I’ve reviewed quite a few filaments in Filaween 1.0 – here’s what I learned and what’s to come!

There is a lot of half-knowledge being circulated when it come to material choices for your regular filament-based 3D printer. I’m not claiming that what I’m about to present is the ultimate, final answer to everything, but after trying over 30 materials in the Filaween series, all with the same set of tests, I think I have a decent understanding of what’s going on. We’re going to check out which filaments disappointed me the most and which ones turned out to be my favorites. And we’ll try and see if there is any general correlation when it comes to what filaments are better or worse for specific jobs.

So let’s start with what Filaween was supposed to be all about: It’s a series of filament reviews all done with the same conditions for each material. It was never meant to be scientific, because even just running each material through a tensile testing machine with the proper setup and a sample size larger than one would have meant that I’d have tested maybe two instead of thirty materials.

And without the proper setup, I didn’t want to sell off my results as properly scientific, so… I didn’t.

The strength rating I gave filaments didn’t use N/mm² or Megapascal, which is the proper unit for yield strength or tensile strength. I’m sure my combined ratings in kg do have an excellent correlation to the filament’s yield strength, but again, my intention was never to oversell the results. That being said, the numbers definitely let you compare one filament to another and I did find that these simple tests are an excellent indicator of how a material will perform with real prints.

So let’s check out what those results were, shall we? All the raw data is still available in the Filaween “wall of data” spreadsheet if you want to dive into them yourself.

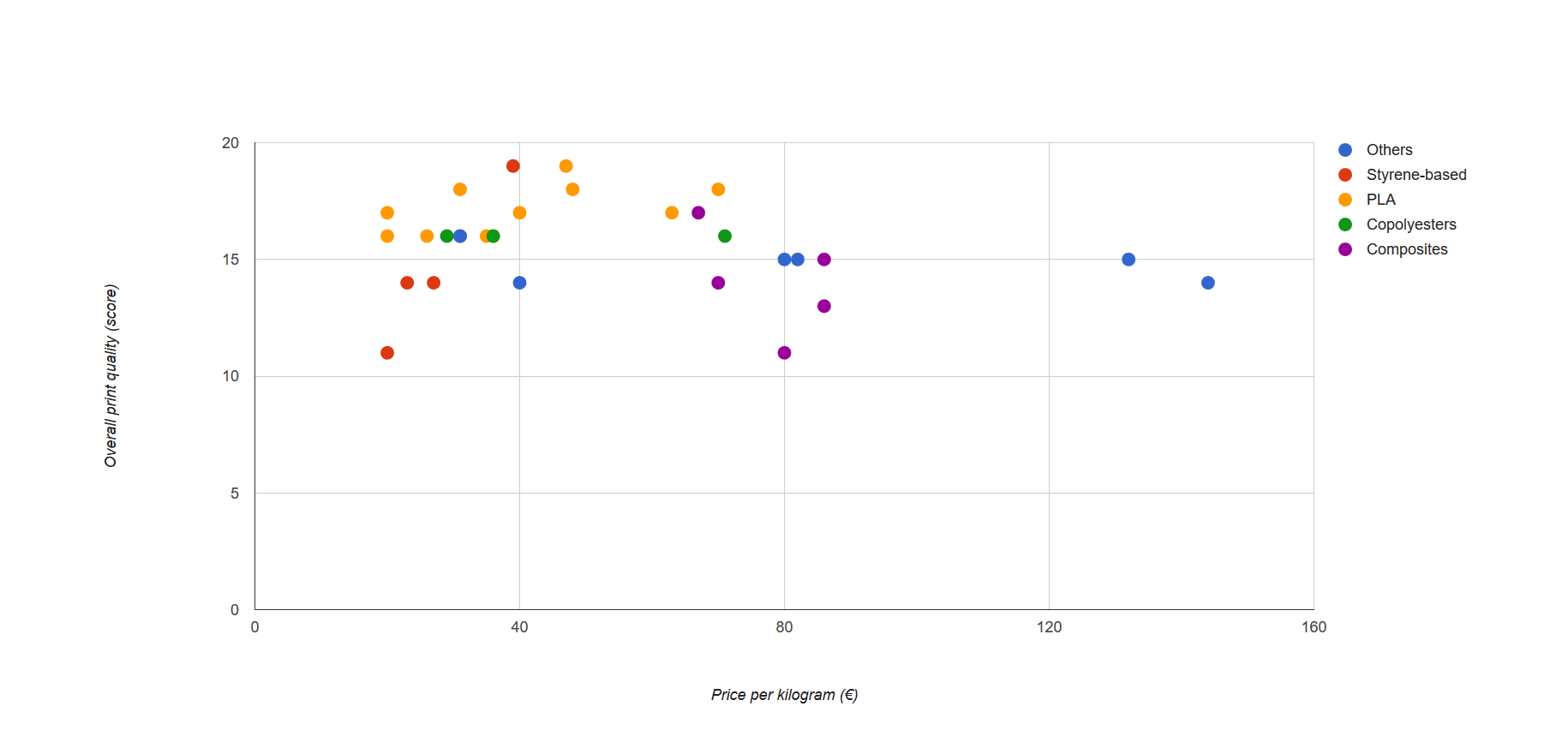

Let’s start out with price to performance. Do more expensive filaments actually get you nicer looking or stronger prints? Not really. In these charts, the further to the right a data point ends up, the more expensive the filament is, and the further up in the charts is ends up, the better it performed, in this case, that means better print quality out of the box. Keep in mind that the regular filaments tested in Filaween season one were priced between 20 and 144€ per kilogram including tax. This means it’s all brand-name filament, and not off-brand stuff that might vary heavily from one batch to the next. And in this range, even the cheapest filaments at 20€/kg performed very well. The yellow dots here are PLA, which has a grouping in the low- to mid-price segment and always ended up with 16 or more points for quality, which is perfectly usable and will make for awesome prints, maybe with a tiny bit of tuning.

The red dots here are the styrene-based filaments, so ABS or ASA. This would also include materials like HIPS, clear MABS or SAN, but I didn’t test any of those for Filaween yet. The one point at the very top is ASA, the others are ABS, and while they’re also in the low-price segment, they did generally end up with a lower print quality. Green dots are copolyesters, I didn’t test a ton of them, but they all printed equally well and will work for all but the most challenging prints.

Purple dots are composites, that is PLA-based, Nylon- or Polyester-based materials with some sort of chopped fibers or particles. They all group up in the 80€ per kilogram range, and most end up with a few more print quality issues that will need a bit of extra attention when tuning in a print profile. The rest of the materials are plain Nylons, Polycarbonate and Flexibles, but for a lack of data points, I’ve grouped all of those as “Other”.

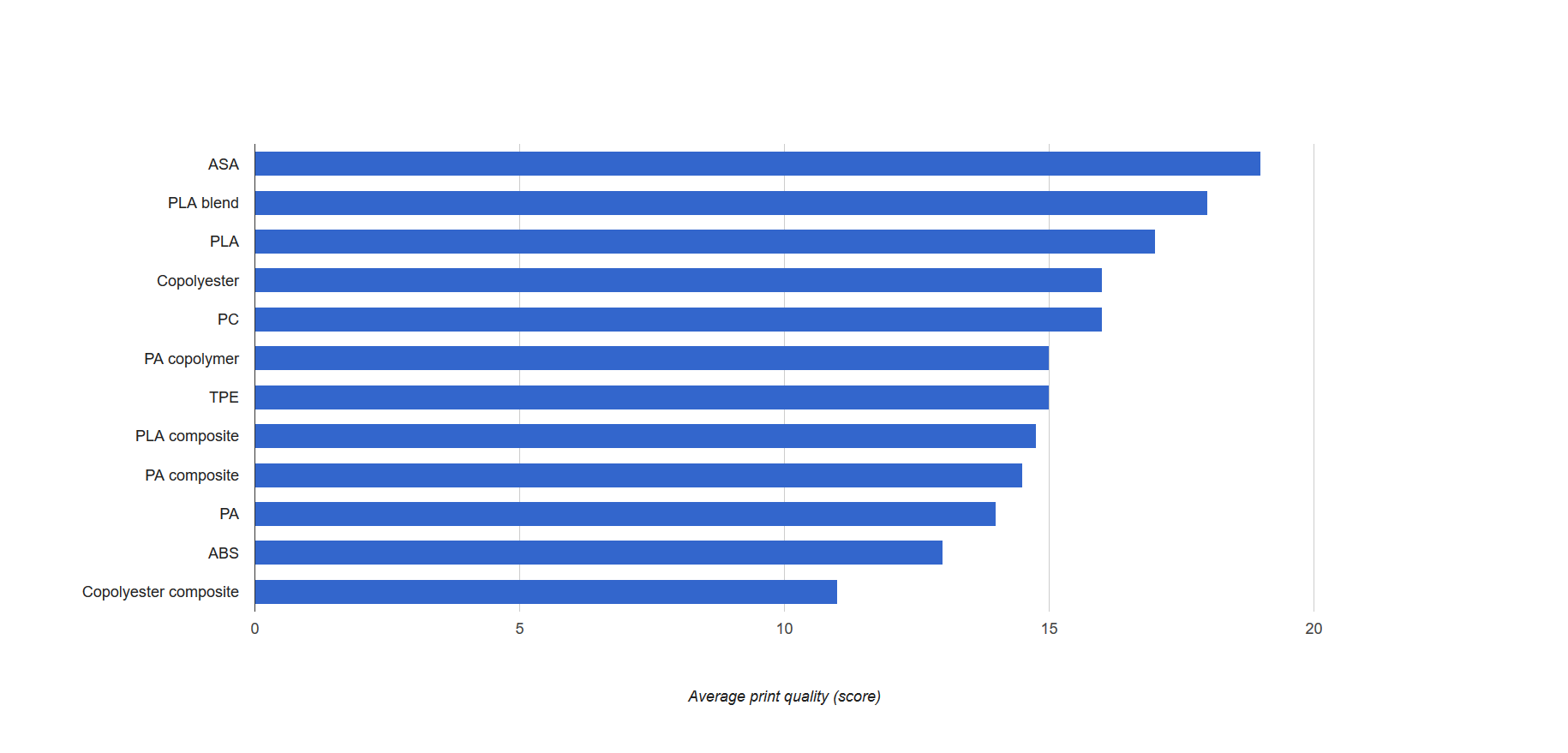

So to recap: So far, ASA produced the best print quality, which is a material from rigid.ink, closely followed by the PLA blend, which is Colorfabb PLA/PHA, then general-purpose PLAs, copolyesters aka PETGs and polycarbonate and Nylon. The composite materials all came in in the lower half of the scoreboard, as did standard Nylons and ABS.

So it looks like if you’re just looking for a material that prints great and is easy to use, common PLAs are actually your best best. Composites like wood-filled materials also have a great feel to them and can make simpler prints look amazingly organic.

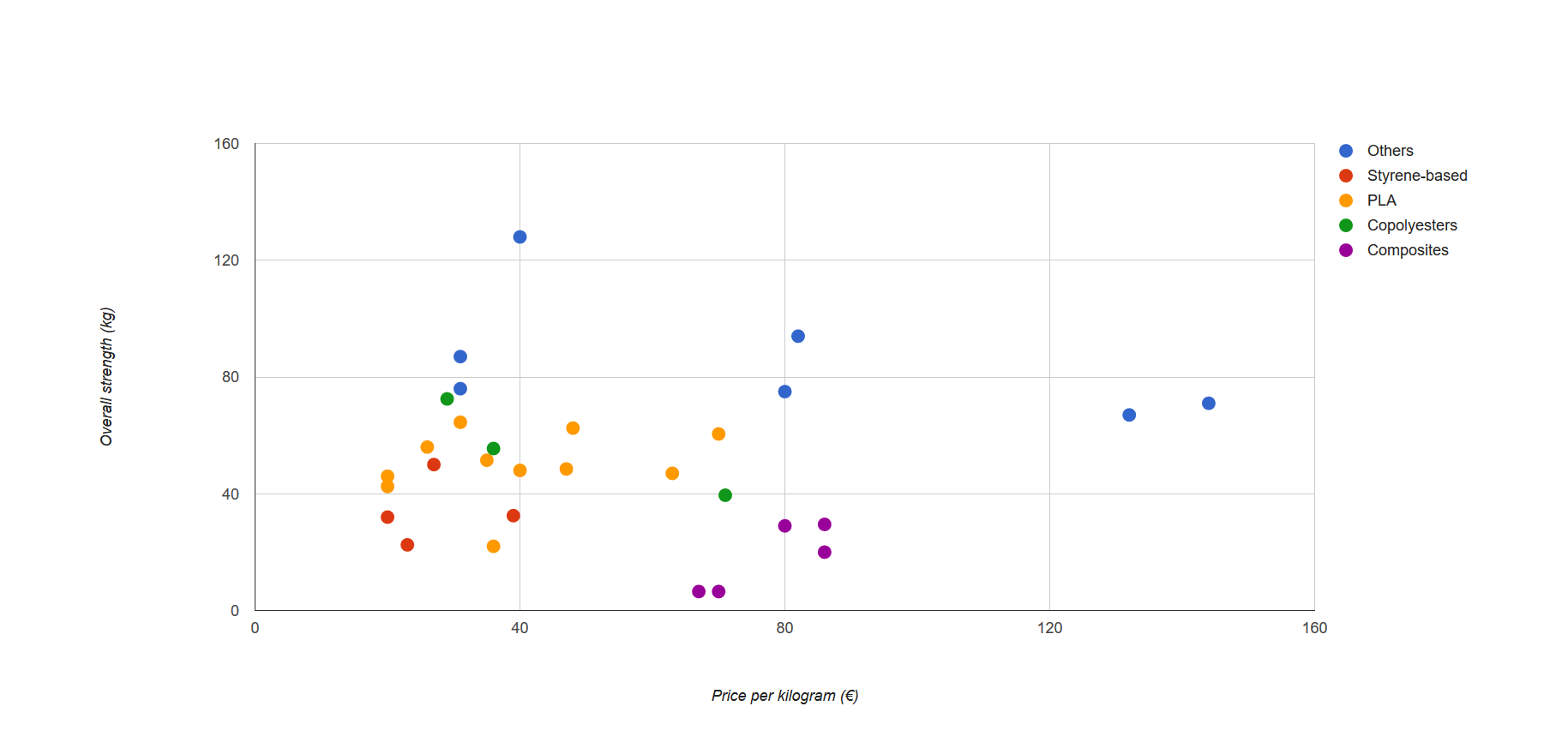

But print quality wasn’t the only thing I tested for, I also checked for how strong parts will typically turn out. These tests are purely looking at ultimate tensile strength, they’re not checking for impact resistance or whether a material stretches a lot before it fails or whether it just snaps off. So while the results are pretty good, I think, keep in mind that there is a bit more to how tough a material ultimately ends up being.

Starting with the PLAs again, we get a pretty good grouping in the medium to high strength region, but it’s basically independent of price. The one outlier is rigid.ink’s PLA+, which was a bit of a letdown in the ultimate strength department, but it’s also a weird modified PLA, which are materials that are still somewhat new to the market. Other than that, the cheapest PLAs are almost exactly as strong as the most expensive one. It’s much of the same story for ABS and ASA, the red dots, while copolyesters are a bit all over the place. The most expensive one was also the weakest, but with just three data points, I don’t think we can really call that a trend yet.

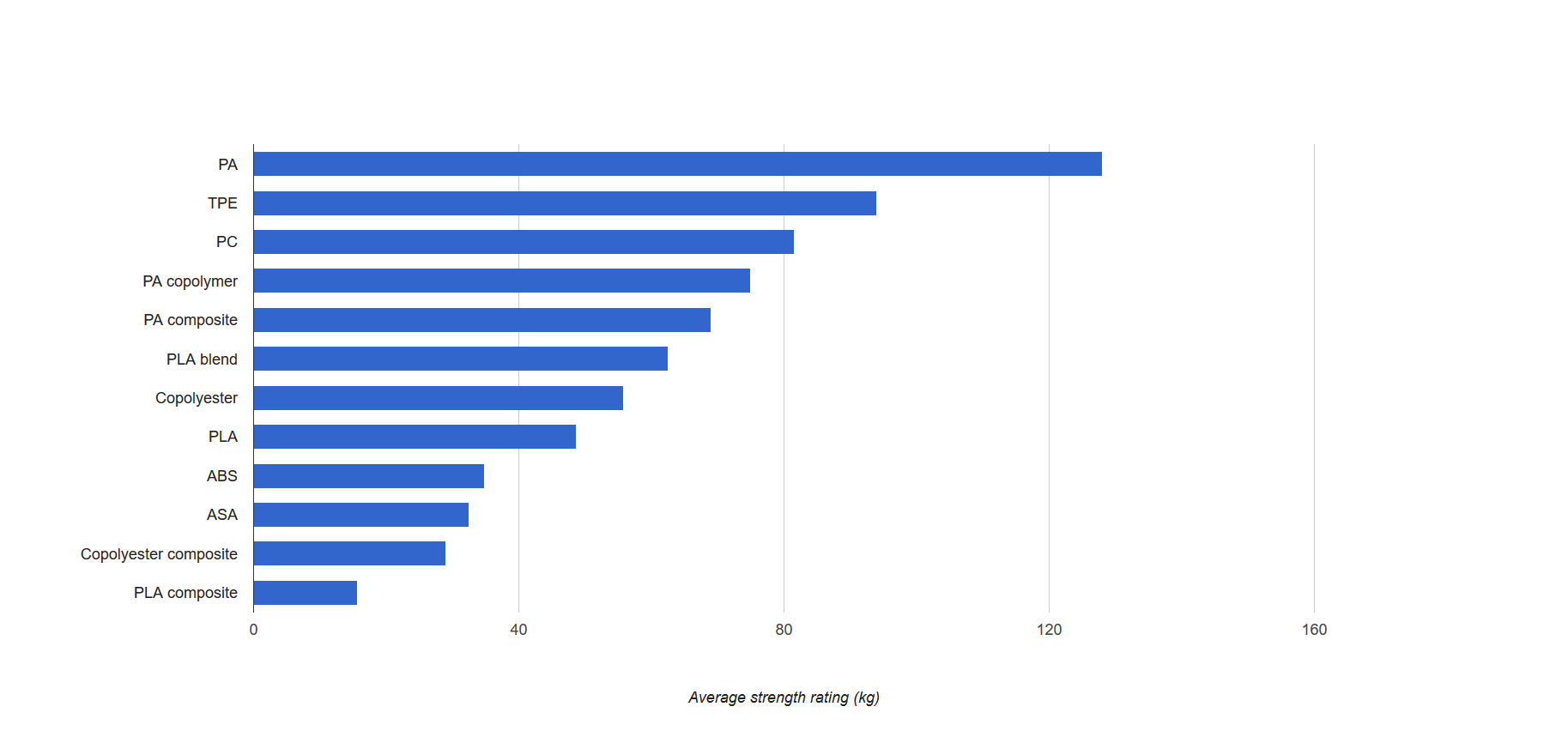

So if we look at strength independent of price, the two softer types of filament easily take the lead. Nylons take the top spot with the maximum possible score in these tests. My setup just didn’t have any more headroom to actually break these materials. The Nylons are followed by TPE, which is flexible filament that will deform a ton before breaking. Next up is Polycarbonate, which is a regular rigid material, I actually like that stuff a lot, if only it were a bit easier to print…. [eye the PC-Plus].

Then we have Nylon copolymers like Taulman’s 910 and Nylon composites, both carbon-filled, which are rigid.ink’s Carbonyte and Matterhackers’ NylonX.

Between PLA, Polyesters and ABS, the polyesters are a bit stronger than PLA on average, while the ABS filaments fell way short of both. ASA, while printing well, doesn’t quite reach the strength even of ABS. Composites other than the Nylon-based ones are, on average, weaker than their base material, even when they are filled with technical fibers like chopped carbon. They might be somewhat stiffer, and come with a very pleasing surface finish in my opinion, but I wouldn’t use them for parts that need to be particularly tough.

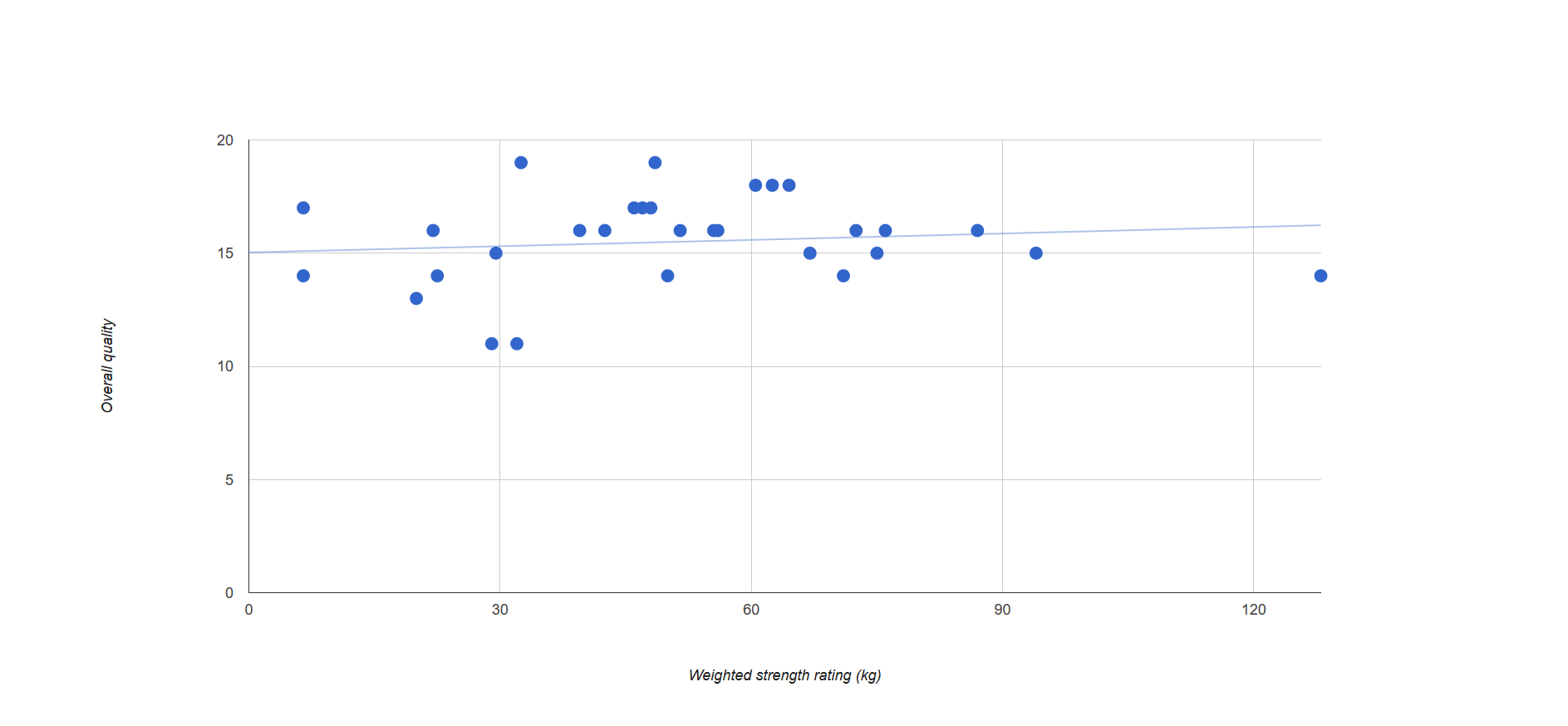

Ok, so I do have a ton of data that we could turn into all sorts of charts. For example, we can look at strength vs. print quality:

With a bit of fantasy, you could make out something that looks like a correlation between the two, so you could say that strong materials have a better chance of also printing well.

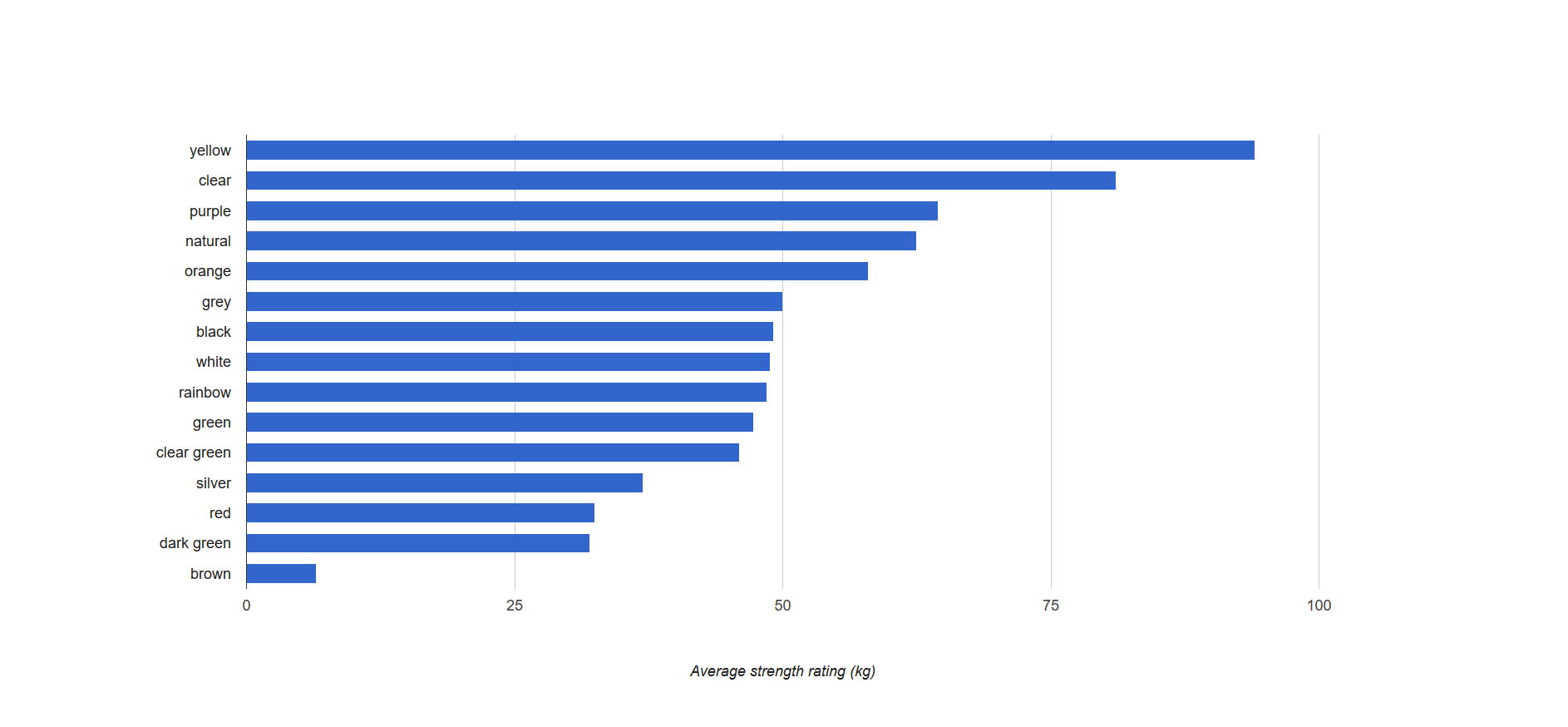

Or we could pull up color vs. strength, again, this is across all materials, and it looks like yellow filaments are way stronger than everything until you realize there was only a single yellow material, which was Polymaker’s PolyFlex, so I don’t think there’s currently enough data to support any color correlations, but I’m sure some site is going to use this exact graphic and turn it into an article like “Racist YouTuber claims yellow filament is better than brown material.”. Though if you look at white and black filaments, they are actually really close.

Now, I didn’t do a huge amount of tuning for any of these materials, instead I relied on the manufacturer’s data as much as possible. After all, that’s how most users are going to use these filaments, not everyone wants to or even knows how to tune in a filament perfectly. I know that some filaments would have received better ratings if the print profiles were a bit better tuned, but for the sake of consistency between tests I didn’t want to start tuning filaments more half way through the season, that would have skewed the entire rating system. I started like that and I wanted to finish like this, at least the first season.

But I have to say, not a lot of manufacturers are all that good at giving all the relevant print settings, which, I mean, if you’re printing a PLA probably doesn’t matter all that much, but when you have something like a highly modified PETG or Nylon blend, chances are you’re not just going to have a perfect profile sitting around for that exact material.

The information I would consider the absolute minimum a manufacturer should include are these:

- A recommended print and bed temperature that works for a standard setup like an E3D v6, and then maybe a temperature range that is reasonable if you want to tune for quality or part strength.

- Next, bed surface recommendations that are known to work well, like using gluestick for Nylons or staying away from glass for polyesters or PEI for flexibles because both of those combinations will tear chunks out of the bed when you try to remove prints.

- Then, the one that very few manufacturers actually include, is part fan settings. I’ve had to ask quite a few manufacturers for their recommendation there because the info just wasn’t available publicly. And that’s a really crucial setting, if you’ve ever printed PLA without a fan or ABS with the part cooling fan turned on you’ll know how much of a difference that can make. To make matters worse, many of the filaments didn’t fit into those two material groups, so I honestly had no clue whether I should use a fan or not with some materials.

It might not even be a single set of setting that is perfect for everything, for example Innofil Pro1 actually provides three sets for you to use depending on what you’re going for. Hats off for that! Other manufacturers sometimes give a huge temperature ranges like 195° to 245°, and I guarantee you, whatever you’re printing is going to feel like a completely different material between those two temperatures.

Overall, the filaments I was most disappointed in were the PLA and PETG composites – they feel and look good or at least unique, but require extra tuning to print well. Worst of all, the extra fibers don’t even translate into any extra strenght, they actually seem to make the finished prints weaker, which kinda defeats the point, I think. However, the two carbon-filled Nylon filaments I tested, Matterhackers Nylon-X and rigid.ink Carbonyte, seem to work much better overall. They’re incredibly similar materials, they print and perform almost identically, and even though they are expensive, printed parts are strong, rigid and tough. That’s basically the trifecta of properties you want in a functional material, so I keep using them wherever I need something that is exceptionally robust. The other material that is rigid and strong is PETG, I really like the one from DAS FILAMENT, though the others aren’t far off. While the numbers seem to indicate that it’s just as good as the Carbon + Nylon materials, it’s not quite as tough as those. As we’ve seen in the “Which filament is bulletproof” video, PETG is one of the materials that likes to shatter most violently on impact, and I’ve seen something similar in a lot of real prints, too. It’s fine as long as you use it within its comfort zone, but as soon as you go beyond that, it cracks really easily.

The biggest surprise to me was how consistent the standard PLAs performed. Whether it was a budget or a super-premium material, they all printed well and made for reasonably strong parts. There are some slight differences, but there wasn’t any single material that I’d consider unusable.

The other materials I was really impressed with were the Nylons, most of which are made by Taulman. They are a bit softer than other materials, but that’s what makes them so tough. Also, Polycarbonate, that stuff actually printed really well, even though it likes to warp, but the parts turned out amazingly strong.

I also do like the ASA, which feels exactly like ABS, isn’t as strong, but it prints a lot better than the ABS materials I’ve tested. And when it comes to aesthetics, the multi-color Unicofil actually makes for awesome effect, and it’s a well-performing PLA, too, so it’s just a gimmick. Well, ok, it kind of is. The Primaselect Wood-filled PLA, I think, is a great-looking material, but you definitely shouldn’t use it for anything that should be load-bearing.

So I think Filaween 1.0 was a great series, even though it wasn’t, like, the most complete set of tests, I think there’s still great value in having something to compare one filament to another. Filaween will return with a second season, right now I’m working on figuring out what tests to include and on making the results more relatable. That’s going to be its own announcement video where I explain how the tests are set up, what they test for and also what the new procedure for tuning in a material is going to be. Until then, I hope you enjoyed Filaween 1.0 and learned a bit about what the different materials are good for.

Buy the materials mentioned here:

Matterhackers NylonX

rigid.ink Carbonyte

DAS FILAMENT PETG

DAS FILAMENT PLA

rigid.ink ASA

Polycarbonate

Taulman 910

3D Prima Primaselect WOOD

📘 Compare all #Filaween test results