This is not a cheap 3D printer. It’s a very affordable 3D printer – but unlike filament-based printers, the story doesn’t end there. So while the Elegoo Mars is an incredible, high-detail resin printer, you can’t just it to any other machine that costs under 300 bucks. So today, we’ll look at whether Elegoo are actually managing to democratize printing or if you should just stick to FDM.

For some reason, when Elegoo introduced the Mars for around 280 bucks, the internet just went crazy over it. But it’s not like the Mars did anything really new and there were already machines like it out there. Even in a very similar price bracket, depending on which machine was on sale at what time. My experience has mostly been with FDM so far, filament-based printers, but I did have a Wanhao Duplicator 7 SLA printer for a good while now, and even though it seems to be practically the same machine as the Mars, I never really managed to warm up to the Duplicator 7 for many different reasons. So my take on the Mars is going to be from that perspective, too. And I do actually like the Mars a lot more than the D7.

But let’s start out with the specs, and they, too, are going to sound very familiar. At its core is a 5.4” 1440p smartphone screen that gets you a 12 by 6.8cm print area with a 50µ pixel size. The Z-Axis does 15.5cm, which I think is more than enough for the build area – when you’re printing busts and stuff, you’re mostly limited when it comes to how large you can scale them up by the 6.8cm maximum depth.

Now, the resin the Mars is printing with cures through quote-on-quote UV light, but technically, the 405nm wavelength is deep blueish purple and not UV, you definitely won’t get a sunburn from it. So inside the printer, there’s a large UV LED in the bottom that shines through that LCD screen, the LCD masks all the areas that shouldn’t get exposed and cured and than with every layer, the print surface just moves up a bit, lets some fresh resin flow under it and then cures the next layer below the last one. This printer actually prints all your parts upside down, but you can just flip them once they’re done.

One of the great features of the Mars is that it has a touchscreen interface and a USB port built right in. With the early cheap resin printers you’d basically run the masking LCD directly as a second screen from a computer, which was just horrible. If you’d leave your mouse cursor on the wrong screen, you’d actually get just an extruded mouse cursor column just printed next to your actual part, the computer couldn’t go into standby, windows update messages would screw things up, you know, the whole deal. Here, you just save your print file to a USB thumb drive and the printer handles the rest.

So let’s actually have a look at a few prints!

So, what did you see there? The yellow prints were done with Wanhao resin, the clear and grey parts were Elegoo’s own resin. And there is a massive difference between the two. I was never happy with the Wanhao D7, possibly because I only ever used the Wanhao resin with it. The prints with Elegoo resin on the Mars are clean, crisp, detailed, have only minimal warp, while the prints with the Wanhao resin warped a lot, supports broke off during the print and actually, I could never get the parts to fully harden and cure, even leaving them out in direct sunlight. These still feel tacky and soft, even after two days of curing. When I did the exact same thing with the parts printed from Elegoo resin, they actually turned pretty brown. What I’m told is happening here is that the partially cured resin, as it comes directly off the printer, instead of curing to a clear, strong plastic, actually breaks down from the more violent UV rays that are a natural part of sunlight – the same ones that give you a sunburn. Supposedly, once parts are fully cured under the “normal” 405nm light, they are much more UV resistant and won’t turn brown as much anymore, which is why I’m building a curing station with these mains-powered 405nm LEDs.

Overall, the print quality from Elegoo Mars is damn impressive. I don’t think I’ve had a print actually fail with this printer yet other than when it was clearly my fault for for example not setting the bed correctly, they’ve all come out looking really great. The only thing that stood out as artifacts are these lines that appear every now and then, I have no idea what they are. But overall, detail is great, reliability is great and resin prints just always look fantastic.

But of course, that comes at a price, not just that you can’t really observe the print as it’s happening like with filament printers, but the fact that you’re working with resin.

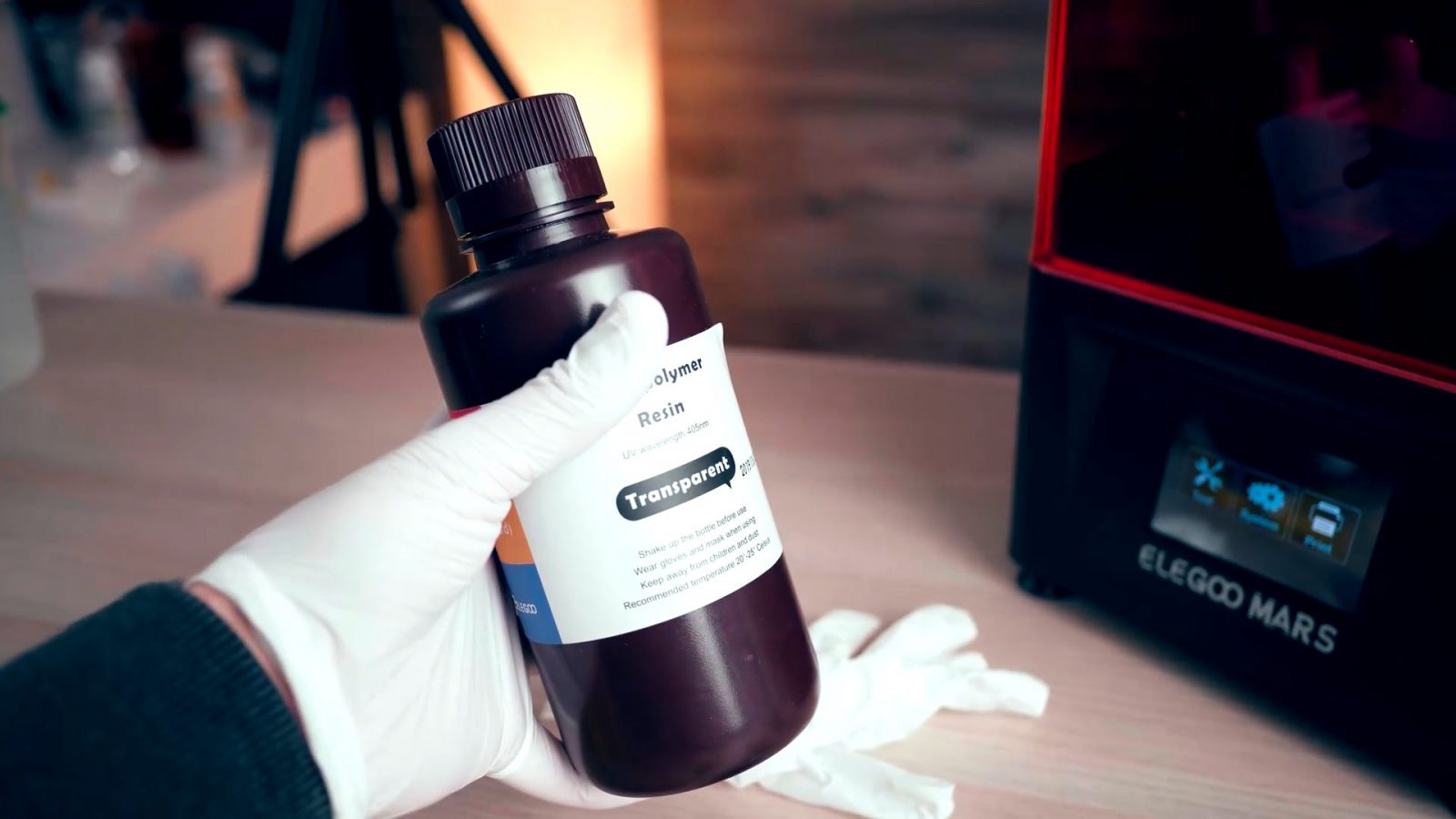

Resin itself is nasty stuff, first of all, it’s a sticky liquid, that, with this setup, you will inevitably get on your gloves that you’ll of course be wearing when using the printer, that’s why I don’t have a ton of footage of actually using the machine, because as soon as I put my gloves on and start working with the printer or the parts, I don’t want to go back to the camera with those same gloves and start smearing resin over it. I mean, if you try, you’ll barely get any of the stuff on your gloves, but you never know for sure. And why wear gloves in the first place – some people seem to think you don’t need them? Because resin is really nasty stuff. It’s not necessarily “toxic” in the classic sense, but it can screw with how your immune system works and give you chemical burns. Which look horrible. You definitely do not want to get this stuff on your skin, definitely not repeatedly, or in your eyes, depending on the resin you should also be wearing a respirator with an organics filter, and that’s not just me saying that, it’s literally in the material safety datasheet from the manufacturers.

There are a few newer resins that either don’t smell… as much, or human noses just don’t pick it up, the Wanhao stuff smells horribly, the Elegoo resin is a bit less smelly, but compared to printing PLA, it’s still really bad. I’ve actually installed a fresh air ventilation system here in the studio with an ERV so that I could use these resin printers at all. With the fumes just lingering in here, my throat would start aching and my nose would start burning, so really not something you’d want in your living room. There are also “plant based” resins now, but as always, just because something is “natural” doesn’t really mean anything, the resin is still nasty stuff.

And of course, the prints right out of the printer aren’t usable straight away. With a filament printer, you just reach in, pop the print off the bed and that’s it, with resin printers you at least have to wash off the resin from the surface of your prints, typically you do that with isopropyl alcohol or any other organic solvent. Just like with the “plant based” resins, there are now some resins that are water washable, but you still can’t do that in the sink like it’s implied, because with both water or IPA, you can absolutely not pour this stuff down the drain once it’s contaminated with resin. This is essentially hazardous waste.

Okay, and once you’ve washed your parts you still need to fully cure them, because they will at least be somewhat tacky still on the surface and sometimes even still soft all the way through.

And all this combined makes it really hard to properly compare filament printing to resin printing when it comes to cost and effort, because for resin printer especially, the printer itself is just such a small cog in the entire setup. Once you add up accessories and consumables, you’re easily spending another hundred or more bucks on top of the printer itself.

The resin itself is actually, I’d say, very reasonably priced now, these half-liter, roughly 500g bottles of Elegoo resin are 25€ and you can get them Prime shipped; and considering you’re not usually printing large, chunky parts completely solid with these resin printers, that’s actually not too far off from what filaments costs. It’s still more expensive, but very reasonable for being a less commoditized material I think. On the other hand, I’ve probably spent as much on nitrile gloves as I did on resin.

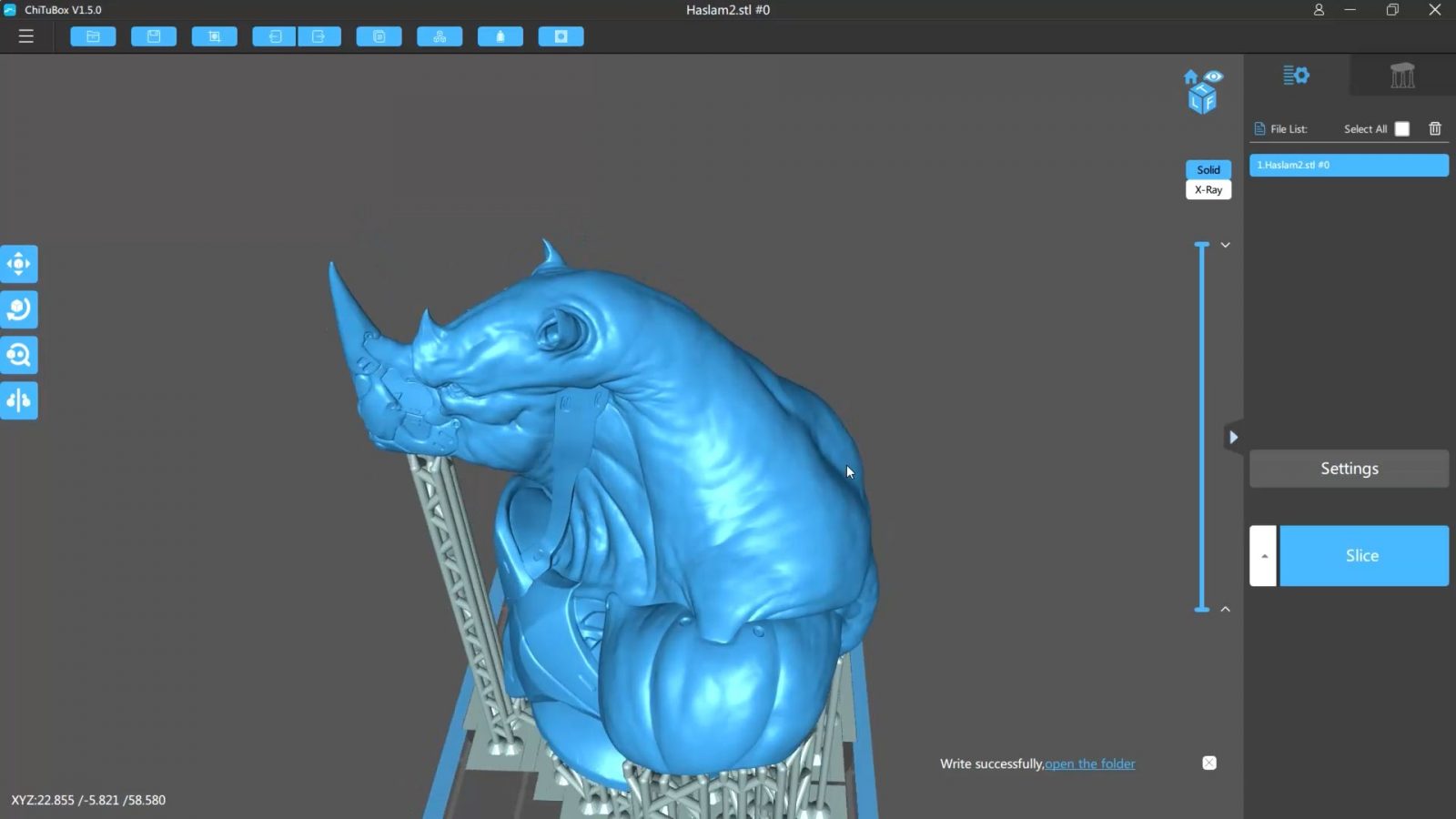

Speaking of parts that are hollow – the software. And I’m actually pretty happy with it! What Elegoo are recommending is ChiTuBox – which is a closed-source software that’s definitely not GDPR-compliant, that you can use for free for non-commercial purposes. There’s no option for anything but private use – yet, but down the road it looks like there will be a paid ChiTuBox Pro version with, quote, more features. The good thing is, it comes with a profile for the Mars that works really well out of the box – unlike the Wanhao D7 where I had to manually set up one of three different profiles in their software and none of the ones they suggested was actually “correct”.

In ChiTuBox, you can add supports, automatically or manually, tweak your basic print settings, rotate, scale, align parts, all the stuff you’d expect. You can also hollow out parts like this bust that don’t need to be super strong and would just use a ton of material if you’d print it solid. I think that’s a pretty neat feature, but I still need to figure out the best way to then add holes so the resin that’s trapped inside the part can actually escape. With the parts that I’ve been printing hollow, the holes were often too closed up after a print and I’d have to manually peel them open, and even then there would still be uncured resin stuck inside the part forever. It’s probably best to have three or more holes in opposite corners on a hollow part so that you can properly wash the inside, too.

The hollow feature sometimes struggles a bit with models that have multiple intersecting shells, so with this one, I first combined the bigger shells in Meshmixer and after that, it worked fine. And again, look at that print quality!

Okay, back to the printer: Build quality is very good. There’s no Z-wobble, the parts feel solid and even the resin container, the vat is a heavy chunk of milled aluminum.

Elegoo also offer a 4-pack of plastic vats for a very reasonable price, and I think it’s basically a must-have if you’re printing with more than one type or color of resin. Cleaning out the vat just to print with a different resin is really not fun, and in this one that has the clear resin in it right now you can still see some leftovers from the yellow Wanhao stuff even though I cleaned it out as well as I could.

The printer is also quite loud during use – and the only source of noise is that fan that cools the UV LED in the bottom here. It’s always on and it’s definitely noisier than a quiet filament printer, but maybe a fan swap can solve that. Then again, you probably don’t want to be in the same room as the printer anyways because fumes.

And two more things on the topic of the UV LED – because apparently the Mars only uses a simple reflector to “spread” the light from the LED over the entire print area, I’ve been told that you can run into issues where the center actually gets exposed more than the edges of the print area, but I’ve not run into that; and supposedly the LCD screen used in here can or will fail at some point due to the near-UV light. I’ve heard anywhere from 1000 hours – which would be after just a few bottles of resin – to tens of thousands of hours. Just something to keep in mind, the screen may be a consumable, but thankfully, the actual screen part itself is only 30 bucks in materials if you can manage to swap it yourself. If not, well… too bad.

And of course, the LCD is right under the print surface, so if your Mars is missing that one retention screw like mine did, the aluminum bed will shoot straight down towards the LCD when you level the build plate for the first time.

It’s a quality control issue that shouldn’t happen, so check that your printer has this screw right here installed before you loosen the bed for leveling. But other than that, the leveling mechanism is actually pretty simple and effective.

The actual touchscreen LCD is right up front and makes the printer easy to use, there’s everything on there that you’ll need to run the Mars, you even get small thumbnails of the print you’re about to start, but the USB port is on the back, which, just like the Ultimaker having its spool mounts on the back, is kind of inconvenient.

So is the Elegoo Mars a good 3D printer? Yes. I’m really happy with it, but then again, it feels like a resin printer itself shouldn’t be hard to get right. I know everybody likes car analogies, so just comparing different resin printers is like comparing different car engines – it’s definitely the core part of a fossil-powered car, but there’s so much more to a vehicle than just the engine. Like, this is a good engine, but that’s all it is.

So, really, a good system for resin printing should also factor in some way of cleaning the parts, resin handling, which Elegoo actually does comparatively well at with the VAT packs, and it should also include a way to correctly cure parts. That makes it hard to compare a resin “printing engine” with a filament printer where you don’t really need anything else but the printer itself to produce parts.

But still, if you’re looking for just a resin printer, the Mars is a super solid choice right now. And if you’ve been watching my stuff for a while, I’m very cautious with saying something is “the best” one, because I usually haven’t thoroughly tested every single other machine there is, but this is definitely the best one I’ve ever used. Sample size 2.

So thanks for watching, let me know in the comments what your take is on resin printers – too much hassle? Totally worth it? I’m still undecided. Thanks again to all my Patreons and YouTube members for supporting the channel directly!

Get the products shown:

Elegoo Mars

If it’s out of stock there, try some other countries, like Spain or China

VAT Pack

Resins

UV LEDs mentioned

💙 Enjoying the videos? Support my work on Patreon!

Product links are affiliate links – I may earn a commission on qualifying purchases (at no extra cost to you)

Check out my second channel “More Layers” on YouTube for livestreams