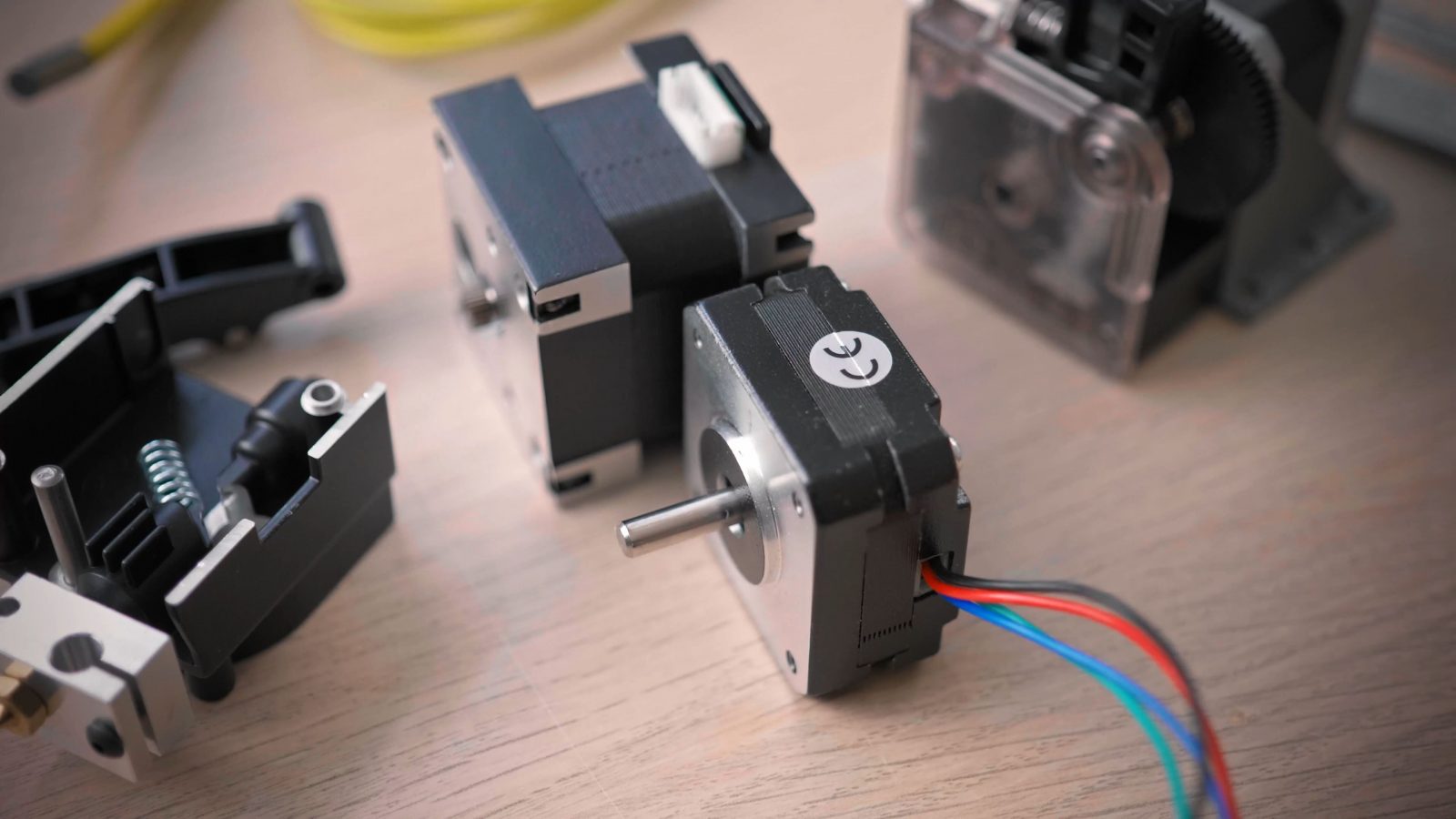

Speaking of the motor, the one that’s, well, not included with, but built into the Hemera is a compact-size one. It looks bigger and heavier than it is, but I’ve still not managed to run out of torque with it, with the normal v6 hotside or with the Supervolcano, even printing beyond what would be considered “reasonable” speeds. A lot of you have already asked for a pancake version of the Hemera, I guess that might be inspired by my E3D Titan review from back in the day where I specifically used a pancake motor with the Titan and got a perfectly usable, lightweight setup.

With the Hemera, I believe you could swap the end plates onto a normal NEMA 17 stepper, but the shaft on the Hemera’s motor is turned down and has the pinion gear pressed on, so that right now keeps you from using your own motors and we’ll have to wait whether E3D release a pancake version some time in the future.

Currently, it weighs in at 381g, including the hotside, fans, wires, all that, the Anet A8’s stock extruder and hotend were 397g, that one does not have any gearing and is only a one-sided drive extruder and E3D’s previous Titan clocked in at about 366g, so a few grams lighter than the Hemera, and while the Titan was geared down, it was not a dual-drive unit, but the motor I used on here is already of a very comparable core size to what’s used on the Hemera. The motor on the stock A8 extruder is a bit larger, though.

So weight-wise, it’s par for the course, it’s not super light because a lot of the parts are made from metal, but it’s also not extraordinarily heavy.

When it comes to how you can mount it to your specific machine, you get M3 nuts on two sides of the Hemera, for most printers that works really well.

I’ve made mounts for the Raptor 2.0 and for the Anet A8, there’s also mounts for a ton of other printers already available thanks to E3D actually reaching out and sponsoring people to create these mounts and full mod guides, 3DMakerNoob has done a bunch of them, and yes, the Anet A8 guide was also sponsored, but I guess I don’t need to point this out, but this review is entirely my own experience with and opinion on Hemera.

So why don’t we get to the some of the points that I wish were better?

Okay, first off, the heatsink and fan that cool the hotend. Typically, this would be that blue fan shroud that kind of blows air parallel to the bed, but the fin structure on the Hemera was designed specifically to kick air up and away from the bed and the nozzle.

Now, while that’s great for printing hotter materials that want as little airflow as possible on the print itself, it also means when the Hemera is mounted like this, it blows right in your face and your eyes when you’re standing in front of the printer. I guess a little airshield that funnels air upwards could fix that.

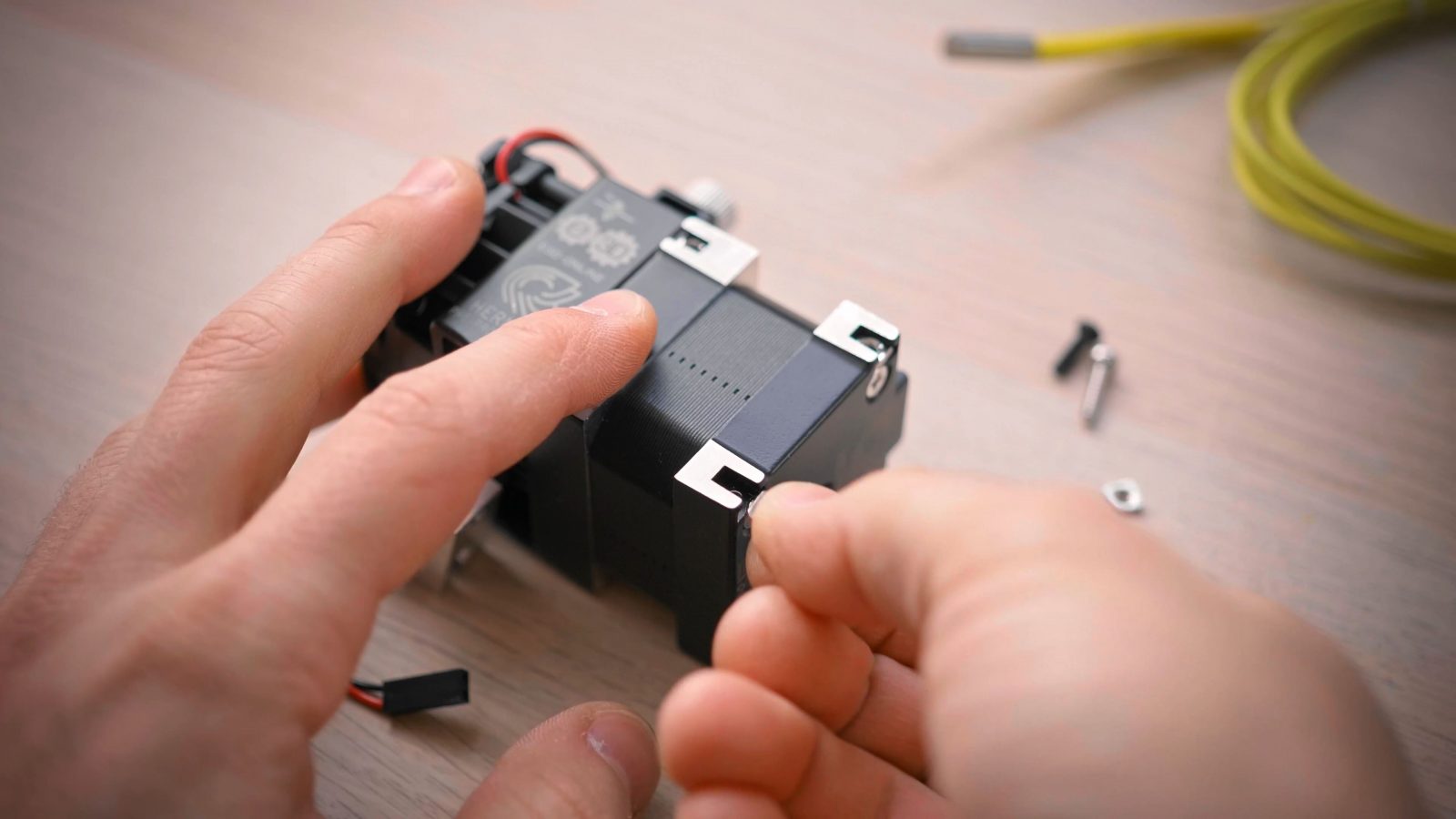

Next, the tension adjustment. So they’ve got this really cool injection moulded idler lever in here and you can really tell that E3D have learned a lot about injection molding since their first dabs into it with the v6 fan shroud.

So it’s got this slidey ramp setup that as you tighten this screw up top, it actually pushes this white bit out to the side and increases tension on the idler spring. And it’s a mechanism that does work well, but there is no indicator of how tight you actually want to set it.

Titan had this peephole that showed you how much tension you’re putting on the filament, on other extruders, for example the MK3’s, you at least see the point where a screw is flush with something and that gives you some reference, but here it’s just this white bit being flush with the lever at some point and from there or from bottoming out you can count the turns on the adjustment screw, there’s easy way to tell what level of tension you’re at. I don’t know, at least have some steps in the backside of this white piece that indicate a few different tension levels.

And lastly, it’s yet another proprietary set of parts for the extruder. I know there’s no way around that if you want to advance performance, you kind of need to cut some ties, but yeah, the entire stepper motor is now a proprietary part, as is the heatbreak, it’s another Hemera-only part.

For now. Let’s see if this style gets adopted for more setups, because really, I don’t see any reason why the old v6 heatbreak would still need to exist. Actually, when it comes to thermals, the Hemera heatbreak should outperform the v6 one since the heat needs to travel through less stainless steel.

So, are these strong arguments against the Hemera? No. It’s details. E3D do know what they’re doing, and I they’ve definitely achieved was seems to have been the two main improvements over the Titan line of extruders: First, to make it more compact, and that’s definitely happened, especially because now there’s nothing sticking out from the sides and nothing that needs to be accessible from the sides, so you can mount it flush both ways, or you can even put these right next to each other – and it looks like there’s a mirrored version coming up, too, the front plate already has all the holes and stuff provisioned for that.

And the other goal was price. Now, that was achieved by integrating everything into singular, albeit proprietary die-case parts and just straight up bundling a v6 hotside and a motor with it. And honestly, I feel really bad for Bondtech, they were the ones pioneering dual-drive extruders, and now E3D come in and they’re just better at making the same level extruder for much, much cheaper. So I’ve taken the prices of Matterhackers because they carry everything, so I have some comparable prices. All the links are in the video description below. The Hemera kit is $120, which is more expensive than the $99 the Bondtech BMG is currently selling for. But with that, you still need a motor, which you can bundle for an extra $15 and you need a hotend, the BMG is just the extruder itself, and a regular v6 hotend is another $59. So that leaves the Bondtech BMG costing basically 50% more for a comparable setup parts-wise, but it’s got a much longer filament path, and of course that also means that it’s physically a much longer setup and probably heavier, too.

I mean, that makes it kinda tough to recommend the BMG at this point. The BMG used to be the benchmark for compact, lightweight, high-performance, but I think it’s found its match.

E3D have done an excellent job with the Hemera, not just with the product itself, but also with having official mounts, firmwares and guides ready to go for all the popular printers basically on launch day.

This right now is the setup to beat. From what I’ve seen performance-wise, like actually printing with the Hemera, it’s flawless. This thing never skipped a beat. Now, I haven’t measured how much force these extruders can exert on the filament, let me know if that’s something you’d still like benchmarked, but really, if any extruder is going to compete with the Hemera right now, it’s going to have to be on price, or maybe on form factor, but not on performance.

Hey, one quick favor to ask – could you check if you’re subscribed? Because I still see that a third of you are watching and apparently liking my videos, but you’re not subscribed. Now, YouTube isn’t even going do much based on that subscription unless you also set whether or not you want to see notifications, you can do that by clicking the bell and choosing, well, whatever setting you like. So thanks for subscribing, and also a big thank you to all my awesome Patrons and YouTube members, on YouTube right now you can join for 5 bucks a month and that gives you access to supporter-only Q&A hangouts.

Thanks for reading!

Get the Hemera here:

💙 Enjoying the videos? Support my work on Patreon!

Product links are affiliate links – I may earn a commission on qualifying purchases (at no extra cost to you)

Check out my second channel “More Layers” on YouTube for livestreams